HelvC

NugFont

C

39

Using Test and Service Mode

6-7

6

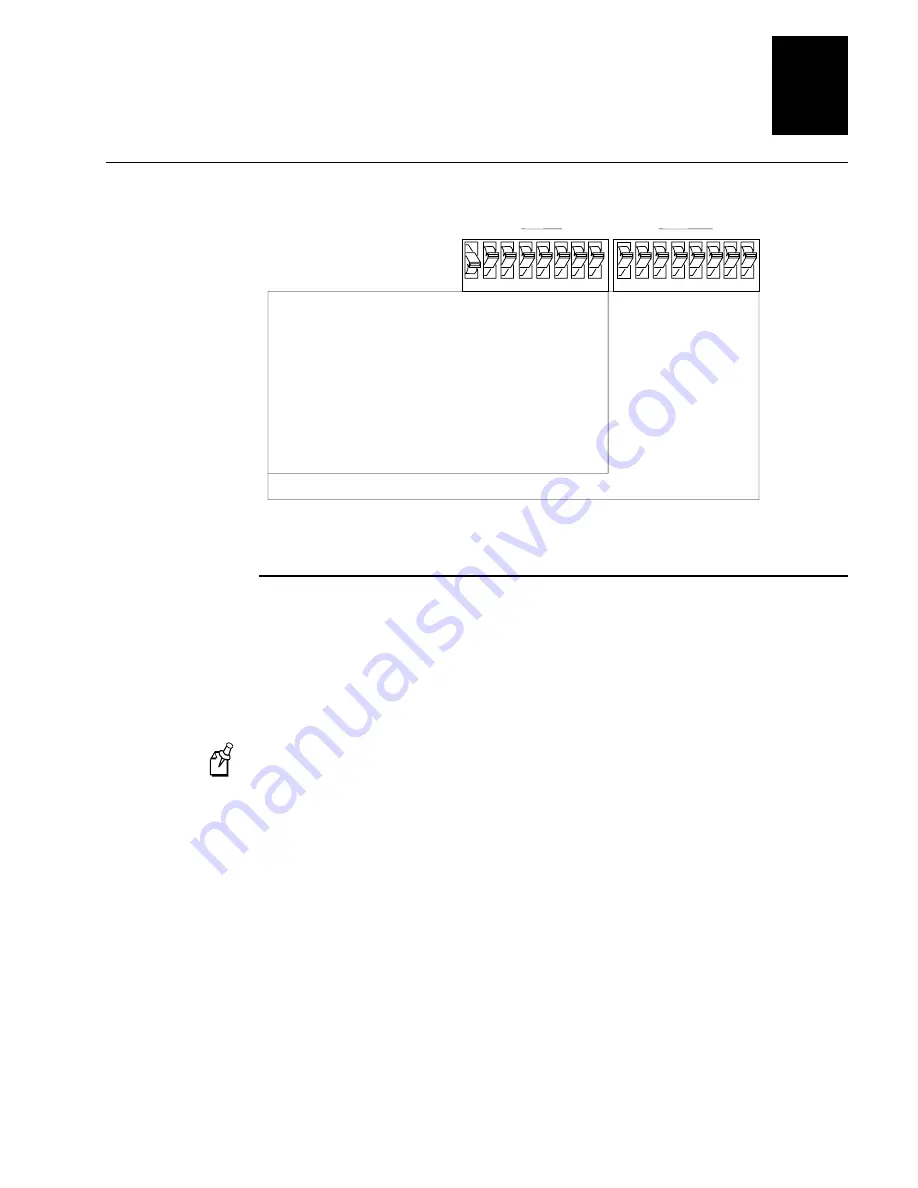

Configuration DIP Switch Settings

3XXXU.046

1 2 3 4 5 6 7 8

Label Rest Point

Adjust Forward

Adjust Backward

86XX Emulation

Advance Mode

10 Mil

15 Mil

X Forms Adjust

Adjust Forward

Adjust Backward

Y Forms Adjust

O

1

1

1

1

O

1

1

1

1

1

1

O

1

O

1

1

1

O

O

O

1

O

1

Top Bank

1 2 3 4 5 6 7 8

Bottom Bank

O = OFF

1 = ON

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

ON

OFF

N: Number. Least significant bit first.

Setting the Number of Dot Increments

You can move the label rest point and X forms adjust configuration commands forward

or backward by setting the printer DIP switches. Use the top bank of DIP switches to

determine whether the movement is forward or backward. Use the bottom bank of DIP

switches to set the number of dot increments for label rest point, X forms adjust, and Y

forms adjust. The printer moves in 5 mil increments or 0.005 inch per dot.

Note: The next table only shows the settings for the bottom bank of switches, see the

Configuration DIP Switch Settings table for the top bank DIP switch settings.

Summary of Contents for EasyCoder 3400e

Page 1: ...EasyCoder 3400e BarCodeLabelPrinter P N 071881 001 User s Manual ...

Page 8: ...asdf ...

Page 14: ...asdf ...

Page 15: ...Getting Started 1 ...

Page 16: ...asdf ...

Page 33: ...Operating the Printer 2 ...

Page 34: ...asdf ...

Page 50: ...adf ...

Page 51: ...Maintaining the Printer 3 ...

Page 52: ...asdf ...

Page 62: ...NugFont C 39 asdf ...

Page 63: ...Troubleshooting 4 ...

Page 64: ...asdf ...

Page 71: ...Optimizing Printer Performance 5 ...

Page 72: ...asdf ...

Page 81: ...Using Test and Service Mode 6 ...

Page 82: ...asdf ...

Page 95: ...Specifications A ...

Page 96: ...asdf ...

Page 105: ...Character Sets B ...

Page 106: ...asdf ...

Page 114: ...asdf ...

Page 115: ...Communications Reference C ...

Page 116: ...asdf ...

Page 126: ...HelvC NugFont C 39 asdf ...

Page 127: ...Full ASCII Table D ...

Page 128: ...asdf ...

Page 132: ...asdf ...

Page 133: ...Glossary G ...

Page 134: ...asdf ...

Page 142: ...asdf ...

Page 143: ...Index I ...

Page 144: ...asdf ...

Page 150: ...asdf ...