Intermec EasyCoder 501 E – Installation & Operation Ed. 1

106

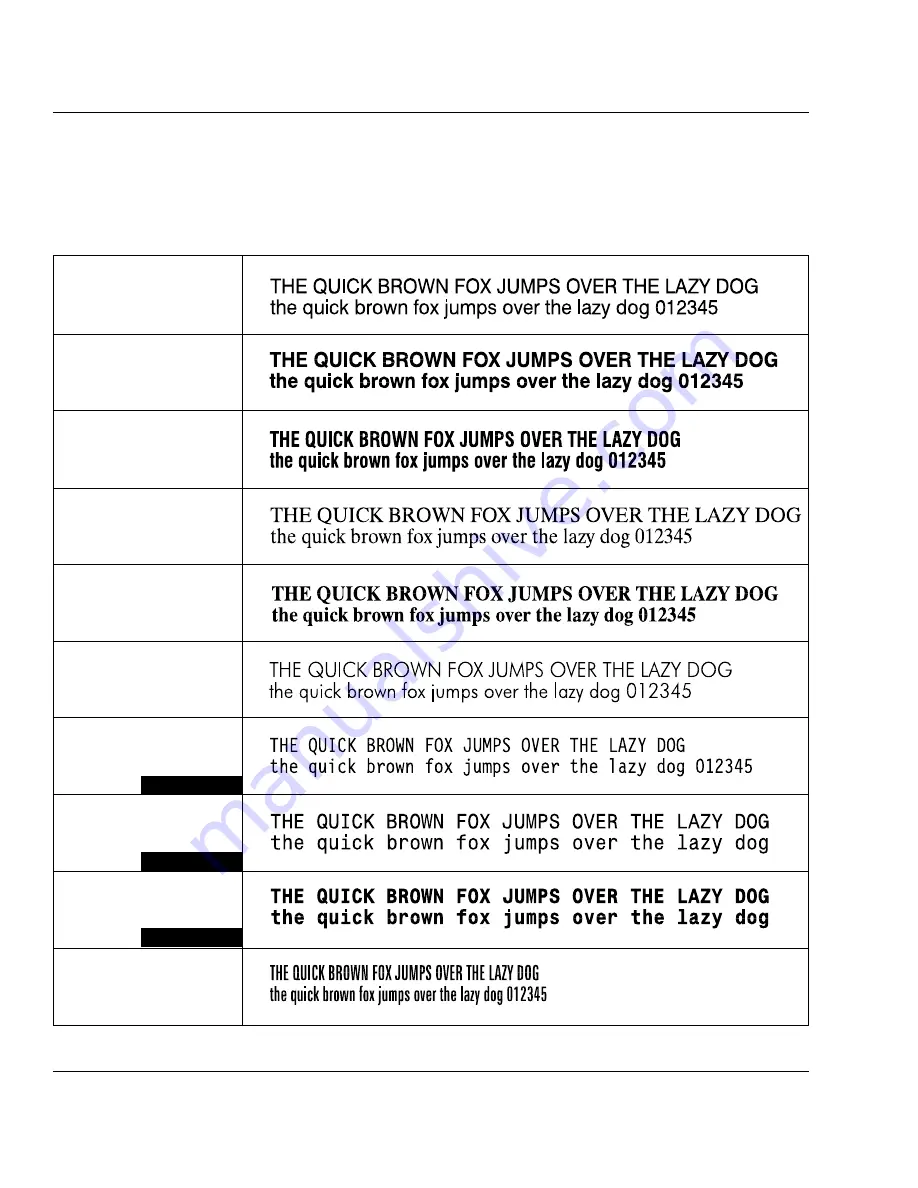

Chapter 10 Options

Intermec0003.SPD

Bitstream Swiss 721

0003 Roman

Intermec0005.SPD

Bitstream Swiss 721

0005 Bold

Intermec0010.SPD

Bitstream Swiss 721

0010 Bold Condensed

Intermec0011.SPD

Bitstream Dutch 801

0011 Roman

Intermec0013.SPD

Bitstream Dutch 801

0013 Bold

Intermec0138.SPD

Bitstream Futura

0138 Light

Intermec0414.SPD

Bitstream Letter Gothic 12 Pitch

0414 Roman

Intermec0596.SPD

Bitstream Monospace 821

0596 Roman

Intermec0598.SPD

Bitstream Monospace 821

0598 Bold

Intermec0959.SPD

Bitstream Zurich

0959 Extra Condensed

Scaleable Fonts

Kit, cont.

Printout Samples

The following 10 scaleable outline fonts in Speedo format are

stored in the EPROMs of the Scaleable Fonts Kit. All characters

from ASCII 32 through 254 decimal according to the Roman 8

character set are included.

Fixed Spacing

Fixed Spacing

Fixed Spacing