15

OPERATION

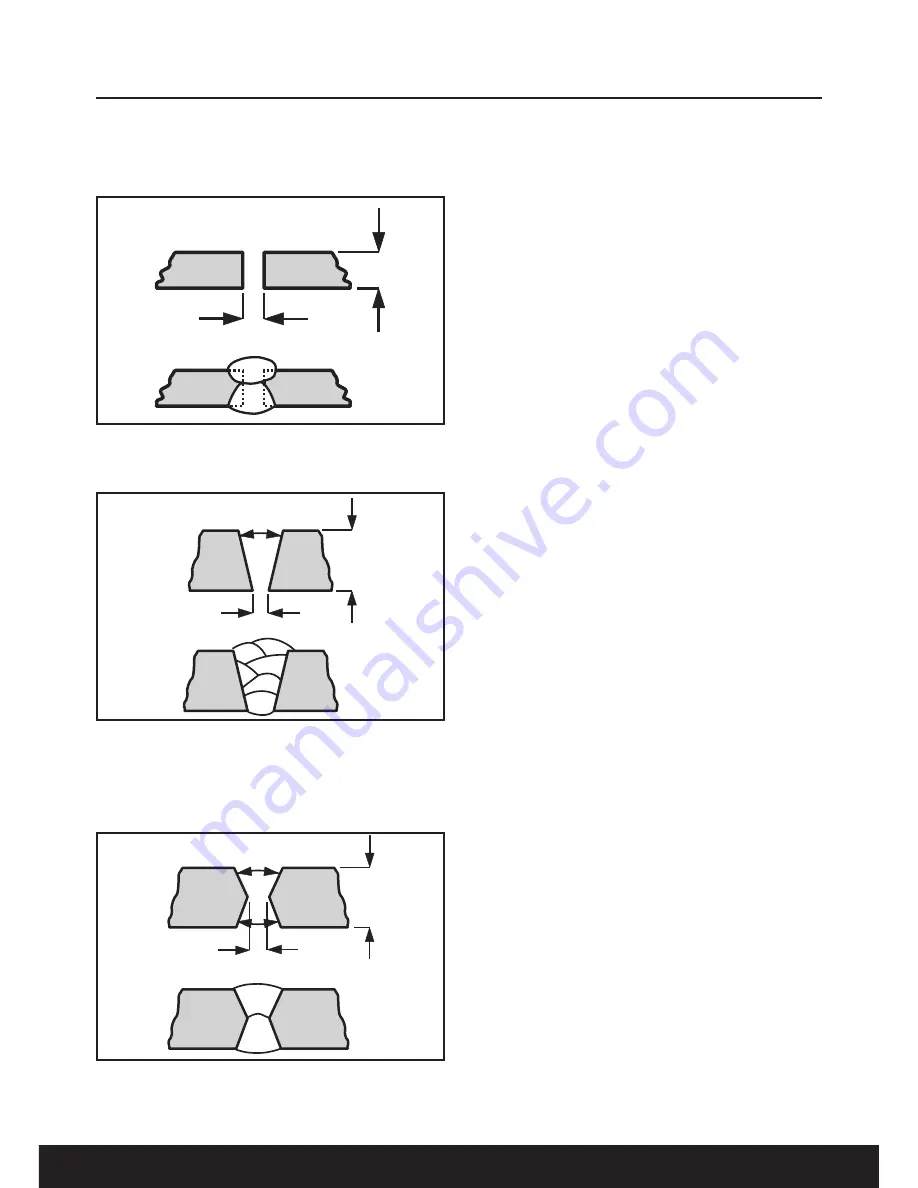

When welding material up to 7mm in thickness

place the pieces 2-3mm apart, run the welding

bead along the join. A second bead can go

along the underside for extra strength (Fig.10).

When welding material from 7mm to 30mm thick

prepare the material as shown in Fig.11 filling up

the space with several layers of weld.

When welding together material over 30mm in

thickness prepare the material as shown in

Fig.12 filling up the space with several layers of

weld, welding each side in turn with each

welding pass.

Disconnect the Welding Power Supply from the

mains supply before changing or removing

electrodes. Use pliers to remove used

electrodes from the electrode holder or to move

the welded pieces.

The Manual Metal Arc Process

When an arc is struck between the metal rod

(electrode) and the workpiece, both the rod and

workpiece surface melt to form a weld pool.

Simultaneous melting of the flux coating on the

rod will form gas and slag which protects the

weld pool from the surrounding atmosphere. The

slag will solidify and cool and must be chipped

off the weld bead once the weld run is complete

(or before the next weld pass is deposited).

The process allows only short lengths of weld to

be produced before a new electrode needs to

be inserted in the holder. Weld penetration is low

and the quality of the weld deposit is highly

dependent on the skill of the welder.

Types of Flux/Electrodes

Arc stability, depth of penetration, metal

deposition rate and positional capability are

greatly influenced by the chemical composition

of the flux coating on the electrode. Electrodes

can be divided into three main groups:

• Cellulosic

• Rutile

• Basic

Cellulosic electrodes

contain a high proportion

of cellulose in the coating and are characterised

by a deeply penetrating arc and a rapid burn-off

rate giving high welding speeds. Weld deposit

can be coarse and with fluid slag, deslagging

can be difficult. These electrodes are easy to

use in any position and are noted for their use in

the stovepipe (vertical down position) welding

technique.

Features:

•

• Deep penetration in all positions

• Suitability for vertical down welding

• Reasonably good mechanical properties

• High level of hydrogen generated - risk of

cracking in the heat affected zone

Fig 10

7mm

2-3mm

Fig 11

>30mm

60º

2-3mm

1

2

4

3

5

6

Fig 12

>30mm

60º

2-3mm

Summary of Contents for IM-MMA140

Page 2: ...Always Read Instruction Manual Retain for Future Reference IM MMA140 140A MMA WELDER...

Page 22: ...21 NOTES...

Page 23: ...22 NOTES...

Page 24: ...23 NOTES...