25

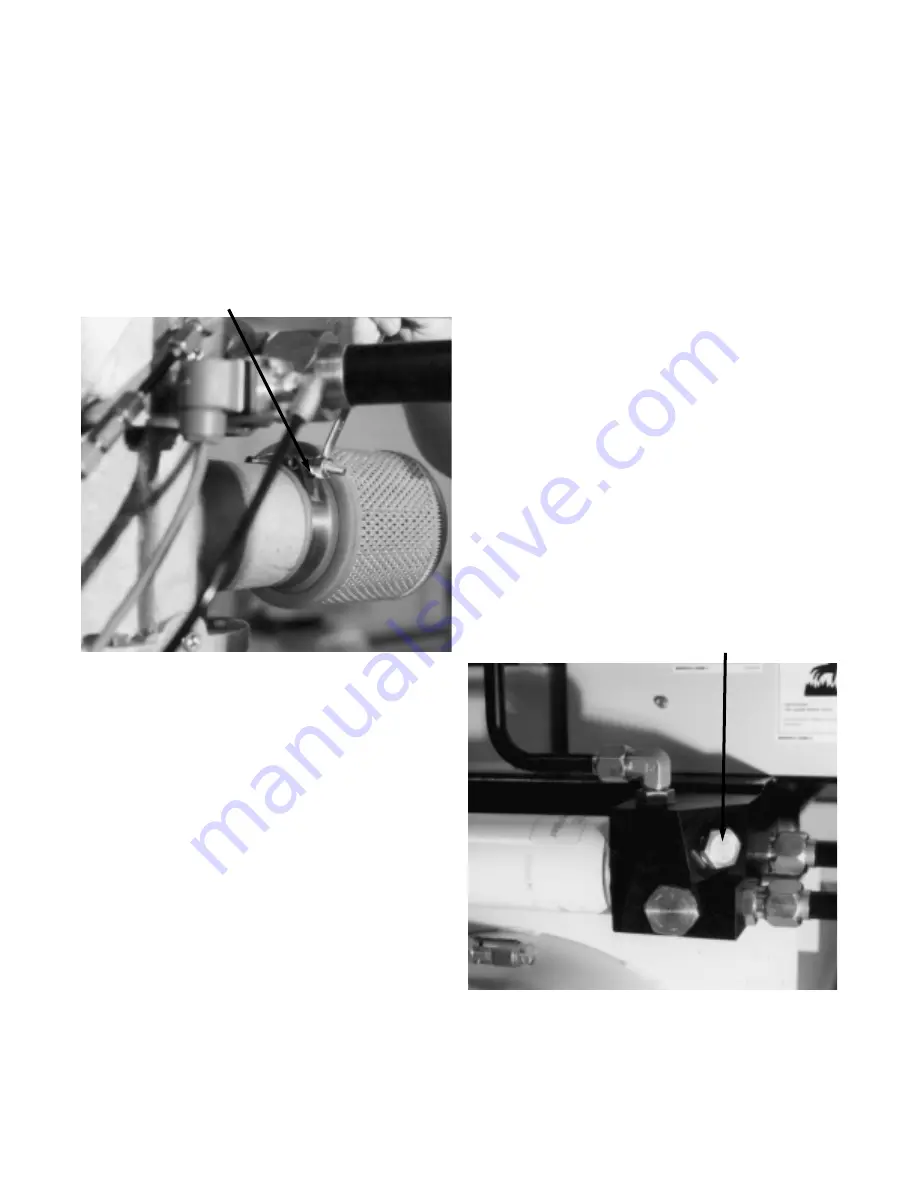

4.9 INLET AIR FILTER ELEMENT

The inlet air filter should be changed at the interval

shown in the maintenance chart or any time the filter

becomes dirty.

The filter element is not washable and must be

replaced. Remove the filter by loosening the clamp on

the filter assembly located on the Inlet Control Valve.

Remove and discard the old filter element. Install a

new filter element. Tighten clamp (See Figure 4.9-1).

FIGURE 4.9-1 INLET AIR FILTER

4.10 COOLANT FILTER

Time of change - after the first 150 hours and every

1000 hours thereafter, or when the coolant is being

changed. In dirty operating environments, the filter

should be changed more frequently.

Before beginning any work on the compressor, open,

lock and tag the main electrical disconnect and close

the isolation valve on the compressor discharge. Wait

2 minutes after stopping to allow internal pressure to

dissipate. Vent residual pressure from the unit by slow-

ly unscrewing the coolant fill plug one turn.

Unscrewing the fill plug opens a vent hole, drilled in

the plug, allowing the pressure to release to atmos-

phere (See Figure 4.3-1). A slight mist or oil droplets

may be visible during venting. Do not remove fill plug

until all pressure has vented from the unit. Also vent

piping by slightly opening the drip leg valve . When

opening the drain valve or removing the coolant fill

plug, stand clear of the valve discharge, wear work

gloves and appropriate eye protection.

SPECIAL TOOLS

Suitable clean drain pan or container to hold coolant

drained from unit.

A quantity of proper coolant sufficient to top off the

coolant level in the compressor.

One genuine IR replacement coolant filter of the prop-

er type for the unit.

1. Place a clean pan under the coolant filter.

2. Using a filter wrench, remove the coolant filter.

Remember that the filter and coolant may be hot!

3. Discard the old filter.

4. Wipe the sealing surface of the filter head with a

clean lint-free rag to prevent entry of dirt into the sys-

tem.

5. Remove the replacement filter from its protective

package.

6. Apply a small amount of clean coolant on the rubber

seal of the filter.

7. Screw filter on until the seal makes contact with the

seat on the filter header. Tighten approximately one

half to three quarters turn additional.

8. Remove coolant fill plug (See Figure 4.10-1).

FIGURE 4.10-1 FILL PLUG

CLAMP

FILL PLUG

Summary of Contents for EP 20-ESP

Page 35: ...33 6 0 REFERENCE DRAWINGS 6 1 ELECTRICAL SCHEMATIC FULL VOLTAGE 39884143 REV 01...

Page 36: ...34 6 2 ELECTRICAL SCHEMATIC STAR DELTA 39884150 REV 01...

Page 38: ...36 6 4 FOUNDATION PLAN TANK MOUNTED CONTINUED 39871975 REV 03...

Page 39: ...37 6 4 FOUNDATION PLAN TANK MOUNTED 39871975 REV 03...

Page 40: ...38 6 5 FOUNDATION PLAN BASE MOUNTED CONTINUED 39872835 REV 03...

Page 41: ...39 6 5 FOUNDATION PLAN BASE MOUNTED 39872835 REV 03...

Page 44: ...42 39876461 REV 02...

Page 46: ...44 39880844 REV 01...

Page 48: ...46 39872031 REV 01 SEE PIPING ASSEMBLY OPTIONS...

Page 52: ...50 39872023 REV 02 TO AFTERCOOLER TO AFTERCOOLER...

Page 57: ...55 DATE RUN TIME WORK DONE QTY UNIT WORK HOURS MEASURE BY 8 0 MAINTENANCE RECORD...

Page 58: ...56 DATE RUN TIME WORK DONE QTY UNIT WORK HOURS MEASURE BY MAINTENANCE RECORD...