TO THE INSTALLER

It is necessary to ensure that there is sufficient air flow through each furnace after the add-

on installation has been completed. It is suggested that the temperature rise method be

used since most installers are likely to have the necessary equipment. The temperature

measurements may be made using a potentiometer and thermocouples, mercury thermome-

ters. If thermometers are used, sufficient time must be allowed for the thermometer to reach

actual temperature. As much as twenty minutes may be required.

PROCEDURE

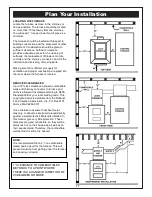

To check the existing system, drill a hole 1/4” in the side of the return plenum on the primary

furnace and a similar 1/4” hole in the side of the main supply air duct, 24” from the supply air

plenum. Insert a temperature measuring device in each of these holes and start the primary

furnace. Allow the furnace to operate until all temperatures have stabilized. This will take at

least 1/2 an hour. Read the two temperatures thus obtained and not the difference, TS - TR.

(see diagram 1, page 18). This difference should not exceed 85 degrees F. (29° C)

Complete the installation of the Jack as an add-on furnace and drill a third 1/4” hole in the

TA (See TA, page 18). Insert a temperature measuring device.

Operate the primary furnace until the temperature rise TA - TR across the primary furnace is

equal to or less than 85 degrees F (29° C). Should this temperature difference exceed 85

degrees (29° C), increase the blower speed until the temperature rise TA - TR is equal or

less than 85 degrees F (29° C).

Shut off the primary furnace and build a fire in the Jack unit. When the fire is established, fill

the fire box to the top of the firebrick (maximum level). Open the combustion blower air

damper. Allow the temperature to stabilize and measure the temperature difference TS - TR.

Should it exceed 85 degree F (29° C), a further increase in blower speed will be necessary.

Once the proper air temperature rise has been obtained, an ammeter should be connected

to the blower motor to measure current draw. If it exceeds the name plate rating, change the

motor to a higher rating (if the old motor was a two stage, ensure that the new motor is as

well). It is permissible to change the blower motor and blower drive pulleys in the primary

furnace but not the blower unit.

This equipment must be installed according to the manufacturer’s instructions and in a man-

ner acceptable to the regulatory authority having jurisdiction by mechanics experienced in

such a service. When required by regulatory authority, such mechanics shall be licensed to

perform this service.

Safety Statements

8

Summary of Contents for SUPER SJ125

Page 11: ...3 1 2 4 5 6 7 8 9 Furnace Features SJ125 ...

Page 13: ...1 2 3 4 5 6 7 Furnace Features BJ90 13 ...

Page 46: ...SUPER JACK SJ125 Exploded Views Parts Lists 46 ...

Page 48: ...BIG JACK BJ90 Exploded Views Parts Lists 48 ...

Page 53: ...Notes ...

Page 54: ...Notes Notes ...

Page 55: ...Notes ...