TROUBLE SHOOTING

Operating & Maintenance Manual

22478341 (1-15-07) Rev A

49

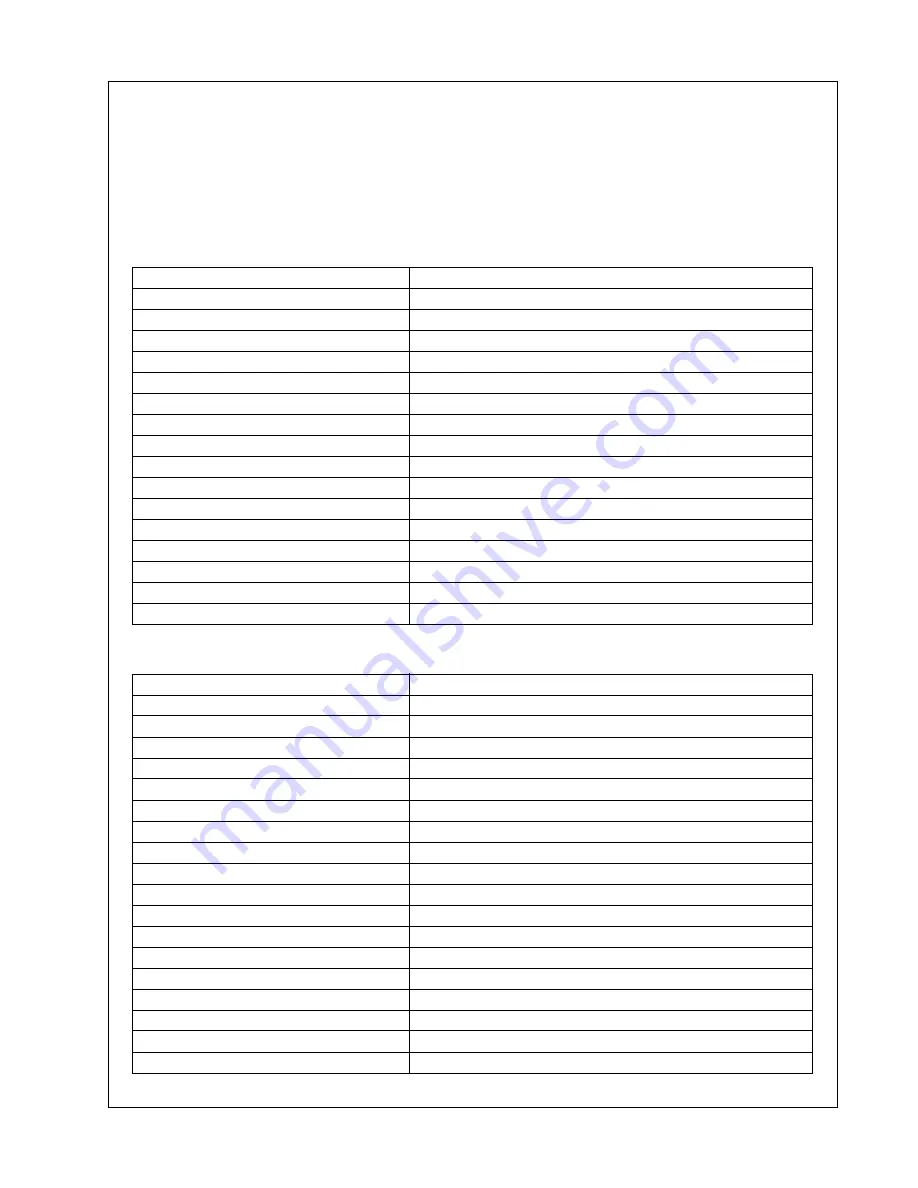

Trouble Shooting Chart

Bold Headings depict the COMPLAINT - Subheadings indicate CAUSES

NOTE: Subheadings suggest sequence to follow troubleshooting.

