16

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

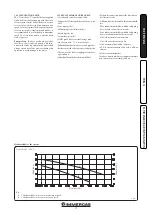

1.22 GAS SYSTEM START-UP.

To start up the system, refer to the technical

standard in force: This divides the systems and

therefore the start-up operations into three

categories: new systems, modified systems,

re-activated systems.

In particular, for new gas systems:

-

open windows and doors;

- avoid presence of sparks or open flames;

- bleed all air from the pipelines;

- check the seal of the internal system by follow-

ing the instructions provided by the technical

regulations in force (refer to the pertaining lo-

cal regulations for the "sealing test" on systems

served by single or cascade generators with a

nominal thermal capacity greater than 35 kW.

1.23 BOILER START UP (IGNITION).

In order to issue the Declaration of Conformity

required by the regulations in force, one must

fulfil the following requirements to commission

the boiler (the operations listed below must only

be performed by qualified personnel and in the

presence of staff only):

- check that the internal system is properly sealed

according to the specifications set forth by

regulations in force; Up to operating pressures

of 40 mbar it is also possible to use the testing

method adopted by the technical regulations

in force for systems served by single appliances

(or in cascade set-up), with nominal thermal

capacities greater than 35 kW. For greater pres-

sure levels you will need to refer to legislation

in force and/or other effectively tried and tested

methods;

- make sure that the type of gas used corresponds

to boiler settings;

- check that there are external factors that may

cause the formation of fuel pockets;

- switch the boiler on and check correct ignition;

- make sure the fan rpm matches the value pro-

vided in the book (Par. 3.17);

- ensure that the safety device intervenes in the

event of gas supply failure and check the relative

intervention time;

- check activation of the main switch located

upstream from the boiler and in the boiler;

- check that the intake/exhaust concentric ter-

minal (if fitted) is not blocked.

The boiler must not be started up even if only

one of the checks should be negative.

N.B.:

The Immergas Authorised After-sales Centre

can carry out the initial boiler check (point 2.1)

required to activate the warranty of Immergas

solely upon completion of commissioning by an

installer. The test certificate and warranty is issued

to the user.

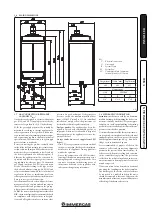

1.18 FLUE DUCT SYSTEMS FOR VOIDS

AND CHIMNEYS.

Flue ducts may be installed in suitable voids or

chimneys provided that the relevant building

regulations permit this. Flue ducting systems

must be installed in strict accordance with the

manufacturers instructions.

Immergas ducting system Ø 80 .

The "Green

Series" 80 Ø flexible ducting system must only be

used with Immergas condensing boilers.

In any case, ducting operations must respect

the provisions contained in the standard and in

current technical regulations; in particular, the

declaration of conformity must be compiled at

the end of work and on commissioning of the

ducted system. The instructions in the project

or technical report must likewise be followed, in

cases provided for by the standard and current

technical regulations. The system or components

of the system have a technical life complying with

current standards, provided that:

- it is used in average atmospheric and envi-

ronmental conditions, according to current

regulations (in particular, by the standards

regarding: absence of combustion products,

dusts or gases that can alter the normal ther-

mophysical or chemical conditions; existence

of temperatures coming within the standard

range of daily variation, etc.).

- Installation and maintenance must be per-

formed according to the indications supplied

by the manufacturer and in compliance with

the provisions in force.

- The max. possible length of the 80 Ø flexible

ducting vertical section

is equal to 24.0 m for

Victrix Pro 35 1 I and 30.0 m for Victrix Pro

55 1 I

. This length is obtained considering the

complete exhaust terminal, 1m of 80 Ø pipe

in exhaust, two 90° 80 Ø bends at the boiler

outlet to connect to the ducting system and two

direction changes of the flexible tube inside the

flue/technical slot.

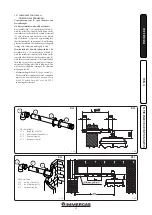

1.19

FLUE EXHAUST WITH BOILERS IN

CASCADE.

The boilers installed in cascade composed of

any number between 2 and 5 boilers, can be

manifolded to a unique flue exhaust pipe, which

flows into a flue.

Immergas supplied an appropriate and original

flue exhaust system separately to the boilers.

1.20 SYSTEM FILLING.

When the boiler has been connected, fill the sys-

tem. Filling is performed at low speed to ensure

release of air bubbles in the water via the boiler

and heating system vents.

The boiler incorporates two automatic vent

valves fitted on the circulator pump and on the

condensing module. Check if the cap is loose.

Open the radiator vent valves. Close radiator

vent valves when only water escapes from them.

N.B.:

during these operations start up the cir-

culation pump at intervals, acting on the main

switch positioned on the control panel.

Vent the

circulation pump by loosening the front cap and

keeping the motor running

. Tighten the cap after

the operation.

Attention:

this boiler is

not

equipped with an

expansion vessel on the system. It is mandatory

to install a closed expansion vessel to guarantee

correct boiler operation. The expansion vessel

must comply with the European Standards in

force. The dimensions of the expansion vessel

depend on the data relative to the central heating

system. Install a vessel whose capacity responds

to the requisites of the Standards in force (''R''

collection).

1.21 CONDENSATE TRAP FILLING.

On first lighting of the boiler combustion prod-

ucts may come out the condensate drain; after a

few minutes’ operation check that this no longer

occurs. This means that the trap is filled with

condensate to the correct level preventing the

passage of combustion products.

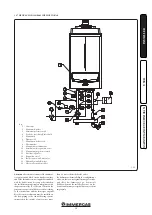

B23

1-23

Exhaust

Exhaust

Summary of Contents for VICTRIX PRO 35 1 I

Page 1: ...VICTRIX PRO 35 55 1 I IE Instruction and warning book 1 038715ENG...

Page 2: ......

Page 42: ......

Page 43: ......