8

441 01 1411 04

Specifications are subject to change without notice.

Table 3 – Minimum Space volumes for 100% combustion, Ventilation, and Dilution from Indoors

ACH

OTHER THAN FAN

−

ASSISTED TOTAL

(1,000’S BTUH GAS INPUT RATE

FAN

−

ASSISTED TOTAL

(1,000’S BTUH GAS INPUT RATE)

30

40

50

44

66

88

110

132

Space Volume (ft.

3

)

0.60

1,050

1,400

1,750

1,100

1,650

2,200

2,750

3,300

0.50

1,260

1,680

2,100

1,320

1,980

2,640

3,300

3,960

0.40

1,575

2,100

2,625

1,650

2,475

3,300

4,125

4,950

0.30

2,100

2,800

3,500

2,200

3,300

4,400

5,500

6,600

0.20

3,150

4,200

5,250

3,300

4,950

6,600

8,250

9,900

0.10

6,300

8,400

10,500

6,600

9,900

13,200

16,500

19,800

0.00

NP

NP

NP

NP

NP

NP

NP

NP

ACH = Air Changes/Hour

NP = Not Permitted

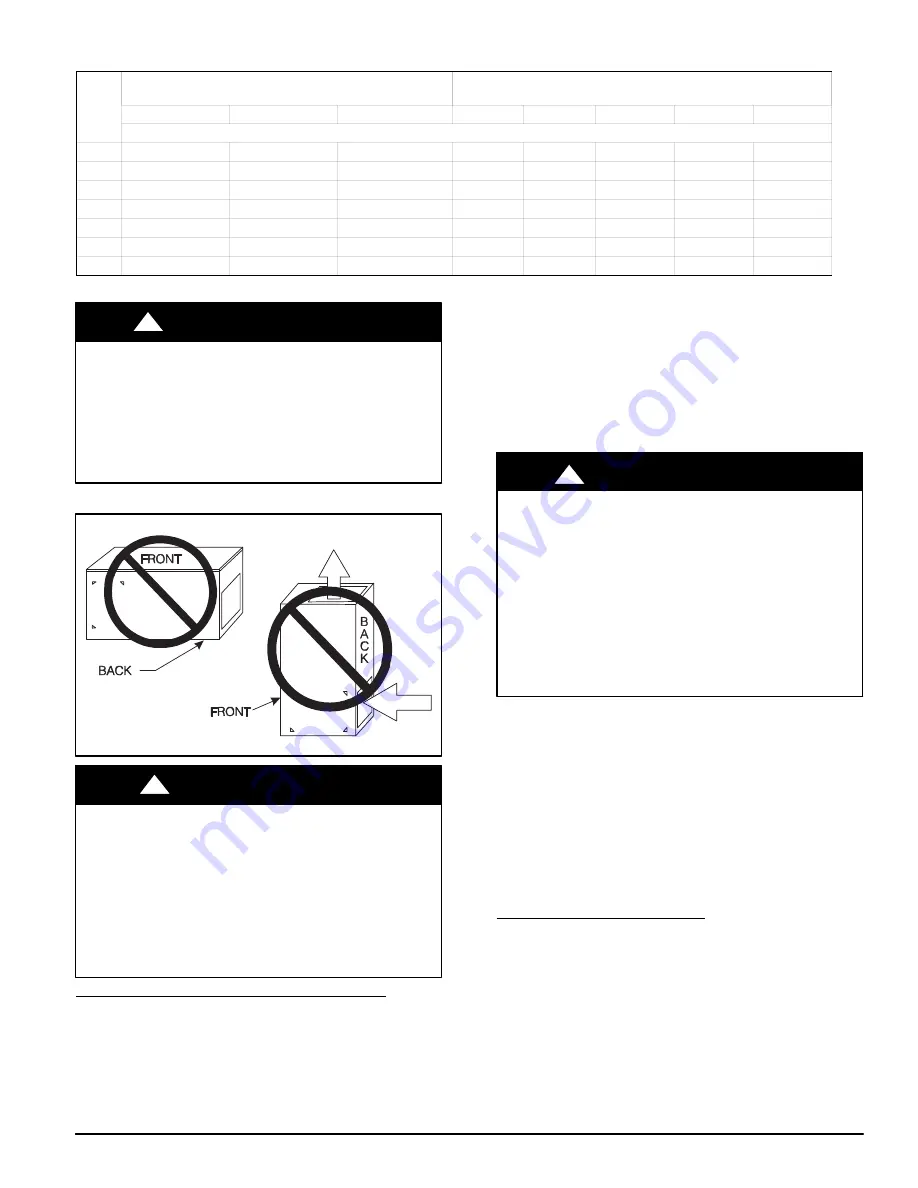

FIRE HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Do not install the furnace on its back or hang furnace

with control compartment facing downward. Safety

control operation will be adversely affected. Never

connect return

−

air ducts to the back of the furnace.

(See Figure 6)

!

WARNING

Figure 6

−

Prohibit Installation on Back

A02054

FURNACE CORROSION HAZARD

Failure to follow this caution may result in furnace

damage.

Air for combustion must not be contaminated by

halogen compounds, which include fluoride, chloride,

bromide, and iodide. These elements can corrode

heat exchangers and shorten furnace life. Air

contaminants are found in aerosol sprays,

detergents, bleaches, cleaning solvents, salts, air

fresheners, and other household products.

CAUTION

!

LOCATION RELATIVE TO COOLING EQUIPMENT

The cooling coil must be installed parallel with, or on the

downstream side of the unit to avoid condensation in the heat

exchangers. When installed parallel with the furnace,

dampers or other flow control must prevent chilled air from

entering the furnace. If the dampers are manually operated,

they must be equipped with means to prevent operation of

