21

Using the Wireless Remote Control

To change system configurations using the Wireless Remote Control, follow this procedure:

1.

Remove the batteries from the remote control, and re-insert them while pressing the Temp+ and

Temp- buttons simultaneously (refer to

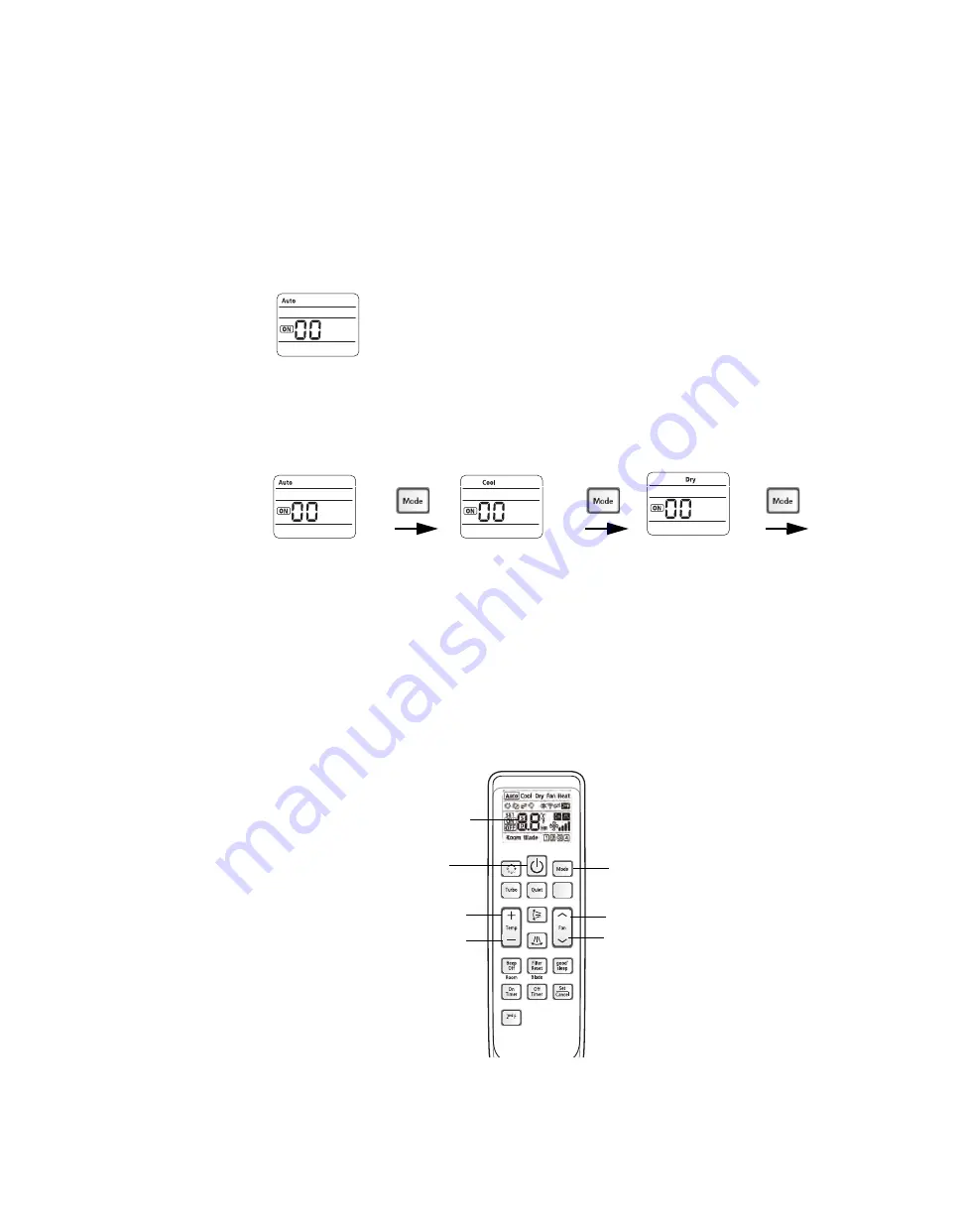

The first 2-digit segment of a 24-digit sequence will appear on the wireless remote control

display, as shown:

2. To advance to the next 2-digit segment, press the Mode button (

). Continue

pressing the Mode button until the two-digit segment appears that corresponds to the option

setting or address setting you want to view or change.

Each 2-digit segment is differentiated from the others by a combination of operation mode

(Auto/Cool/Dry...) and ON/OFF icons, as shown below. (See “The 2-Digit Segments,” for more

detailed information.)

Digits 2 and 3

Digits 4 and 5

Digits 6 and 8

...and so on, through

digits 23 and 24.

Note:

Digits 1, 7, 13, and 19 do not appear and are not used for configuration.

3. To change the value of the left digit on the display, press the Fan down button.

To change the value of the right digit on the display, press the Fan up button.

Note:

Values and their corresponding settings are listed in the following pages of this section

of the manual.

4. To save the setting, press the Power button twice.

5. To restore the wireless remote control to normal operating mode, remove the batteries from

the remote control. Then re-insert them.

Figure 3.

Mode button

Fan up

Fan down

Power button

2-digit segment

Note:

The wireless remote control may

look different from the illustration,

depending on the model.

Temp up

Temp down

Wireless Remote Control