Summit Series

®

II

User’s Manual

SCALABLE PROFILE

: The nominal DC voltage of the “Active Battery Profile” is automatically scaled

to 48V, 36V, or 24V based on the connected battery pack.

NOTE: If the charger is currently set to

“Per Voltage Profiles” or “Scalable Profile” mode, and you set

the “Auto Profile” selection box to “Off”, you MUST ensure that the nominal DC voltage of the “Active

Battery Profile

” for the charger matches the nominal DC voltage of the connected battery pack via the

“Battery Profiles” screen in the ChargerConnect app.

When Auto Voltage Mode is active (either “Per Voltage Profiles” or “Scalable Profile”) the ChargerConnect

app “Dashboard” screen provides the status of the proprietary algorithm that execute

s at the beginning of the

charge cycle by displaying the “Auto Battery Voltage Detection” as a status percentage and the “Detected

Battery Pack Voltage”.

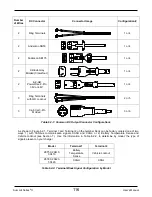

6.2 DC Output Cordset

The DC output cordset includes a connector, plug, or terminals. The polarity of the charger DC

connector/plug/terminals must be the same as the battery connector/receptacle/terminals. The BLACK DC

cable must be connected to the battery negative (-), and the WHITE or RED DC cable must be connected to

the battery positive (+). The charger will not operate if the polarity is reversed.

WARNING: CHARGER DC CORDSET MUST HAVE A MINIMUM OF 12AWG WIRE SIZE FOR

PROPER HEAT DISSIPATION. TO PREVENT RISK OF FIRE, DO NOT USE SMALLER GAUGE WIRE.

The DC cordset attaches to the external DC terminal block on the charger. Remove the touch proof cover (if

pre-installed) to expose the DC terminal block as shown in Figure 6.2-1. Based on the DC cordset

connector/plug/terminals, use Table 6.2-1 to determine the correct Configuration Number, and then attach the

DC cordset wires as shown in Figure 6.2-2. Torque the screws for the Battery Positive and Battery Negative

connections to 18 in-lbs (2.0 N-m). Torque the screws for Terminal 1 (Battery Temperature Sense or CANH)

and Terminal 2 (Vehicle Lockout or CANL) connections to 12 in-lbs (1.35 N-m). Place the strain relief over

the DC cordset cable/wires. When individual wires are used for on-board applications, place the foam rubber

gasket that comes on the cordset under the strain relief, center the wires, and then tighten the strain relief

screws and torque them to 9 in-lbs (1 N-m). This prevents the wires from getting pinched on the side of the

strain relief when tightened. Replace the terminal block cover, and torque the cover screws to 9 in-lbs (1 N-

m). The terminal block cover is reversible, so either strain relief can be used.

Figure 6.2-1: DC Terminal Block

Battery Positive, (+)

Battery Negative, (-)

Cord Strain Relief

Terminal 1, Battery

Temp Sense or CANH

Terminal 2, Vehicle

Lockout or CANL

Cord Strain Relief

115

Summary of Contents for eNVy neighborhood vehicle

Page 1: ...OWNER S MANUAL 1 ...

Page 58: ...Service Record Number Date Hour Meter Reading Dealer Stamp 1 2 3 4 5 6 7 8 58 ...

Page 61: ...Golf Cart Battery Install Maintenance 61 ...

Page 71: ...OCV Open Circuit Voltage vs SOC State of Charge 71 ...

Page 92: ...92 ...

Page 94: ...94 ...

Page 96: ...96 ...

Page 128: ...Summit Series II User s Manual Represented By 43068 B 128 ...