either unit unless the damper is in the full

−

heat or full

−

cool

position.

AIR FOR COMBUSTION AND

VENTILATION

Provisions for adequate combustion, ventilation, and dilution

air must be provided in accordance with:

S

U.S. installations: Section 9.3 of the NFGC

NFPA54/ANSI Z223.1

−

2012, Air for Combustion and

Ventilation, and applicable provisions of the local

building codes.

!

WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal

injury or death.

The operation of exhaust fans, kitchen ventilation

fans, clothes dryers, attic exhaust fans or fireplaces

could create a NEGATIVE PRESSURE CONDITION

at the furnace. Make

−

up air MUST be provided for the

ventilation devices, in addition to that required by the

furnace. Refer to Carbon Monoxide Poisoning Hazard

warning in venting section of these instructions to

determine if an adequate amount of make

−

up air is

available.

The requirements for combustion and ventilation air depend

upon whether or not the furnace is located in a space having

a volume of at least 50 cubic feet per 1,000 Btuh input rating

for all gas appliances installed in the space.

S

Spaces having less than 50 cubic feet per 1,000

Btuh require the

OUTDOOR COMBUSTION AIR

METHOD.

S

Spaces having at least 50 cubic feet per 1,000 Btuh

may use the

INDOOR COMBUSTION AIR,

STANDARD or KNOWN AIR INFILTRATION

METHOD.

Outdoor Combustion Air Method

1. Provide the space with sufficient air for proper combus-

tion, ventilation, and dilution of flue gases using per-

manent horizontal or vertical duct(s) or opening(s) dir-

ectly communicating with the outdoors or spaces that

freely communicate with the outdoors.

2. Figure 7 illustrates how to provide TWO OUTDOOR

OPENINGS, one inlet and one outlet combustion and

ventilation air opening, to the outdoors.

a. One opening

MUST

commence within 12

−

in. (300

mm) of the ceiling and the second opening

MUST

commence within 12

−

in. (300 mm) of the floor.

b. Size openings and ducts per Figure 7 and Table 2.