M

AINTENANCE

d) Coat the vanes lightly with high-

performance grease and insert into the

rotor slots with the starting aids.

e) Coat the entire braking piston surface, in-

cluding the brake piston seal, lightly with

high-performance lubricant and push

the brake piston into the internal cylinder

with the braking surface first. Note the

position of the eccentric bore.

f) Insert the brake springs into the bores of

the brake piston.

g) Loosen adjustment bolts

(14)

and lock

nuts

(15)

. Screw back adjusting bolts

sufficiently.

h) Apply high-performance grease lightly to

rotor bearing (needle bush) in the motor

cover and install motor cover. Ensure

correct seating of the brake springs and

the locating pins to the motor housing

and to the brake piston.

i) Do not tighten the four adjusting bolts

after bolting the motor cover in place,

only screw them in loosely by hand to the

stop in the cover. Screw back the lock

nuts sufficiently beforehand.

j) Then screw back the adjusting bolts

45

◦

from the stop, hold and lock with

the nuts. For lifting heights of 10 metres

(33 feet) and more, a setting of up to 60

◦

may be required. For operation in areas

with ambient temperatures exceeding

30

◦

C (86

◦

F), the adjustment must be

carried out with the device warmed up

accordingly.

k) Tighten the nameplate

(1)

.

5. Check the braking action under nominal load

(run in the brake by performing several hoist-

ing cycles, then assess) prior to initial opera-

tion. Check the motor power. In the event of

low motor power, regulate the adjusting bolts

again.

8.20. Replace chain

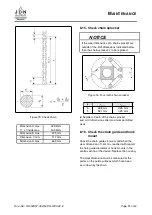

WARNING

Danger from chain fracture

The chain is subjected to impermissible stresses if

the chain is twisted.

I

Do not twist the chain!

NOTICE

JDN chains are matched in close tolerances to

the sprocket. In order to ensure an optimum func-

tion of the chain and in order to prevent dangers,

only genuine JDN chains may be installed.

NOTICE

If the chain end link of the load chain is positioned

incorrectly, it must be removed. The following

chain link will then be positioned correctly.

The spare parts list contains information about

torques and other representations of the indi-

vidual components.

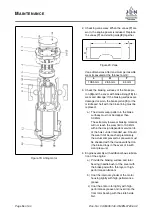

1. Loosen the chain from the dead end chain

mount

(9)

.

2. Remove components on the idle chain

(1)-(3)

:

a) Loosen the screw connection or drive out

the dowel pin.

b) Pull the buffer disc with edge

(3)

(edge

encloses the buffer), buffer

(2)

and buffer

disc without edge from chain.

3. Remove the load sleeve and buffer

(4)-(8)

:

a) Drive the dowel pin

(5)

out of the load

sleeve.

b) Remove the chain end link from the

chain pocket.

c) Remove the buffer

(6)

and buffer discs

(7)

from the chain.

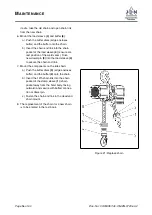

4. Attach the new chain to the end link of the

load section of the old chain after aligning the

welds by means of an open chain link. The

welds on the upright chain links must face out-

wards when running over the chain sprockets.

5. Switch

PROFI 3 TI

to Lifting and run the new

chain through the drive chain sprocket. After

Doc.-No.: VA053957-40-OM-EN-0720-60-2

Page

55

of 60