X.

AUXILIARY MODE

AUXILIARY TRIM PROGRAMMING:

The

Auxiliary

input is used in the Follower mode to change the relationship between

the Master and Follower motor speeds, based on the input of a third frequency. This

frequency is commonly generated with Drive Control System’s AIFO-200 (analog-to-

frequency converter). The input to the AIFO-200 can be generated by a dancer pot, a

pressure transducer, or any other device with a 0-10V or 4-20mA output.

In Auxiliary Trim mode, the

Auxiliary Frequency

input trims the final Follower motor

speed by adding or subtracting Auxiliary pulses to the Lead frequency, making the

Follower motor increase or decrease speed. The speed change is determined by the

following formula:

(Var 25) (Var 26)

Aux Freq Input Hz

-

1/2 Aux Ref Freq

(Var 01)

x Aux Gain x

Max Feedback

1/2 Aux Ref Freq

(Var 25)

Multiply the Result by -1 if Var 27 is 0

The Auxiliary error count from this formula is summed in every .02 seconds as long as

the lead motor is running. When the lead motor stops, the error count is returned to zero.

There are provisions for adding a delay on start-up, adjusting the amount of authority or

gain of the Auxiliary input, polarity change (increasing frequency decreases speed or

increasing frequency increases speed), and the frequency input programming.

Variable 24- Auxiliary Mode Selection

- 0000 -Auxiliary Input is disabled. 000l-

Auxiliary Trim mode is active.

Variable 25- Auxiliary Reference Frequency

-

Enter the maximum frequency of

the auxiliary input. Zero trim correction is 50% of the programmed frequency; 9,999 Hz

maximum.

Variable 26- Auxiliary Gain Percentage -

This value is the percentage of maximum

speed (Variable 01) that can be corrected by the Auxiliary Trim mode. Enter 0 to 999%.

Variable 27- Auxiliary Trim Selection

-

Entering 0000: Increasing the frequency

above 50% of the auxiliary reference frequency will decrease motor speed. Decreasing

the frequency will increase motor speed. Entering 0001

:

Increasing the frequency above

50% of the auxiliary reference frequency will increase motor speed. Decreasing the

frequency will decrease motor speed.

Variable 28 - Auxiliary Input Delay

-

Delays the start of the Auxiliary Trim

function on startup. Enter the number of 10 msec update cycles to wait. When

ENTER

is pressed, the MicroSpeed 196 will insert a decimal point to display the delay in

seconds.

