17

10.2 Connection to Water Source

Make sure that the inlet valve is installed as shown in the diagram before

making the water connection. It should be possible to close this inlet valve

for malfunction and maintenance.

Make sure the water temperature and circuit water pressure is in

compliance with the machine’s label values.

If the water pressure is insufficient, install a pressure increasing pump.

Image 7

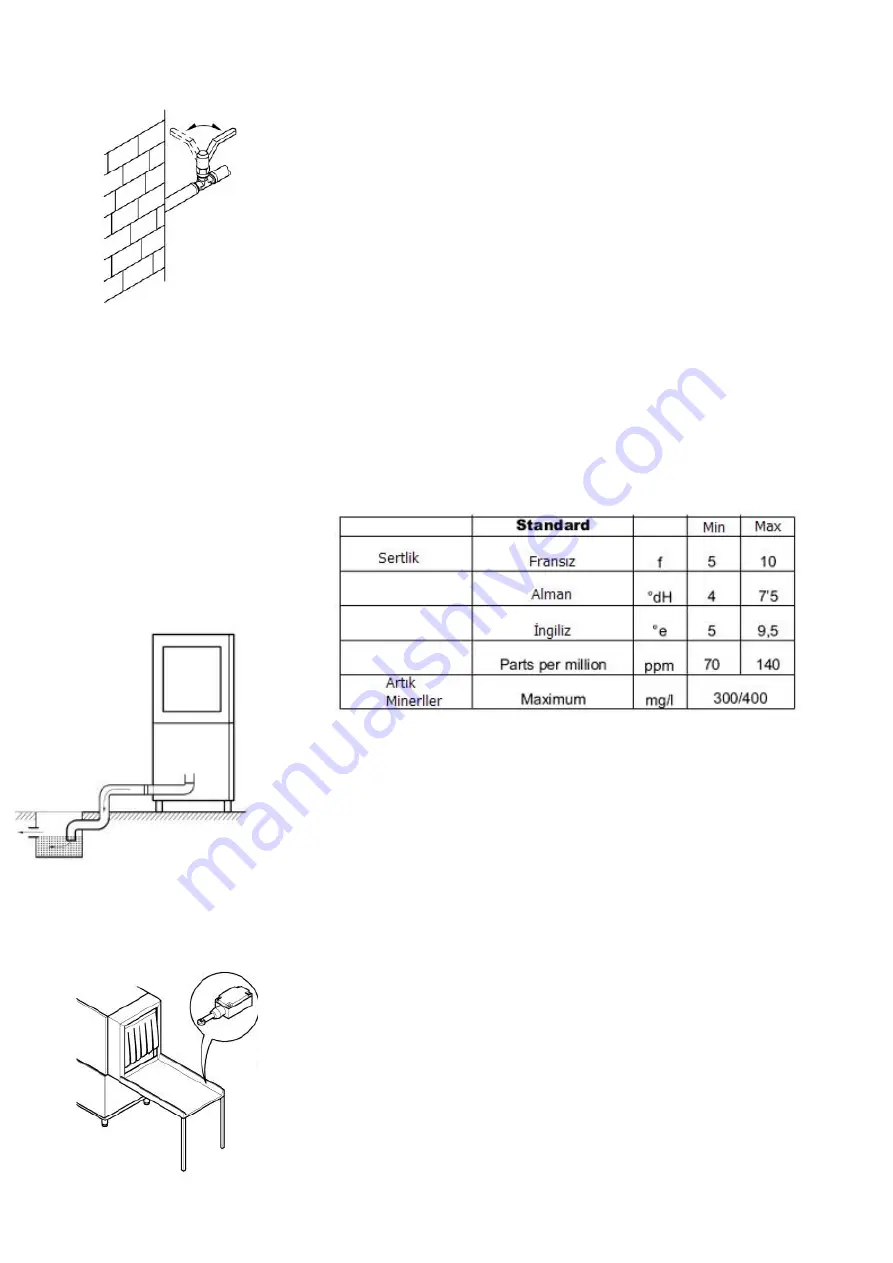

If the water is harder than the values given in the table below, a descaling system should be mounted before the

machine’s water inlet.

If the city water is overloaded with minerals, install an anti-mineral system

before the machine’s water inlet. This way, water hardness will fall down to

the values shown in the table below.

Table 2

Connect the ¾” water inlet pipe located under the machine to a hot water

pipe or a cold-water pipe, if the machine is installed for such a connection.

Battery outlet should be connected to the drainage.

Use a pipe that can endure the working temperature and water

pressure for the machine’s water connection.

10.3 Connection to the drainage

Since the barred machine with conveyor works constantly, drainage should

be effective and located lower than machine outlet.

Consult with the authorized technical service or manufacturing company for

different drainage connections. Use pipes that can endure 70°C temperature

for your machine’s drainage connection. Ground connections should have a

flush drainage pipe to prevent odor.

10.4 Connection to closing switch