Product Information

7

OPTIONAL FEATURES

The optional features either replace a standard feature or enhance the operation

of the printer. All optional features are installed at the factory and must be

selected when the printer is ordered.

♦

IEEE 1284 Bi-Directional Parallel (Optional)

♦

RS-422 Serial communications interface (Optional)

♦

Custom colors and logo

TECHNICAL SPECIFICATIONS

PRINTING SPECIFICATIONS

♦

Printing method:

Direct Thermal

♦

Print zone:

72 mm. (2.83 in.) wide

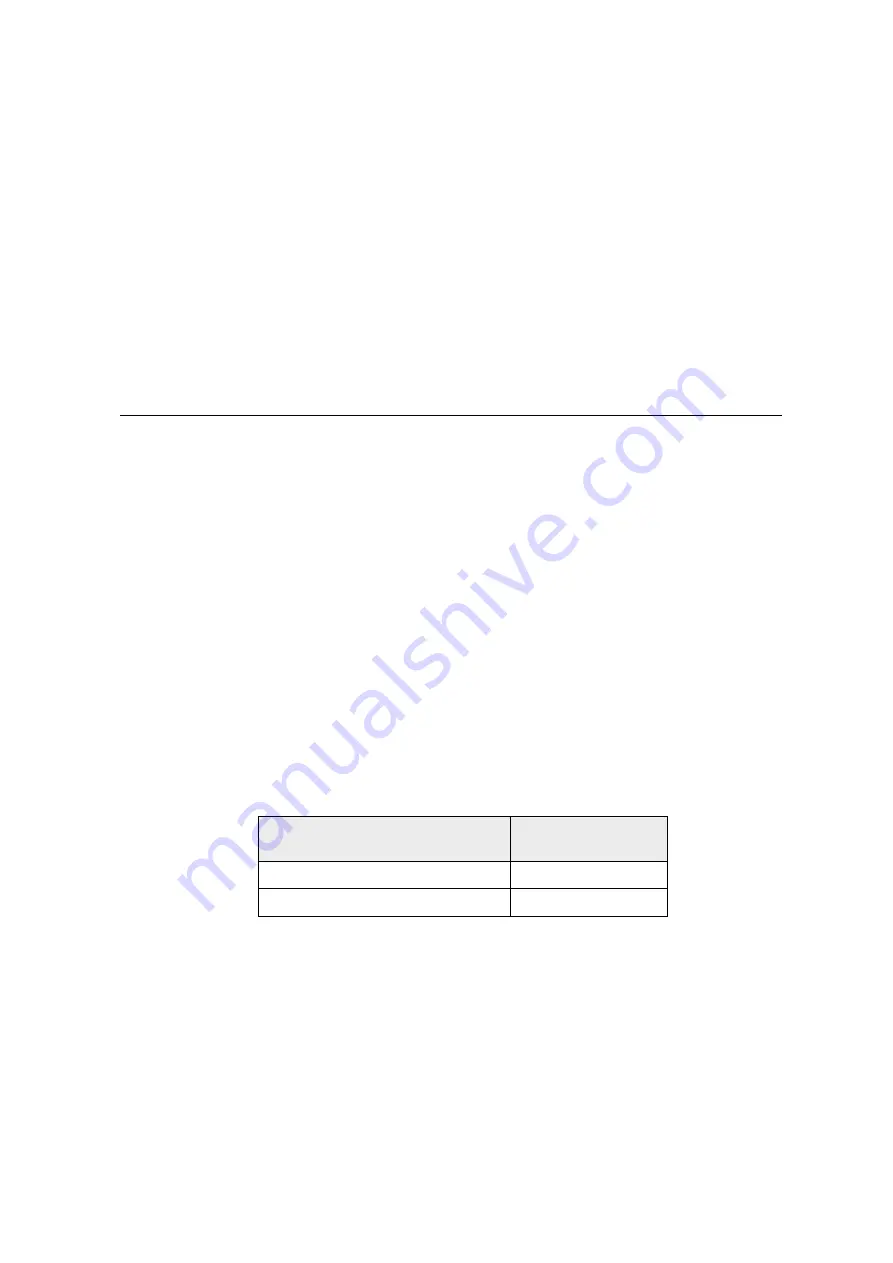

PRINT CHARACTERISTICS

The Series 80 Printer prints characters in a variety of pitches as shown in the

following table and print samples. All pitches are scaleable up to 64 times as

large as the standard size.

For information about programming the printer to print a particular pitch or

style, please refer to the Programmer’s Guide. You can order the

Programmer’s Guide from Ithaca Peripherals. See “Contacting Ithaca

Peripherals” on page 2.

Pitch (Characters per Inch)

Maximum Characters

per Line

15.6 CPI

44

20.3 CPI

57

Summary of Contents for PcOS 80 Series

Page 1: ...A Tr ans actTechnol ogi esI ncopor at ed Com pany...

Page 2: ...Back of cover do not print...

Page 3: ...WARNING To prevent fire or shock hazard do not expose this printer to rain or moisture...

Page 9: ...Series 80 Maintenance Manual iv...

Page 17: ...Series 80 Maintenance Manual 8...

Page 23: ...Series 80 Maintenance Manual 14...

Page 35: ...Assembly Disassembly 27 REMOVING THE OUTER HOUSING 1 4 3 1 1 1 4 2...

Page 38: ...Series 80 Maintenance Manual 30 DISASSEMBLE THE COVER 1 2 3 4 5...

Page 45: ...Assembly Disassembly 37 REPLACING THE STEPPER MOTORS 2 1 3 4 5...

Page 47: ...Assembly Disassembly 39 REPLACING THE SENSORS AND KEYBOARD ASSEMBLY 1 2 3 4 5 6 7 8...

Page 51: ...Appendix A Parts List 43 APPENDIX A PARTS LISTS...

Page 52: ...Series 80 Maintenance Manual 44...

Page 55: ...Appendix A Parts List 47 PRINTER ASSEMBLY 1 3 2 4 5 6 6 5 6 6...

Page 62: ...Series 80 Maintenance Manual 54 MOTORS AND SWITCHES 1 2 4 3B 6 7 4 6 5 4 5 8 3A 4 6...

Page 65: ...Series 80 Maintenance Manual 58 P N80 9408 Rev A 9 97...