44

Intermec EasyCoder PD4—Service Manual

Chapter 7—Print Mechanism

4

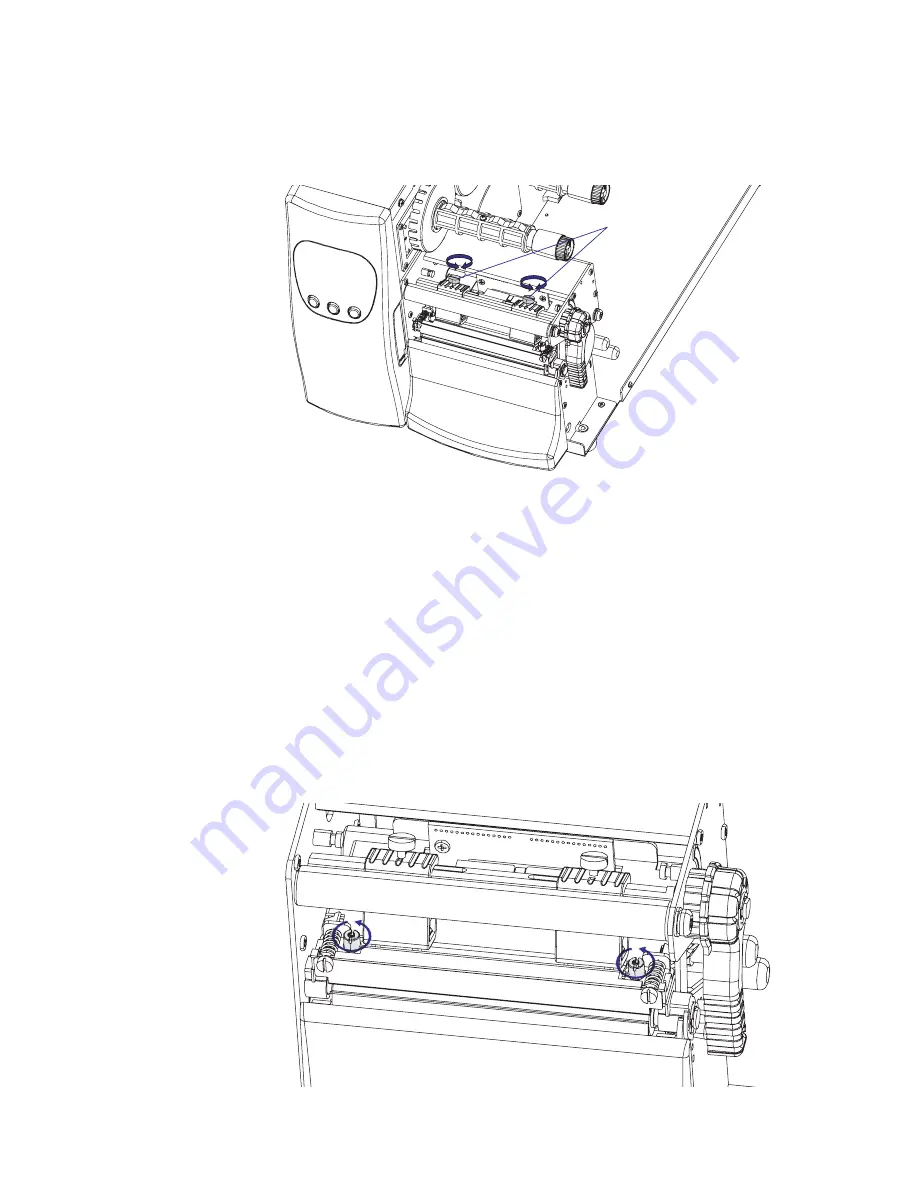

Use a straight-slot screwdriver to turn the screw at the top of the balance

boxes clockwise to increase the pressure or counterclockwise to decrease

the pressure. To set the pressure to factory default value, turn the screws

down completely and then 9 turns up (counterclockwise).

5

Engage the printhead and load the ribbon.

6

Test and readjust if necessary. (Hint! If you use direct thermal media you

will not have to load and remove the ribbon over and over again.)

Printhead Dot Line Position

When using thick or stiff media, the printhead needs to be moved forward

so the dot line becomes exactly aligned with the top of the platen roller.

Obviously, the platen roller and printhead must also be completely in

parallel.

To perform this adjustment, follow

all

the steps below:

1

Open the top cover.

2

Remove the ribbon.

3

Important step!

Use a straight-slot screwdriver to turn the two screws at

the top of the printhead bracket counterclockwise a single turn.

Adjustment screws

Summary of Contents for EasyCoder PD4

Page 1: ...Service Manual EasyCoder PD4 Bar Code Label Printer ...

Page 4: ...iv Intermec EasyCoder PD4 Service Manual ...

Page 24: ...14 Intermec EasyCoder PD4 Service Manual Chapter 2 Front Panels ...

Page 36: ...26 Intermec EasyCoder PD4 Service Manual Chapter 5 Media Supply ...

Page 58: ...48 Intermec EasyCoder PD4 Service Manual Chapter 7 Print Mechanism ...

Page 66: ...56 Intermec EasyCoder PD4 Service Manual Chapter 9 Strip Module ...

Page 72: ...62 Intermec EasyCoder PD4 Service Manual Chapter 10 Cutter ...

Page 94: ...84 Intermec EasyCoder PD4 Service Manual Chapter 12 Main Board ...

Page 110: ...100 Intermec EasyCoder PD4 Service Manual Chapter 14 Troubleshooting ...

Page 113: ......