21

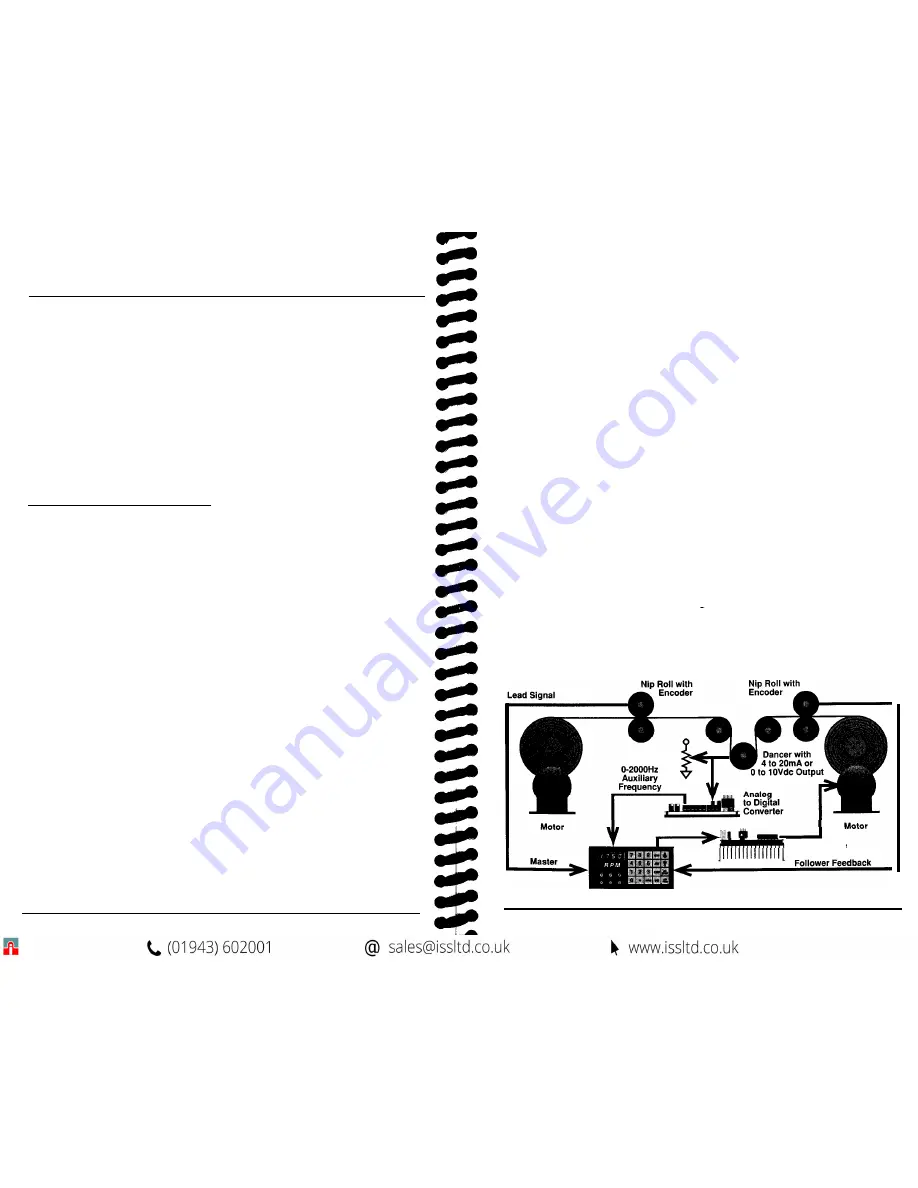

EXAMPLE:

In this application, (see Diagram 7, below) the MicroSpeed 196 is programmed to

control the wind-up (Follower) motor in a one-to-one relationship with the unwind

(Master) motor. Tension is controlled by a dancer arm. We will use 1000 rpm on the

encoders as the maximum speed of both the unwind (Master) and wind up (Follower)

reels. This would be entered into Variable 04

(Maximum Lead RPM)

and Variable 01

(Maximum RPM).

We will assume a 12-inch circumference on the nip rolls. Because

of this, we can enter 1000 into Variable 02

(User Units at Max RPM)

and the tach

will display ft/min. The PPR of the encoders is entered into Variable 03

(Feedback

PPR)

and Variable 05

(Lead PPR).

Enter the Ratio Set Point 1.000. The MicroSpeed

196 is now programmed to run in a one-to-one Master/Slave relationship. The machines

should now be operated, and PID tuning is completed.

The AIFO-200 has been programmed to provide a 0 - 2000 Hz output, based on a 0 -

10V input signal from the dancer. 2000 is entered into Variable 25

(Auxiliary

Reference Frequency).

The MicroSpeed 196 will add correction whenever the

Auxiliary Reference frequency

is not l/2 value. Set Variable 26

(Auxiliary Gain

Percentage)

at 10% to start with, and change Variable 24

(Auxiliary Mode

Selection)

to 1, to enable the input as a trim function. Variable 27

(Auxiliary Trim

Selection)

will be set to 0. This gives a decrease in Follower motor speed, with an

increase in input frequency from the AIFO.

After starting the machine with the

Auxiliary

input active, (Variable 26)

Auxiliary

Gain Percentage

can be adjusted. Higher percentages result in tighter control;

however percentages that are too high will cause instability. It may also be desirable to

delay the Auxiliary trim on a start command. This allows the motors to get up to speed,

or above the low torque range, before adding extra correction changes. Use Variable 28

(Auxiliary Delay)

for this function.

Diagram 7

Typical Auxiliary Trim Mode Application:

AIFO -

200

AC or DC Drive

MicroSpeed 196

22

Summary of Contents for MicroSpeed 196

Page 1: ...MSMAN32C MicroSpeed 196...

Page 19: ......