26 SC2/CC3

32 SC2/CC3

- The remaining material is now automatically fed into

the cutting mechanism again and shredded.

- The control display

(6) goes out. The LED display

of the forwards button (3) is permanently lit.

- When the material has run through, continue

shredding with correct quantities.

- If necessary, operate the cutting mechanism manually

forwards and backwards alternately until the material

has completely run through and has been shredded.

Wait each time until the motor stops

before switching direction!

MOTOR PROTECTION:

If the motor is overloaded, it switches off. The control

display

(9) flashes. Switch the machine off with the

rocker switch (1).

After a cooling down period of approx. 25-40 minutes

(depending on the model and room temperature), you

can switch the machine on again.

MATERIAL JAM IN THE MACHINE:

(Auto-reverse function)

If a jam is caused by feeding in too much material, the

machine reacts as follows:

- The cutting mechanism is blocked, then runs briefly

in reverse (material is released) and stops. The

motor is switched off.

- The control display (6) lights up.

Proceed as follows:

Paper jam in paper feed slot (12)

- Remove released paper from the feed slot (12).

- Cutting mechanism now runs forwards automatically

and shreds the remaining paper in the cutting

mechanism.

- The control display

(6) goes out. The LED display

of the forwards button (3) is permanently lit.

- Continue shredding with lower quantity of paper.

Material jam in safety feed slot (13)

- Remove released material.

Take care when removing material as

sharp edges may cause injury!

CHECkLIST IN THE EVENT OF FAULTS:

If the machine does not work, check the following

points:

- is the

mains plug

connected to the mains?

- is the machine in

“Sleep” mode

?

See “AUTOMATIC ENERGY SAVING”.

- has the

user interlock

been activated?

See “OPERATION OF THE USER INTERLOCK”.

- is the

receptacle

pushed in?

- is the

receptacle

full?

Follow the instructions in “EMPTYING THE

RECEPTACLE”.

- is there a

material jam

in the machine?

Follow the instructions in “MATERIAL JAM IN THE

MACHINE”.

- Has the motor been overloaded?

See “MOTOR PROTECTION”.

If none of the above applies, please contact your

dealer.

16

89894 9 12/13

7

GB

MAINTENANCE OF THE

CUTTING MECHANISM (CROSS-CUT):

Cross-cut cutting mechanisms must be oiled

after a certain operating time.

If the control display

(7) lights up, proceed

as follows:

