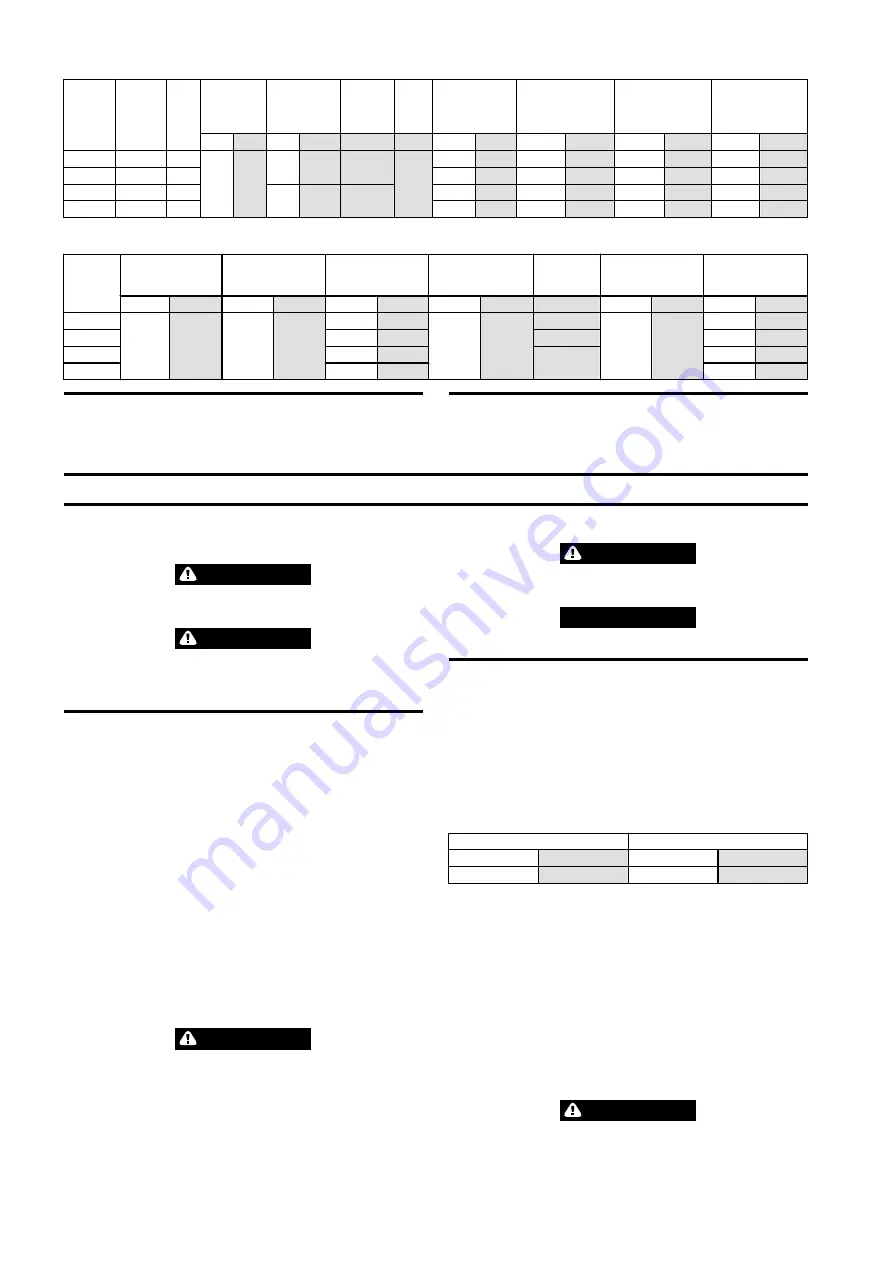

Table 2: Specifications

Hoist

Model

Rated

Capacity

metric

tons

Load

Chain

Falls

Flow

Recommended

Pressure @

Rated Load

Nominal

Hoist

Working

Pressure

Chain

Load

Size

Weight of Chain

per meter of lift

Unit Net Weight with

Standard 10 ft (3 m)

Lift

Minimum

Headroom

Maximum

Lifting

Speed

GPM L/min PSI

bar

bar

mm

lb

kg

lb

kg

in

mm

ft/min

m/min

LC2H060S

6

1

12.7

48

2,466

170

125

16 x 45

12.5

5.7

275

125

28.2

717

18.4

3.7

LC2H120D

12

2

25.1

11.4

375

170

37.2

945

9.2

1.9

LC2H180T

18

3

2,538

175

145

37.6

17.1

610

277

41.9

1,063

6.1

1.25

LC2H250Q

25

4

50.7

23.0

713

325

45.5

1,156

4.6

0.95

Table 3: Trolley Specifications

Hoist

Model

Flow

Travelling

Speed

Minimum

Headroom

Motor Trolley

Hydraulic Pressure

Min/Max

Trolley Flange

Adjustment

Minimum Curve

Radius

Total Weight With

Standard Lift

GPM

L/min

ft/min

m/min

in

mm

PSI

bar

mm

ft

m

lb

kg

LC2H060S

2.6

10

39

12

28.78

731

2,538

175

100–310

10

3

550

250

LC2H120D

39.17

995

130–310

738

335

LC2H180T

47.05

1195

160–310

1437

652

LC2H250Q

48.82

1240

1543

700

n

Capacity Information

LC2H

hoists are designed for lifting with a 5 to 1 minimum safety factor at rated

load.

