Page of 14

8

STAND IN FRONT OF THE GRINDER. Stand to the side and allow the grinder to run for at

least one minute before proceeding to use it.

Installing or Changing the Wheel

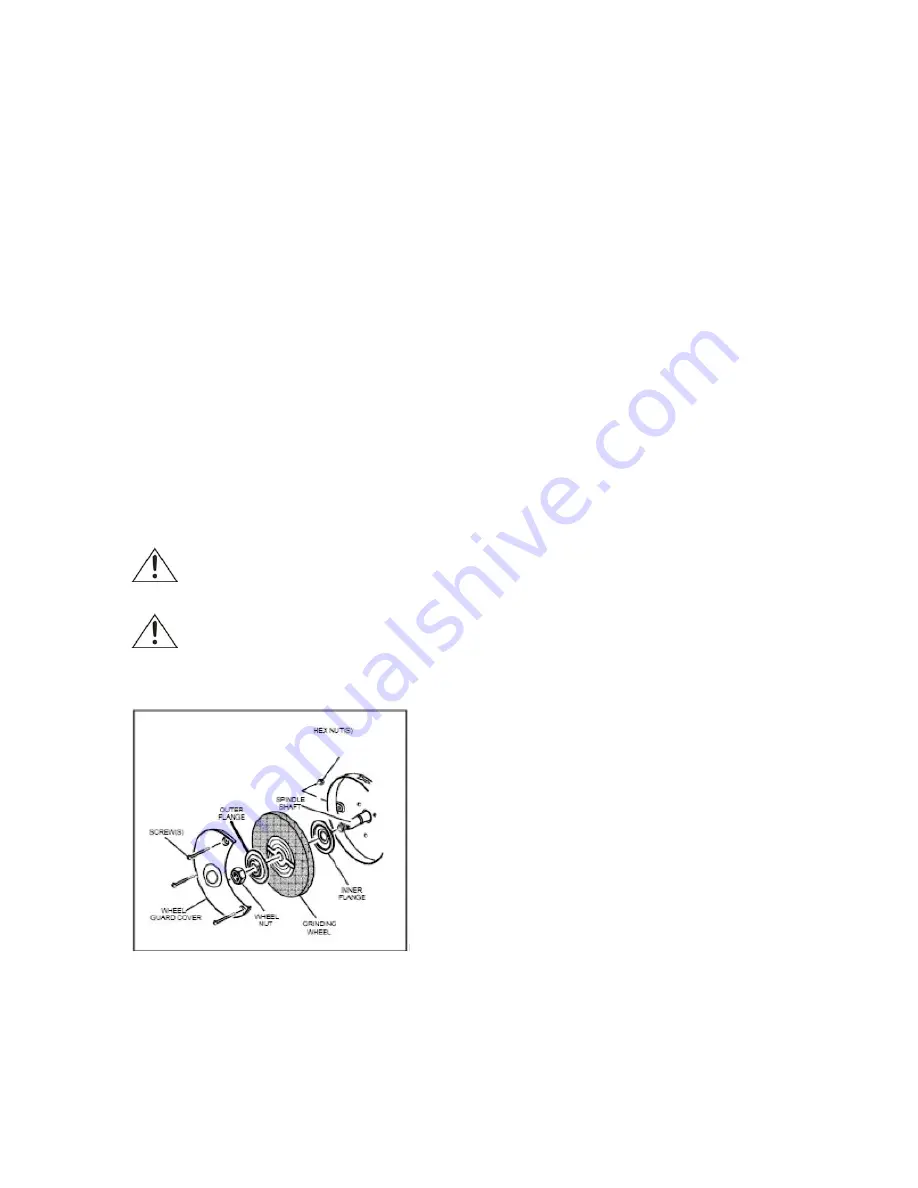

1. Loosen the tool rest hex nuts and slide the tool rest away from the wheel.

2. Use a screwdriver to remove the wheel-cover screws and remove the wheel cover.

3. Fit an appropriately sized wrench on the spindle hex nut.

4. Loosen the wheel nut in a clockwise direction for the left side and a counter-clockwise

direction for the right side.

5. Remove the outer flange and grinding wheel. To remove the hex nut, turn the wrench and

nut until the wrench is resting on the workbench behind the tool.

6. Inspect the new wheel carefully to ensure there are no cracks, chips or other damage.

7. Wipe the flange surfaces clean, and install the new wheel, flange and the spindle hex nut.

8. To install a new grinding wheel, reverse the above procedure.

9. Be sure the grinding wheel and outer flange are properly seated on the spindle shaft.

10. Replace the wheel cover and reposition the tool rest.

11. The tool rest, spark deflector and eye shields will need to be readjusted after installation of

the wheel is complete.

12.

When turning the grinder on with a newly installed wheel, DO NOT STAND IN FRONT

OF THE GRINDER. Stand to the side and allow the grinder to run for at least one

minute before proceeding to use it.

IMPORTANT! Do not overtighten the spindle hex nut, because this may cause the

wheel to crack.

CAUTION! DO NOT INSTALL OR USE A DAMAGED GRINDING WHEEL. The force of

rotation may cause a damaged wheel to fly apart, and could injure operators or bystanders.

Tool Rest Adjustments and Installation