21

3.

Locate the CMOS clear jumper on the motherboard.

4.

Move the jumper cap from the default pins 1-2 to pins 2-3.

5.

Plug in the power cable and power on the server, and then wait for 10 seconds for

the CMOS to clear.

6.

Power down the server, unplug the power cable, and then wait for 5 seconds

again.

7.

Move the jumper cap back to the default pins 1-2.

8.

Reconnect the power cable and power on the server.

3.5

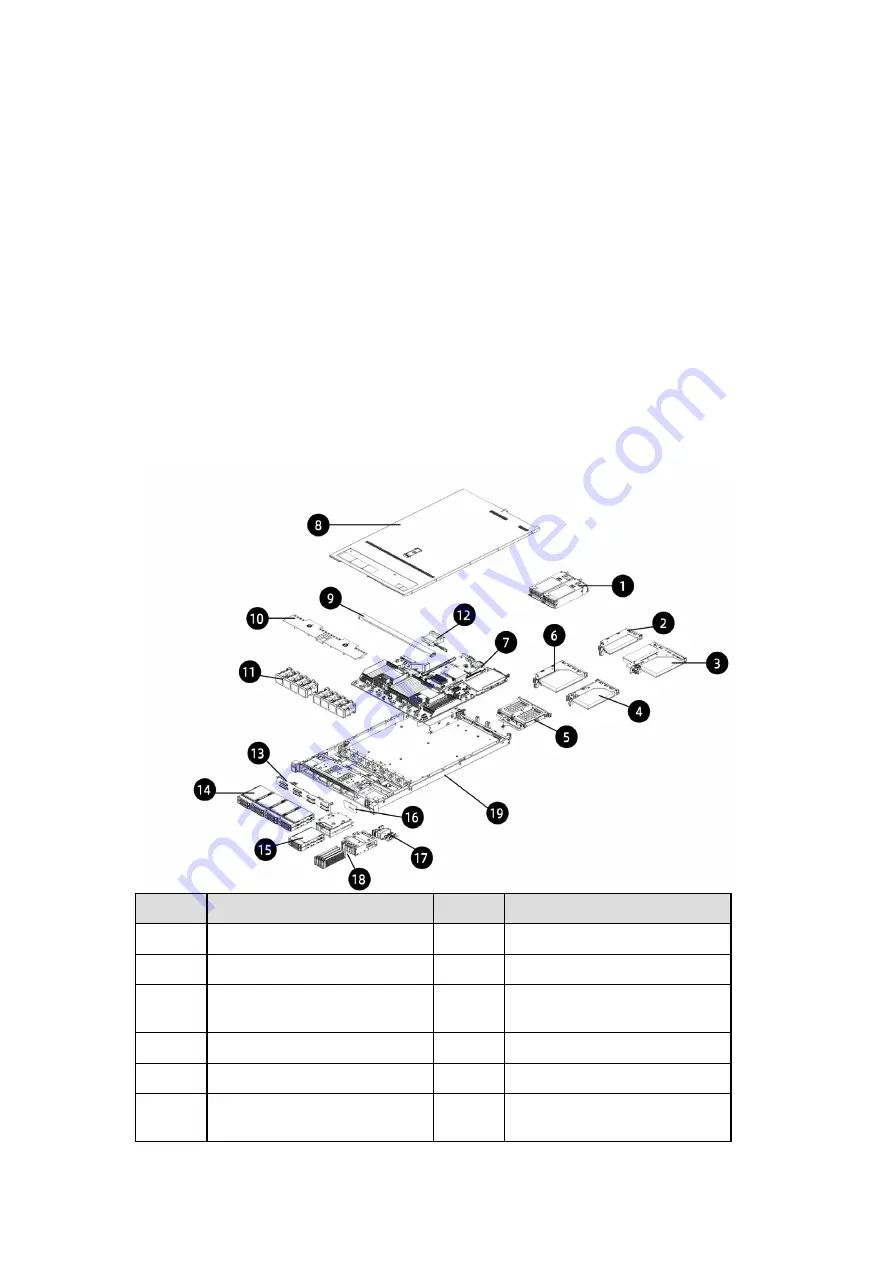

System Layout

The layouts of systems with 2.5-inch and 3.5-inch drives are as below:

Figure 3-13 System Layout with 2.5-inch Drives

#

Item

#

Item

1

PSUs

11

Fan Module

2

LP PCIe

12

Super-Capacitor

3

Butterfly PCIe

13

Front 2.5-inch Drive

Backplane

4

Right PCIe Module

14

Front 2.5-inch Drive Module

5

Rear 2.5-inch Drive Module

15

Front 2.5-inch Drive Module

6

Left PCIe Module

16

Front 2.5-inch Drive

Backplane