Delta Treatment Systems • 9125 Comar Drive, Walker, LA 70785 • 1-800-219-9183 • www.deltatreatment.com

9

INSTALLATION INSTRUCTIONS

B. If using the linear blower (Thomas model LW250) attach

the 1-inch galvanized male adapter to the blower using

the supplied hose and clamps. Next attach the 2-inch

Schedule 40 PVC reducer to the male adapter, then

connect the PVC line to the reducer using PVC solvent.

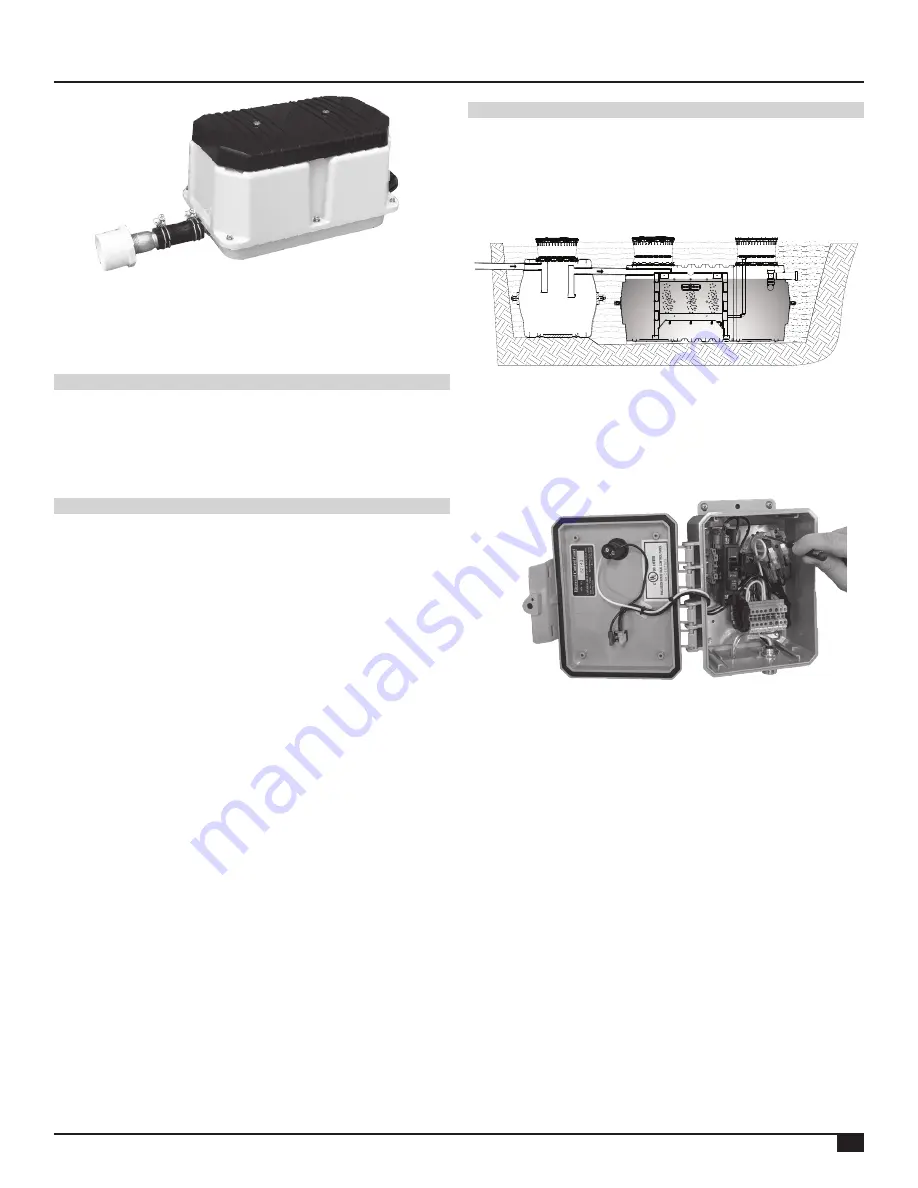

7. Air Compressor Placement

Do not install the air pump(s) in a low-lying area where water

may accumulate. The air pump should be installed near the

control panel and within 100 ft. of the reactor tank. The air pump

can be installed outdoors or in a clean, well ventilated area, such

as a tool room, garage, etc.

8. Mounting Control Panel

Mount the control panel in a location such that the alarm can

be heard and be readily observed. The control panel must be

connected to a 20-amp maximum electrical source equipped

with a ground fault interrupter (GFI) circuit breaker. Install a

power disconnect switch to the panel that is operable and

available to a maintenance provider. The control panel must

be grounded. Connect the source ground wire to the ground

location in the panel. All electrical work shall be done according

to NEC and local code requirements.

A. Attach control panel to a suitable mounting surface. Use

appropriate screws for all four mounting holes on the

back of the enclosure.

B. The control panel contains a fuse or circuit breaker for

the air pump. An electrical malfunction in the air pump,

or wiring to the air pump, will cause the fuse or circuit

breaker to blow. The control panel also contains a

pressure switch and visual and audible alarms. Loss of

air pressure caused by air pump system malfunction, or

a high-water level in the treatment tank, will cause the

alarm to sound and light to illuminate.

C. Control panel is rated for outdoor service. However, do

not place it where it can be immersed in rising water or

where runoff water such as from a roof will pour onto

it. Do not mount it where it is subject to wetting from

sprinklers, hoses, etc.

D. Connect conduit. After the control panel is properly

mounted, connect conduit and install wiring as shown

on drawings bound herein (Schematics).

E. Connect the pressure air tubing to the 1/8” barb-fitting

in the air piping system. The air tubing should be

protected by conduit as shown on the drawing.

9. System Startup

Turn power on. Once the tank water level reaches the outlet tee,

turn power on to control panel. Air pump should start.

A. Set the high-level pressure switch.To set the high-level

pressure switch that detects high water level in the unit

bring the tank to operating water level with compressor

turned on. Using properly sized screwdriver turn high

level alarm adjustment screw clockwise until alarm

occurs. Then turn the screw counterclockwise until

alarm stops.

B. Check air piping joints for leakage using a soapy water

solution. Repair if necessary and then carefully backfill

air distribution piping and tanks.

C. Finish grade the site. Divert surface water away from

the system and install or plant ground cover to prevent

erosion.

D. Tank is ready to receive incoming sewage. No special

start-up procedures are required. The process is

naturally occurring and does not require any special

additives.

E. Replace and secure all tank access lids. Close up the

enclosure door on control panel and lock if necessary.

F. Spend time with your customer whenever possible.

Review operation instructions. Be sure that the

customer has a manual to keep. This saves valuable

time avoiding return visits.

G. Retain these instructions for future reference.

WARNING: CONTROL PANEL CONTAINS HIGH VOLTAGE

AND MUST BE INSTALLED AND SERVICED ONLY BY

QUALIFIED PERSONNEL

Figure 5