M

AINTENANCE

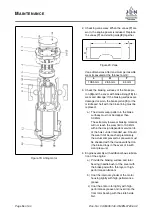

8.13. Check lowering limiter

WARNING

Danger from chain fracture

If the buffers are damaged, inadmissibly high

loads may act on the chain upon actuation of the

lowering limiter. The chain may break.

I

Do not use the product

I

Have the product repaired (replace buffer)

1. Move the unloaded load hook until just short

of the lower end position.

2. Stop immediately before reaching the end po-

sition and then carefully (by repeatedly press-

ing the control element) move to the end posi-

tion.

3. The movement of the chain must be stopped

due to deformation of the buffer. The engine

will stall in the process.

4. Following successful testing, the buffer must

be unloaded.

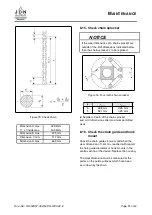

8.14. Check chain

WARNING

Danger from chain fracture

If the chain of your product

PROFI 3 TI

has one

of the features listed below, the chain may break

upon further use.

I

Do not use the product

I

Replace the chain

•

Corrosion pitting

•

Bent or damaged chain links

•

Chain drawn tight

•

Wear over 11 pitches (dimension A)

•

Single pitch wear (dimension B)

•

Diameter reduction of a chain link (dimension

C)

•

Elongation of a chain link (dimension D)

Check the entire length of the chain. When check-

ing the replacement limit, future wear up until the

next inspection date must be taken into account.

If the chain dimension values are outside the limit

values specified in the table when checked, the

chain has reached its replacement limit and must

be replaced by a new one.

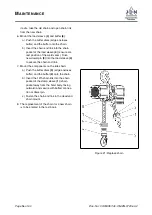

The chain sprockets must also be replaced to-

gether with the chain, as otherwise the new chain

will be subjected to increased wear. Each chain

replacement must be documented in the inspec-

tion log.

Please observe the information contained in

,

→

DIN 685, Part 5

,

→

ISO 7592

Page

50

of 60

Doc.-No.: VA053957-40-OM-EN-0720-60-2