PR_I020/2023-08-11-EN

Revision: 5

14

General stove installation steps

Location considerations

We recommend installation of this appliance by a certified

installer.

Consideration must be given to:

➢

Safety;

➢

Traffic flow;

➢

Convenience;

➢

Chimney and chimney connector required;

➢

Draft.

Drawing your installation plan on paper is a good way to

avoid mistake.

THESE STOVE MODELS ARE NOT

APPROVED TO INSTALL IN AN ALCOVE

Write on the plan:

•

Exact dimensions for clearances to combustible

material;

•

Exact dimensions of the floor protection;

•

Measurements of the chimney location. (If it not already

installed. Be sure to have all clearances recommended

by the factory-built chimney manufacturer to pass

through the ceiling and roof).

We recommend that a qualified building inspector and your

insurance company representative review your plan before

and after installation.

General steps of installation

1) Read the entire installation manual before installing

and using your stove.

2) Choose a spot where to install your stove. Read

section about floor protection dimension, localisation of

stove over the floor protection plate and combustible

material clearance. Once you have decided where to

install the stove, mark the roof at the center of chimney.

o

To be sure that the vertical center of the chimney,

use a plumb line and mark the center on the floor.

3) Check if it possible to pass chimney without damaging

the structural integrity of your house. If so, you have to

move the location of the stove while keeping the

minimum clearance or more to be sure. If you can’t

move the stove and have to cut through a beam, make

sure to keep the structural integrity of your house by

following state of the art and National building code.

o

We recommend installation of this appliance by a

certified installer.

Note

:

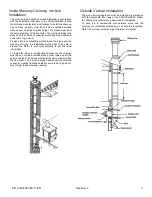

This appliance has to be connected to 6 inches

(15.24 cm) factory build chimney HT UL 103 or CAN/ULC

S629 compliant or a 6 inches (15.24 cm) masonry chimney

with a homologated sleeve inside. Do not install the

chimney directly at the outlet of the appliance. A chimney

connector (flue pipe) is required unless the appliance is

specifically approved for that type of installation.

4) Install the chimney following the manufacturer

instruction.

5) Put the stove directly on the floor aligned vertically with

the center of chimney and trace the side of the stove

on the floor and remove it.

6) Trace the dimension of protection plate on the floor.

There must be 8 inches (20.3 cm) clearance from the

side and the back of the stove. From the front of the

door opening, there must be a clearance of 18 inches

(45 cm). If the space heater meeting the requirement

of CAN/ULC S627 is suitable for installation on a

combustible floor and do not require radiant floor

protection.

7) Install the floor protection plate inside the mark (It must

be non-combustible).

8) Put the stove on the protection floor plate and respect

the offset clearance set at step 6. Be sure to center the

stove under the chimney. We recommend to fix the

stove to the floor with bolt in the slot made for this

purpose in the legs. In a mobile home, it is obliged to

fix the stove.

9) If you have an outside air inlet, you must use 4 inches

(10.16 cm) flexible aluminum pipe. The pipe must be

sealed with thermal resistant sealant and it has an air

intake with grate approved for this purpose.

10) Install the chimney connector on the stove. The pipe

must be fixed with at least 3 screws on the stove collar,

each chimney connector and the chimney collar.

Note

:

The single wall chimney connector must be 6 inches

diameter and have a minimum thickness of 24 gauge (0.025

inches 0.64 mm). Do not use galvanised steel chimney

connector.

.

Summary of Contents for ULTIMATE TOR 2015

Page 4: ...PR_I020 2023 08 11 EN Revision 5 4 Rating plate...

Page 5: ...PR_I020 2023 08 11 EN Revision 5 5 Appliance Dimension...

Page 13: ...PR_I020 2023 08 11 EN Revision 5 13 Firebox configuration and part list...

Page 28: ...PR_I020 2023 08 11 EN Revision 5 28 Annex 1 Door assembly Square Door Arc Door...