Table 1: Unit Shutdown

Table 2: Won’t Start/Run:

Cause

Corrective Action

Out of Fuel

Add CLEAN diesel Fuel

Compressor Oil Level Too Low

Add correct oil

Compressor Oil Temp. Too High

See Table 10

Engine Water Temp. Too High

Check coolant level. If necessary, Add.

Loose Wire Connection

Wiggle wires at switches & connector blocks. Make repairs.

Low Fuel Level Shutdown Switch

Replace switch.

Defective Discharge Air Temp. Switch

Replace switch.

Defective Engine Oil Pressure Switch

Replace switch.

Broken Engine Fan Belt

Replace fan belt.

Engine Oil Pressure Too Low

See Table 3 and Table 4.

Defective Shutdown Solenoid

Replace solenoid.

Malfunctioning Relay

Replace relay.

Blown Fuse

Replace fuse/Check for Short.

* < 10 Volts at Shutdown Solenoid

Check battery and alternator. Make repairs.

Engine Malfunctioning

See Trouble Shooting in Engine Section.

Airend Malfunctioning

See Table 10.

Cause

Corrective Action

Out of Fuel

Add CLEAN diesel Fuel

Clogged Fuel Filters

Service filters.

Compressor Oil Level Too Low

Add corrected oil

Loose Wire Connection

Repair or replace connection.

Low Battery Voltage

Check electrolyte level. Check connections.

* <10 Volts at Shutdown Solenoid

Charge battery and alternator. Make repairs.

Defective Alternator

Replace/Repair Alternator

Out of Fuel

Add CLEAN fuel.

Engine Water Temp. Too High

Check fluid level. If necessary, Add.

Malfunctioning Start Switch

Replace switch.

Defective D2 Diode

Replace D2 Diode.

Blown Fuse

Replace fuse/Check for Short.

Engine Oil Pressure Too Low

See Table 3 and Table 4.

Compressor Oil Temp. Too High

See Table 10.

Defective Discharge Air Temp. Switch

Replace switch.

Defective Engine Oil Pressure Switch

Replace switch.

Defective Shutdown Solenoid

Replace solenoid.

Defective Engine Temp. Switch

Replace Switch

Summary of Contents for P250WJD

Page 5: ...22478341 1 15 07 Rev A 3 FOREWORD ...

Page 8: ...6 22478341 1 15 07 Rev A Always use Ingersoll Rand Replacement parts ...

Page 9: ...22478341 1 15 07 Rev A 7 DRAWBAR NOTICE ...

Page 11: ...22478341 1 15 07 Rev A 9 SAFETY ...

Page 15: ...SAFETY Operating Maintenance Manual 22478341 1 15 07 Rev A 13 ...

Page 16: ...Operating Maintenance Manual SAFETY 14 22478341 1 15 07 Rev A ...

Page 18: ...Operating Maintenance Manual SAFETY 16 22478341 1 15 07 Rev A ...

Page 19: ...SAFETY Operating Maintenance Manual 22478341 1 15 07 Rev A 17 ...

Page 21: ...22478341 1 15 07 Rev A 19 NOISE EMISSION ...

Page 27: ...22478341 1 15 07 Rev A 25 GENERAL DATA ...

Page 30: ...28 22478341 1 15 07 Rev A Always use Ingersoll Rand Replacement parts ...

Page 31: ...22478341 1 15 07 Rev A 29 OPERATION ...

Page 38: ...36 22478341 1 15 07 Rev A Always use Ingersoll Rand Replacement parts ...

Page 39: ...22478341 1 15 07 Rev A 37 MAINTENANCE ...

Page 47: ...22478341 1 15 07 Rev A 45 LUBRICATION ...

Page 49: ...22478341 1 15 07 Rev A 47 TROUBLE SHOOTING ...

Page 56: ...54 22478341 1 15 07 Rev A Always use Ingersoll Rand Replacement parts ...