27

Starting the Instrument by Inserting a Cuvette

1.

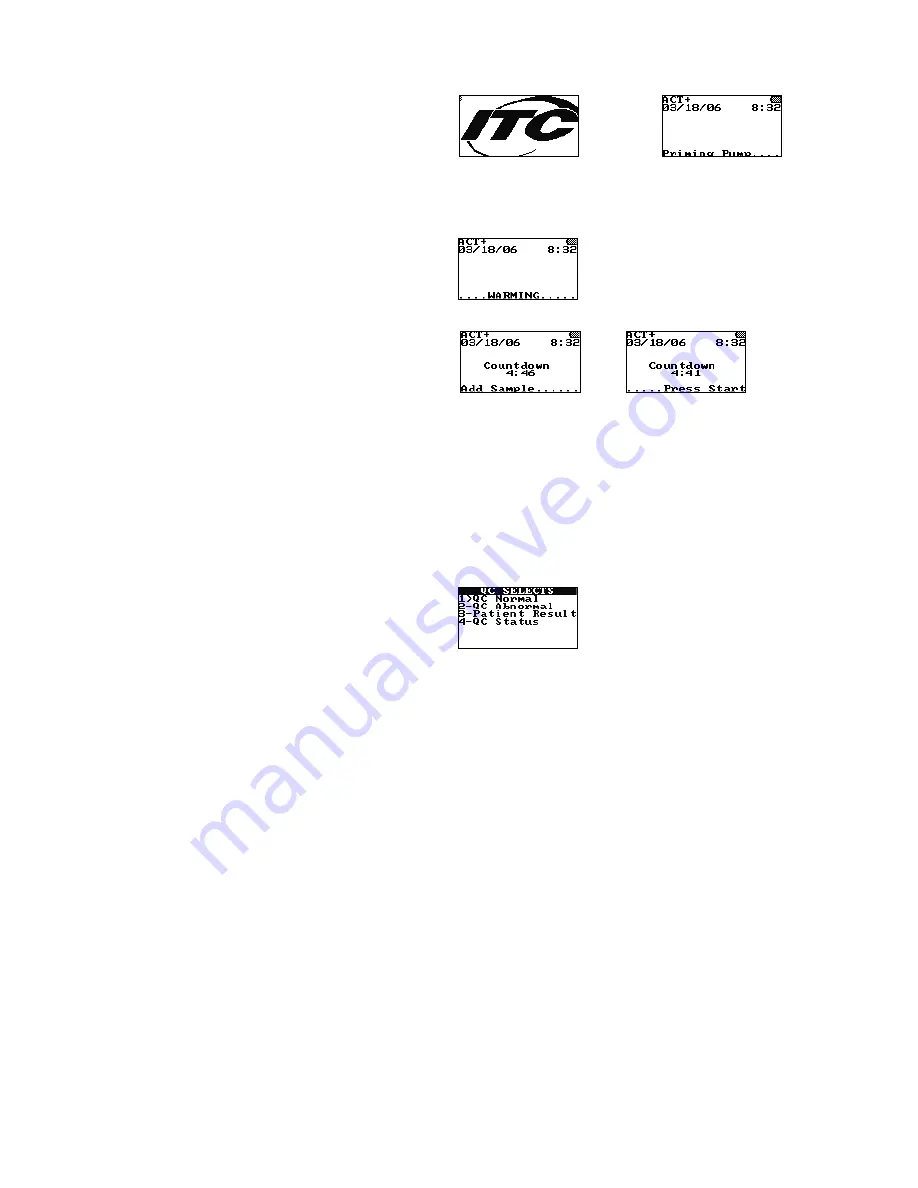

When a test cuvette (e.g., ACT+) is inserted to turn on the instrument, the following prompts are

briefly displayed:

(example only)

followed by

Note

: The test name for the inserted cuvette is displayed in the upper left-hand corner of the

screen. Check the display for fault messages while the cuvette is warming. Refer to the

Troubleshooting section for the procedure to resolve a fault message.

2.

The instrument then warms the cuvette to 37 °C ±1.0 °C:

3.

When the cuvette reaches temperature, the instrument beeps and alternately displays:

and

4.

The sample can now be added. After the sample is added, press

START

to run the test.

RUNNING A TEST

Samples are designated as patient samples by default. If a control is being run, the sample type must be

changed from

patient sample

to

QC Normal

or

QC Abnormal

. If a patient sample is being run, this step is

unnecessary.

Important

: Failure to select

QC Normal

or

QC Abnormal

for a control sample will result in

storage of the control results as patient results in the patient database.

Designating the Sample as a Normal or Abnormal Control

1.

Press

QC

to display the QC SELECTS menu:

Note:

A cuvette must be inserted into the instrument to display the QC SELECTS menu. If entry of

a cuvette lot number and/or Operator ID or PIN is required, this must be done before the QC

SELECTS menu can be displayed.

2.

Press

1

to designate the sample as a

normal control

(

QC Normal

is displayed), or press

2

to

designate the sample as an

abnormal contro

l (

QC Abnormal

is displayed).

Note:

The sample type can be designated either before or during the test, unless QC lockout

features are enabled. Once

QC

is selected, pressing the

QC

key again briefly displays the QC level

and assay being run.

To exit the QC menu, press the CANCEL key.

Important: Once a QC type is selected, it cannot be changed.

Summary of Contents for HEMOCHRON Signature Elite

Page 81: ...81 This page intentionally left blank...

Page 84: ...84 HX1101 0310...