n

Traceability

Load bearing parts are documented to provide traceability. Documentation includes

chemical and physical properties of raw material, heat treating, and hardening,

tensile and charpy tests as required for the part. Contact factory for documentation.

INSTALLATION

Prior to installing the product, carefully inspect it for possible shipping damage.

Products are supplied fully lubricated from the factory. Check oil levels and adjust as

necessary before operating product. Refer to “LUBRICATION” section on page 7

for recommended oils and lubrication intervals.

WARNING

• Prior to installation refer to Product Safety Information Manual for all

sections of Manual.

CAUTION

• Owners and users are advised to examine specific, local or other regulations,

including American National Standards Institute and/or OSHA Regulations

which may apply to a particular type of use of this product before installing

or putting product to use.

n

Mounting

Make certain your hoist is properly installed. A little extra time and effort in doing

so can contribute a lot toward preventing accidents and helping you get the best

service possible.

Always make certain the supporting member from which hoist is suspended is strong

enough to support weight of hoist, plus weight of maximum rated load, plus a

generous factor of at least 500% of the combined weights.

If hoist is suspended by a top hook, the supporting member should rest completely

within the saddle of the hook and be centered directly above hook shank. Do not use

a supporting member that tilts hoist.

n

Hook Mounted Hoist

Place hook over mounting structure. Make sure hook latch is engaged.

n

Trolley Mounted Hoist

When installing a trolley on a beam, measure beam flange and temporarily install

trolley on the hoist to determine exact distribution and arrangement of spacers.

Adjust spacers in accordance with trolley manufacturer’s literature to provide correct

distance between the wheel flange and beam. The number of spacers between trolley

side plate and mounting lug on the hoist must be the same on both sides in order to

keep hoist centered under I-beam. Remaining spacers must be equally distributed on

the outside of the side plates.

WARNING

• At least one mounting spacer must be used between the head of each trolley

bracket bolt and the trolley bracket and between each trolley bolt nut and

the trolley bracket. Failure to do this could cause hoist to fall when used

improperly.

Ensure trolley hanger capscrews or nuts are torqued in accordance with manufacturer’s

specifications. For installation of hoist and trolley on beam, make certain the side

plates are parallel and vertical.

After installation ensure beam stops are in place, operate trolley over entire length

of beam with a capacity load suspended 4 to 6 inches (10 to 15 cms) off the floor.

CAUTION

• To avoid an unbalanced load which may damage the trolley, the hoist must

be centered under the trolley.

NOTICE

• Trolley wheels ride on the top of the lower flange of the beam.

n

Hydraulic System

Refer to Dwg. MHP3136 on page 9.

n

Hoses

In order to maintain maximum efficiency of product, select size of hydraulic lines

according to maximum volume of oil to be used. If hydraulic lines used are too small,

they may cause excessive back pressure, generating heat and causing inefficiency

within the hydraulic system. Sizes in Table 4 ‘Hose Recommendations’ on page 4,

are to be used as a guide only. If trouble is experienced due to the use of long hoses,

it may be necessary to use hoses which are one size larger.

Table 4: Hose Recommendations

Oil Flow @ 3000 PSI max.

Pressure Hoses (inside diameter)

GPM

L/min

inch

mm

12.7

48

n

Fluid

The most frequent cause of malfunction or failure of hydraulic equipment is presence

of contaminants in hydraulic fluid. Reduce contaminants by using clean hydraulic

fluid, and changing the fluid before it deteriorates. When hydraulic fluid is changed,

also clean out the hydraulic reservoir. At a minimum, the required oil cleanliness level

is ISO 18/13 or better. Periodic checks which may be performed by the operator to

test hydraulic fluid cleanliness include:

1. Check for a major change in color or noticeable thickening, which are signs of

severe deterioration and indicate the need to change the fluid.

2. Check oil for foaming and aeration which may indicate low oil level in hydraulic

tank, leaks, faulty hydraulic line connections or moisture build-up in oil.

ISO VG 30, 46 and 68 oils will give good results under normal temperature conditions.

The use of an oil having a high viscosity index will minimize cold-start trouble and

reduce the length of warm-up periods. A high viscosity index will minimize changes

in viscosity with corresponding changes in temperature.

CAUTION

• Do not substitute synthetic fluids unless it has been determined that hoist,

motor and hydraulic system seals are compatible.

4

Form MHD56465 Edition 3