16575003_ed1

EN-4

EN

counterclockwise

to tighten them. Tighten the joint

between 20 and 25 ft.-lb. (27.1 and 33.9 Nm) torque.

15. Using finger pressure, press the Seal Cup Assembly (55),

felt end trailing, onto the rotor end of the Collet Body (58).

Press the Cup Assembly to the shoulder of the Collet

Body. Saturate the felt with

Ingersoll Rand

No. 50 Oil.

16. Insert a 5/32" pin through the opening in the Extension

Housing and the cross hole in the Spindle to keep the

Spindle from rotating. Thread the Collet Body and Seal

Cup Assembly onto the Spindle and tighten it between 14

and 19 ft.-lb. (19 and 26 Nm) torque. Install the Extension

Housing Plug (52).

17. Slide the Spindle Bearing Shield (56), large opening first,

over the Collet Body and into the Extension Housing.

Using snap ring pliers, install the Shield Retainer (57) in

the internal groove in the Extension Housing.

18. Slide the Handle Clamp (61) with the assembled handle

onto the Extension Housing and position the handle in

the most comfortable position. Tighten the Mounting

Screw Nut (64) between 10 and 12 ft.-lb. (13.5 and 16.3

Nm) torque.

19. Insert the Collet (59) into the Collet Body and thread the

Collet Nut (60) onto the Collet Body.

20. Use the Collet Body Wrench (82) on the flats of the Collet

Body and the Collet Nut Wrench (81) on the Collet Nut to

tighten the Collet Nut.

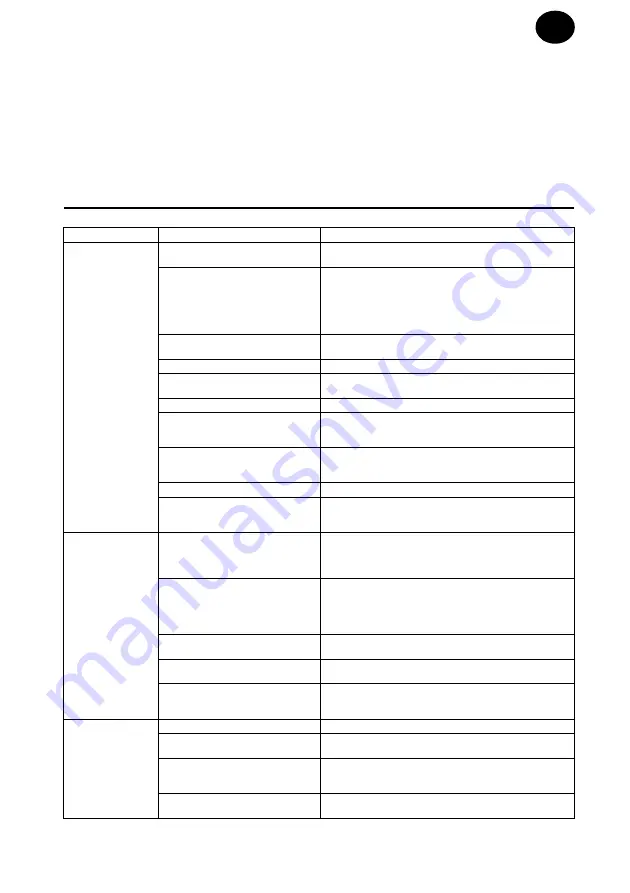

Troubleshooting Guide

Trouble

Probable Cause

Solution

Low power or low free

speed

Insufficient air pressure

Check air line pressure at the Inlet of the Tool. It must be 90

psig (6.2 bar/620 kPa).

Clogged muffler elements

Disassemble the Tool and agitate bare Motor Housing and

Flange in clean kerosene. Back flush muffler elements by

blowing into the exhaust ports with an air gun until all

contaminants and obstructions are removed. If elements

cannot be cleaned, replace the Motor Housing and/or the

Flange.

Plugged Inlet Screen (2)

Clean the Inlet Screen with a stream of air or replace the

Screen.

Worn or broken Vanes (17)

Install a

complete

set of new Vanes.

Loose Extension Housing (51) or Gear

Case Adapter (32)

Tighten the Housing or Adapter to 20 to 25 ft.-lb. (27 to 34 Nm)

torque.

Worn or broken Motor Housing (9)

Replace the Motor Housing.

Internal air leakage in the Motor

Housing indicated by high air

consumption/low speed.

Replace the Motor Housing.

Grit buildup under the Throttle Lever

(10) restricting full Throttle Valve

Plunger (12) movement.

Remove the Throttle Lever and clean the groove in the Motor

Housing.

Bent stem on Throttle Valve (6)

Replace the Throttle Valve.

Front Seal Cup Assembly (20) dragging

against the shield of the Front Rotor

Bearing (21)

Reposition the Front Seal Cup Assembly.

Rough operation /

vibration

Improper lubrication or dirt buildup

Inject 3 cc of clean kerosene into the Inlet, operate the Tool for

30 seconds and

immediately

inject 3 cc of the recommended

oil into the Inlet and run the Sander long enough to coat the

internal parts with the oil.

Worn or broken Rear Rotor Bearing

(13) or Front Rotor Bearing

Replace the worn or broken Bearings. Examine the Front End

Plate (18), Front End Plate Spacer (19), Front Seal Cup

Assembly (20) and Rear Rotor Bearing Spacers (14) and

replace any damaged parts. If the attached rotor plate is

damaged, replace the Rotor (16).

Worn or broken Rear Spindle Bearing

(49) or Front Spindle Bearing (53)

Replace the Bearings.

Dirt contaminated Front Spindle

Bearing

Replace the Bearing.

Worn, bent or broken Spindle (44)

Replace the Spindle if, when mounted between centers, the

runout on the spindle body exceeds 0.002" T.I.R. or 0.0005"

T.I.R. on the bearing mounting diameters.

Excessive runout

Loose Collet Nut (60)

Tighten the Collet Nut until snug.

Worn or damaged Collet (59), Collet

Nut or Collet Body (58)

Replace the damaged component and retest.

Bent, worn or broken Spindle

Replace the Spindle if, when mounted between centers, the

runout on the spindle body exceeds 0.002" T.I.R. or 0.0005"

T.I.R. on the bearing mounting diameters.

Worn or damaged Front Spindle

Bearing

Replace the Front Spindle Bearing.