21

WARNING: UNPLUG POWER CORD BEFORE MAINTENANCE.

WARNING: STOP TREADMILL BEFORE FOLDING.

AFTER EACH USE

After each use, clean and inspect, following these steps:

1) Turn off the treadmill with the on/off switch, and then unplug the power cord at the wall outlet.

2) Wipe down the running belt, deck, motor cover, and console casing with a damp cloth. Never

use solvents, as they can cause damage to the treadmill.

3) Inspect the power cord.

4) Make sure the power cord is not underneath the treadmill or in any other area where it can

become pinched or cut.

5) Check the tension and alignment of the running belt. Make sure that the treadmill belt will not

damage any other components on the treadmill by being misaligned.

GENERAL CLEANING

1) Use a soft, damp cloth to wipe the edge of the belt and the area between the belt edge and

frame. A mild soap and water solution along with a nylon scrub brush will clean the top of the

textured belt. This task should be done once a month. Allow to dry before using.

2) On a monthly basis, vacuum underneath your treadmill to prevent dust build up. Once a year,

you should remove the black motor shield and vacuum out dirt that may accumulate.

GENERAL CARE

1) Check parts for wear before use.

2) Pay particular attention to the fixing knobs and make sure they are tight.

3) Always replace the mat if worn and any other defective parts.

4) If in doubt do not use the treadmill and contact our helpline.

TAKE CARE TO PROTECT CARPETS AND FLOOR in case of leakages. This product is a machine

that contains moving parts which have been greased / lubricated and could leak.

IDENTIFICATION WAYS FOR THE DEGREE OF TIGHTNESS OF RUNNING BELT

AND MOTOR BELT

When the running belt skips, please follow the steps as follows to make sure which belt needs to be

adjusted, running belt or motor belt.

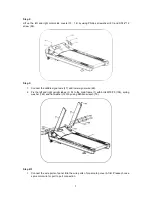

a) Cut off power, screw off the bolt on cover of protection. Then take down the protecting cover

from the treadmill

b) Turn the speed to be around 3kph, step on the running belt by pressure and try your best to

make the running belt stop. If running belt stops, together with the front roll, but the motor still

runs, under this condition, it means the motor belt needs to be adjusted.

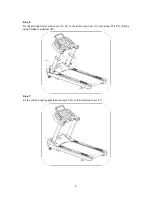

CENTERING THE RUNNING BELT

DO NOT OVERTIGHTEN THE RUNNING BELT.

This may cause reduced motor performance and

excessive roller wear.