136

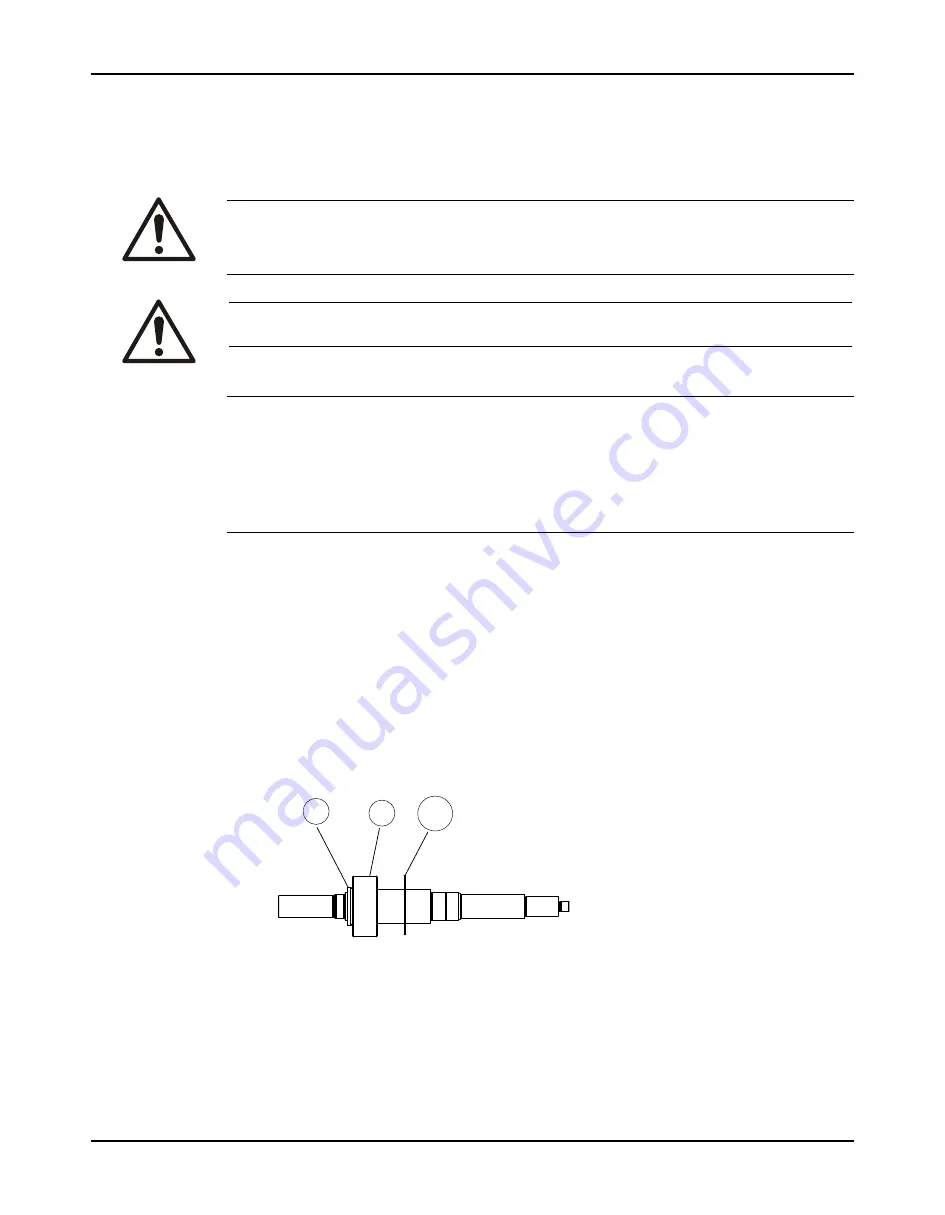

112

361A

Reassembly

Model 710 TruBlue Installation, Operation, and Maintenance Manual

61

Reassembly

Assemble the rotating element and bearing frame

WARNING:

Lifting and handling heavy equipment poses a crush hazard. Use caution during lifting and

handling and wear appropriate Personal Protective Equipment (PPE, such as steel-toed shoes,

gloves, etc.) at all times. Seek assistance if necessary.

CAUTION:

Risk of physical injury from hot bearings. Wear insulated gloves when using a bearing heater.

NOTICE:

• Ensure that the pipe threads are clean. Apply thread sealant to the plugs and fittings.

Failure to do so may result in oil leaks and equipment damage.

• There are several methods you can use to install bearings. The recommended method is

to use an induction heater that heats and demagnetizes the bearings. Bearings can get hot

and can cause physical injury.

1. Install the bearings:

a) Heat the bearings to 100°C | 212°F in an oil bath or with a bearing heater.

b) Clamp the shaft (122) in a bench vise with the thrust bearing surface extending beyond

the end of the vise. Use soft jaws to protect the shaft surface.

c) Install the properly-heated thrust bearing (112) onto the shaft.

If necessary, position a tube against the inner ring of the bearing and gently tap the

tube with a hammer in order to force the bearing onto the shaft. Hold the outer ring of

the bearing in order to prevent vibration damage to the bearing.

d) Apply Never-Seize to the bearing locknut threads on the shaft.

e) Thread the bearing locknut (136) onto the thrust end of the shaft.

The bearing nut is right-hand threaded and is self-locking. It can be reused up to five

times, if handled properly.

f)

Allow the bearing to cool for 10 minutes and retighten.

2. Install the shaft assembly into the bearing frame:

a) Coat the outside of the bearings with oil.

b) Coat all the internal surfaces of the bearing frame (228) with oil.

c) Turn the bearing frame (228) vertically with the larger open end pointing up.