PR_I020/2023-08-11-EN

Revision: 5

3

Introduction

Save these instructions.

This manual describes the

operation and installation of J.A. Roby woodstove model:

Ultimate Tor. This appliance responds to CSA B415.1 with

sized controlled cord wood. The capacity of this appliance is

from 16 650 BTU/h to 59 262 BTU/h.

Read all instructions carefully before installing your new J.A.

Roby stove. A good installation is very important for a safe and

effective use of this appliance. If you have doubts about the

instruction to install your appliance correctly, we suggest

calling a professional installer. A wrong installation may result

in a fire, burns and possible death.

Keep these instructions for future reference.

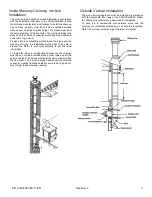

This appliance must be connected to:

•

A HT type factory-built chimney approved UL103 or ULC

629 with 6 inches diameter (15.24 cm);

•

A code-approved masonry chimney with a flue liner with a

6 inches diameter (15.24cm).

Listing and code approvals

Appliance certification

The Ultimate Tor. Magnum and Master wood stove meets the

CSA B415.1 cord wood emission standard.

This appliance also meets:

•

ULC S627-2021 Standard for Space Heaters for Use

with Solid Fuels;

BTU & Efficiency Specifications

•

LHV efficiency 74.24%

•

HHV efficiency : 68.99%

•

Particle emission 1.30g/h

•

Particle emission 0.04g/MJ

•

Minimum burn rate 1.24 Kg/hr

•

Minimum Heat Output* 16 650 BTU/hr

•

Maximum Heat Output* : 59 262 BTU/hr

•

Vent size 6"

•

Firebox size 3.82 cubic feet

•

Recommended wood length: 20 inches

•

Chamber combustion depth: 24 inches

•

Fuel Orientation: front to rear.

•

Fuel: Seasoned cord wood.

* A range of BTU outputs based CSA B415.1 Default

Efficiency and the burn rates from the low and high CSA

B415.1 emission tests, using cord wood.

Efficiency

The average of the efficiency of the stove is 71.6%. When the

seasoned wood has lower moisture the efficiency will be better.

When the outside temperature is really cold, it is important to

create a good draft in chimney. When the appliance is in the

basement, the chimney is higher than if the appliance would

be in the main living area. The draft will be better because we

have more length of chimney.

Warning

-DO NOT USE CHEMICALS OR FLUIDS TO START THE

FIRE

DO NOT BURN GARBAGE OR FLAMMABLE FLUIDS

If this appliance is in an area where children may be near,

it is recommended that you place a decorative barrier in

front of the appliance.

HOT

WHILE

IN

OPERATION.

KEEP

CHILDREN,

CLOTHINGS AND FURNITURES AWAY. CONTACT MAY

CAUSE SKIN BURNS

N.B: BE WARNED THAT THE LOCAL CODES AND RULES

CAN HAVE MORE SPECIFIC REQUIREMENT THAN THIS

MANUAL. YOU CAN CONSULT A PROFESSIONAL

INSTALLER OR ASK FIRE OFFICIALS OR LOCAL

AUTHORITY ABOUT RESTRICTION AND INSTALLATION

INSPECTION IN YOUR AREA.

YOU MIGHT NEED TO OBTAIN A PERMIT FOR

INSTALLING CHIMNEY AND STOVE.

DO NOT CONNECT THIS APPLIANCE TO A CHIMNEY

FLUE SERVING ANOTHER APPLIANCE.

DO NOT CONNECT TO OR USE IN CONJUNCTION WITH

ANY

AIR

DISTRIBUTION

DUCTWORK

UNLESS

SPECIFICALLY APPROVED FOR SUCH INSTALLATIONS.

THIS APPLIANCE IS BUILT FOR BURNING SEASONED

CORDWOOD ONLY. USE OF ANY OTHER TYPE OF FUEL

LIKE COAL/ CONSTRUCTION WOOD/ TREATED WOOD/

FLAMABLE LIQUID/ TRASH/ OR ANY FLAMABLE THING

CAN OVERFIRE AND DAMAGE THE STOVE.

Summary of Contents for ULTIMATE TOR 2015

Page 4: ...PR_I020 2023 08 11 EN Revision 5 4 Rating plate...

Page 5: ...PR_I020 2023 08 11 EN Revision 5 5 Appliance Dimension...

Page 13: ...PR_I020 2023 08 11 EN Revision 5 13 Firebox configuration and part list...

Page 28: ...PR_I020 2023 08 11 EN Revision 5 28 Annex 1 Door assembly Square Door Arc Door...