Page of 14

9

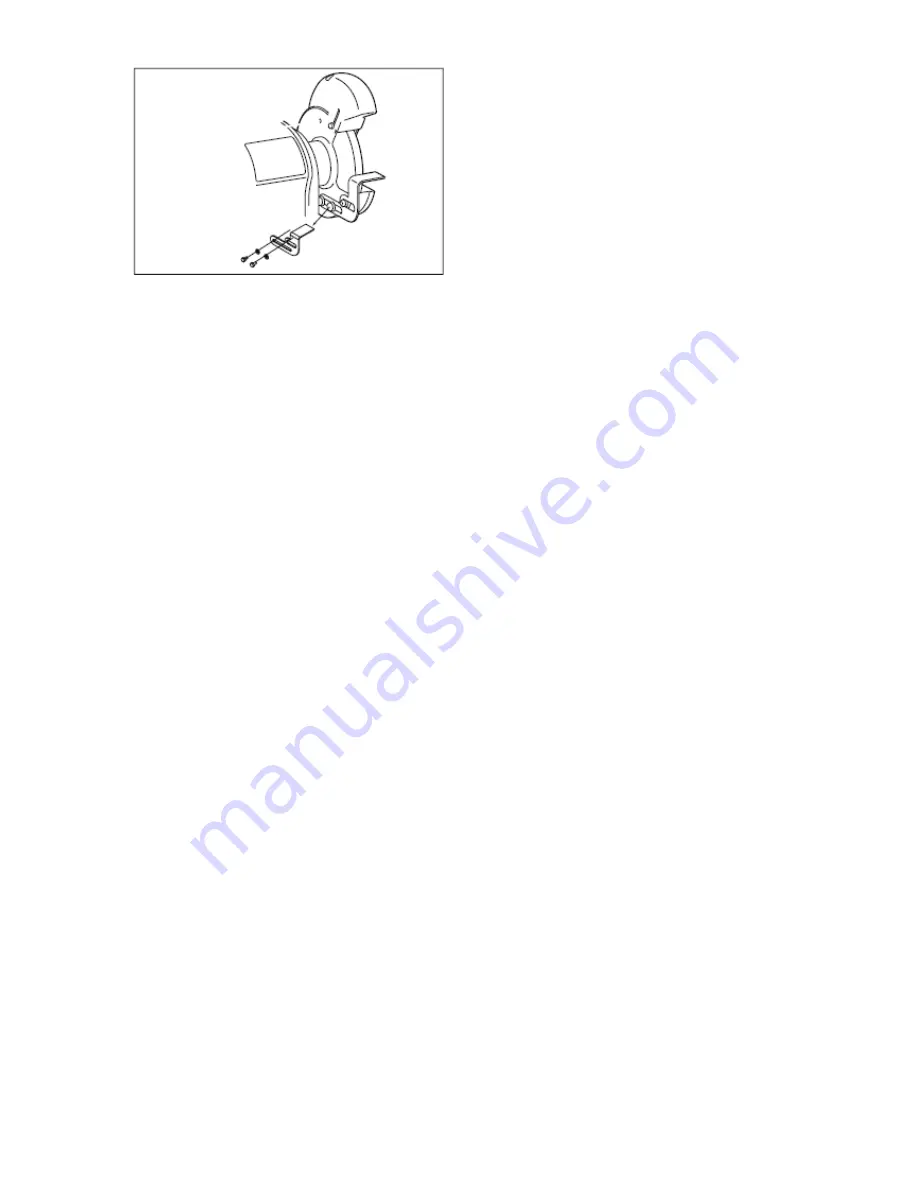

Mount the tool rests to the work rest bracket using the two hex screws and washers.

Before tightening the bolts, adjust the gap between the grinding wheel and the work rest to a

maximum of 1/8in. Tighten securely.

Adjustments

To prevent the workpiece from being pulled and caught between the tool rest and the wheel,

readjust the tool rest position whenever necessary to maintain the 1/8in. distance.

1. Loosen, but do not remove, the two hex nuts holding the tool rest arm.

2. Slide the tool rest in or out to achieve a 1/8in. distance from the grinding wheel surface.

3. Re-tighten the two hex nuts.

OPERATION:

ON/OFF

The rocker ON/OFF power switch is located on the front of the grinder.

1. Press the side marked ON to turn the grinder on.

2. Press the side marked OFF to turn the grinder off.

Grinding

•

Adjust the tool rest to accommodate large or unusually shaped workpieces.

•

Always keep the workpiece moving across the face of the grinding wheel. Grinding

continuously on the same spot on the wheel will cause grooves to be worn into the wheel.

The wheel may crack or become damaged more easily, and grinding of other objects will be

difficult.

•

If the workpiece becomes hot, dip it into water to cool it.

•

Always grind on the face of the wheel (around the diameter), NEVER on the sides. Side

pressure on grinding wheels can cause cracking and damage.

•

If the face of the grinding wheel is worn unevenly, becomes grooved, or is no longer smooth

and flat, the wheel should be reshaped with a dressing tool (not supplied).

•

If the diameter of the grinding wheel is no longer round, the wheel should be reshaped with

a dressing tool or replaced.

•

If the surface of the wheel becomes loaded and dull with workpiece material, the wheel

should be cleaned with a dressing tool.

•

After reshaping, always readjust the tool rests and spark arrestors.

MAINTENANCE