62

5. Operation and Configuration

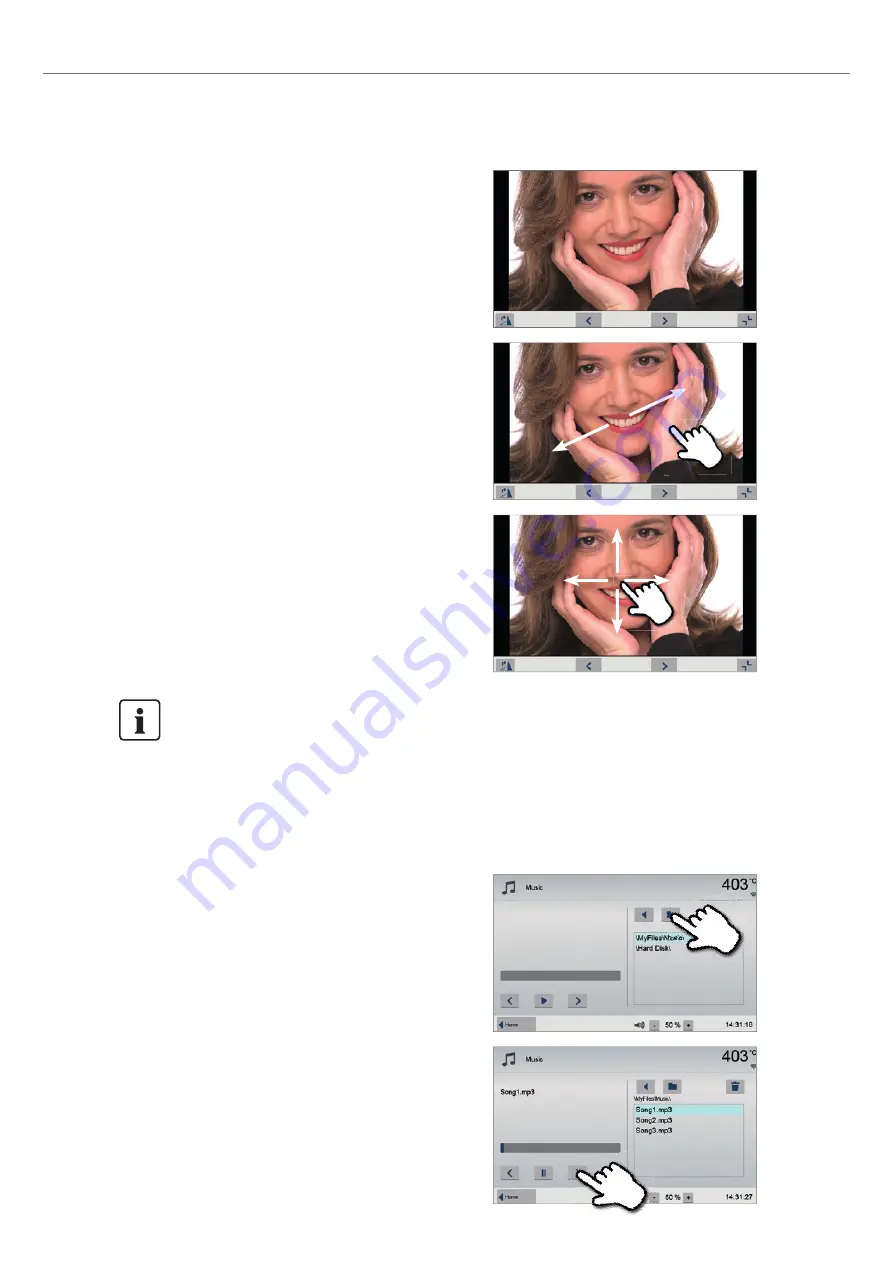

7. Zooming image section

In the full screen view, the image can be enlarged or downsized.

To activate the zoom function, press the touch screen for at least

1 second and move the finger towards the upper right (enlarge) or

the lower left (downsize).

8. Moving the image

An enlarged image can be moved in all directions. For that purpose,

press the touch screen with the finger and move the image in the

desired direction.

2. Selecting music file

The desired music file can be selected on the right side of the

display.

To return to the home screen, press either the touch button

[Home]

in the navigation bar or the Home key on

the membrane-sealed keypad.

5.5.2 MP3 player

Scroll to page 2 in the home screen and press the

[Music]

button.

1. Select folder

The arrow keys are used to scroll through the folder.

The folder can be opened by clicking the

[Open]

button.

6. Full screen view

In the full screen view, you can scroll through the available image

files. The image can be rotated by pressing the corresponding

buttons and the full screen view can be ended.