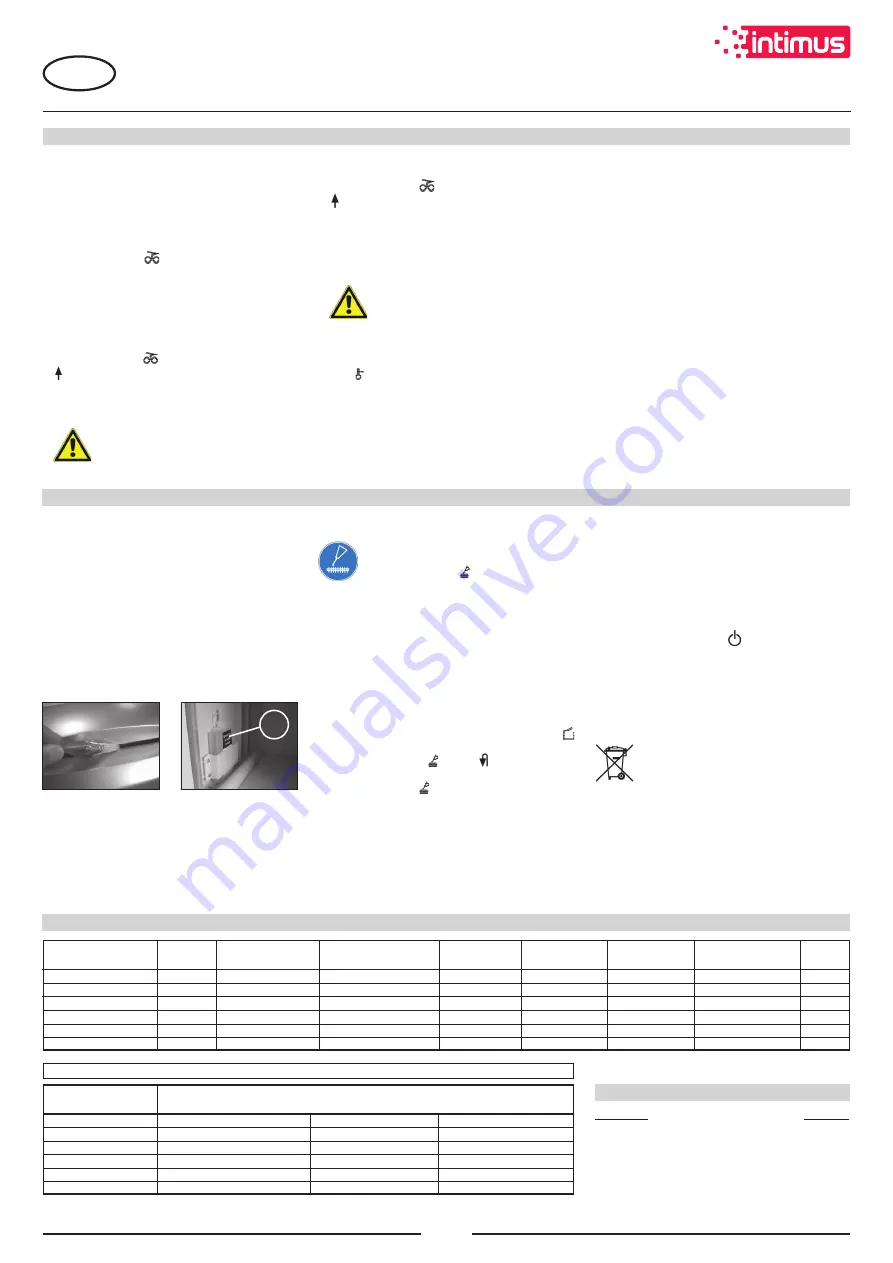

Pull out receptacle (14), take oil receptacle (16) (Fig.

6) out of the holder in the lower cabinet and push

receptacle in again.

Spread some oil on a sheet of paper and then feed

it into the cutting mechanism through the paper feed

slot (12).

The paper is drawn in and the oil thus gets into the

cutting mechanism.

Note: The oiling procedure needs to be confirmed as

follows to delete the control display:

- Pull out receptacle (14) until the control display

(8) lights up.

- The control displays (7) and

(4) flash.

- Press backwards button (4) and keep pressed until

the control display (7) goes out.

- Push receptacle in again.

CLEANING THE PHOTOCELLS (Fig. 5):

If paper particles should come to rest in the inlet

guide (for example after a paper jam) it is possible

that the machine will not turn off, due to the broken

light barrier.

To remove these paper strips and also to clean the

photocell, pass another sheet of paper through the

feed slot, or switch the machine to reverse and wipe

both “eyes” of the photocell with a brush.

The cutting mechanism now automatically begins

the cleaning cycle (forwards operation/backwards

operation) and then switches off. The machine is

ready again. To re-order the special oil, see “SPECIAL

ACCESSORIES”.

AUTOMATIC ENERGY-SAVING:

If the machine is not used for a while, it automatically

switches to the so-called “Sleep” mode after approx.

30 mins. The LED display

of the function button

(2) for “Ready” goes out. To switch on again, briefly

press the function button. If the user interlock is

switched on, it must be deactivated again when the

machine is switched on again (see “

operating the

machine

”).

DISPOSING OF THE MACHINE:

Dispose of the machine in an environmentally

friendly fashion at the end of its useful service

life. Do not dispose of any of the parts

included in the machine or its packaging with

household waste.

MAINTENANCE / DISPOSING

MALFUNCTIONS

*

based on A4-paper 70g/m² at 230V/50Hz – 10%

TECHNICAL DATA

SPECIAL ACCESSORIES

Description

Order-No.

Plastic bag, 300x300x700x0.018 mm

99925

Lubricant, 110 ml bottle

88035

Note:

For orders of special accessories and spare parts,

please contact your dealer.

fig. 5

fig. 6

Translation of the Original Operation Manual

Übersetzung der Originalbetriebsanleitung

pre-fusing

(slow-blow)

:

220-240V = 10 amps / 120V = 15 amps

Model

Typ

Cutting width

Cutting capacity

Working width

Noise level

Intermittent operation

Dimensions

Weight

paper / CD,DVD

paper / CD,DVD

ON / OFF

W x D x H

intimus 26SC2

276-4S

4 mm / 8 mm

13 sheets* / 1 piece

240 mm

app. 55 dB(A)

10 / 45 min

390 x 330 x 550 mm

16 kg

intimus 26CC3

276-4C

4x28 mm / 8 mm

9 sheets* / 1 piece

240 mm

app. 55 dB(A)

10 / 45 min

390 x 330 x 550 mm 16.2 kg

intimus 32SC2

277-4S

4 mm / 8 mm

17 sheets* / 1 piece

240 mm

app. 55 dB(A)

10 / 45 min

390 x 360 x 600 mm 16.5 kg

intimus 32CC3

277-4C

4x28 mm / 8 mm

12 sheets* / 1 piece

240 mm

app. 55 dB(A)

10 / 45 min

390 x 360 x 600 mm 16.7 kg

Model

Power supply data

supply voltage/frequency · current consumption · power

intimus 26SC2

220-240V/50Hz · 1.7 amps · 0.39 kW 120V/60Hz · 2.9 amps · 0.35 kW

intimus 26CC3

220-240V/50Hz · 1.7 amps · 0.39 kW 120V/60Hz · 2.9 amps · 0.35 kW

intimus 32SC2

220-240V/50Hz · 1.9 amps · 0.44 kW 120V/60Hz · 3.5 amps · 0.42 kW

intimus 32CC3

220-240V/50Hz · 1.9 amps · 0.44 kW 120V/60Hz · 3.5 amps · 0.42 kW