3-4

3-5

+

+

3

12

2

1

P1

P3

+

+

3

12

1

P1

2

P3

32 - IE

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

3.5 CONVERTING THE BOILER TO

OTHER TYPES OF GAS.

If the boiler has to be converted to a different gas

type to that specified on the data plate, request

the relative conversion kit for quick and easy

conversion.

The gas conversion operation must be carried

out by an authorised company (e.g. Immergas

After-Sales Technical Assistance Service).

To convert to another type of gas the following

operations are required:

- disconnect the appliance;

- replace the nozzle located between the gas pipe

and gas/air mixing sleeve (Part. 7 Fig. 1-28),

taking care to disconnect the appliance during

this operation;

- re-power the appliance;

- calibrate the number of fan revolutions (parag.

3.6);

- adjust the correct air/gas ratio (parag. 3.7);

- seal the gas flow rate regulation devices (if

settings are modified);

- after completing the conversion, apply the

sticker, contained in the conversion kit, near

the data-plate. Using an indelible marker pen,

cancel the data relative to the old type of gas.

These adjustments must be made with reference

to the type of gas used, following that given in

the table (Par. 3.20).

3.6 CALIBRATION OF NUMBER OF FAN

REVS.

Attention:

verification and calibration is

necessary, in the case of transformation to other

types of gas, in the extraordinary maintenance

phase with replacement of the circuit board,

air/gas circuit components or in the case of

installations with fume extraction systems, with

horizontal concentric pipe measuring more

than 1 metre.

The boiler heat output is correlated to the

length of the air intake and flue exhaust pipes.

This decreases with the increase of pipe length.

The boiler leaves the factory adjusted for

minimum pipe length (1m). It is therefore

necessary, especially in the case of maximum pipe

extension, to check the ∆p gas values after at least

5 minutes of the burner operating at nominal

heat output, when the temperatures of the intake

air and exhaust flue gases have stabilised. Adjust

the nominal and minimum heat output in the

domestic hot water and central heating modes

according to the values in the table (Par. 3.19)

using the differential manometers connected to

the ∆p gas pressure points (15 and 16 Fig. 1-28).

Access menu “M5” (Parag. 3.9) and adjust

the ignition power “P50”, while within item

“SERVICE” adjust the following parameters:

- boiler maximum heat output “P62”;

- boiler minimum heat output “P63”;

- maximum central heating output “P64”;

- minimum central heating output “P65”.

Listed below are the default settings featured

on the boiler:

Magis Victrix

P50

36 %

40%

P62

G20:

5500 (rpm)

LPG:

5000 (rpm)

P63

G20:

1000 (rpm)

LPG:

1000 (rpm)

P64

G20:

5000 (rpm)

LPG:

4500 (rpm)

P65

G20:

1000 (rpm)

LPG:

1000 (rpm)

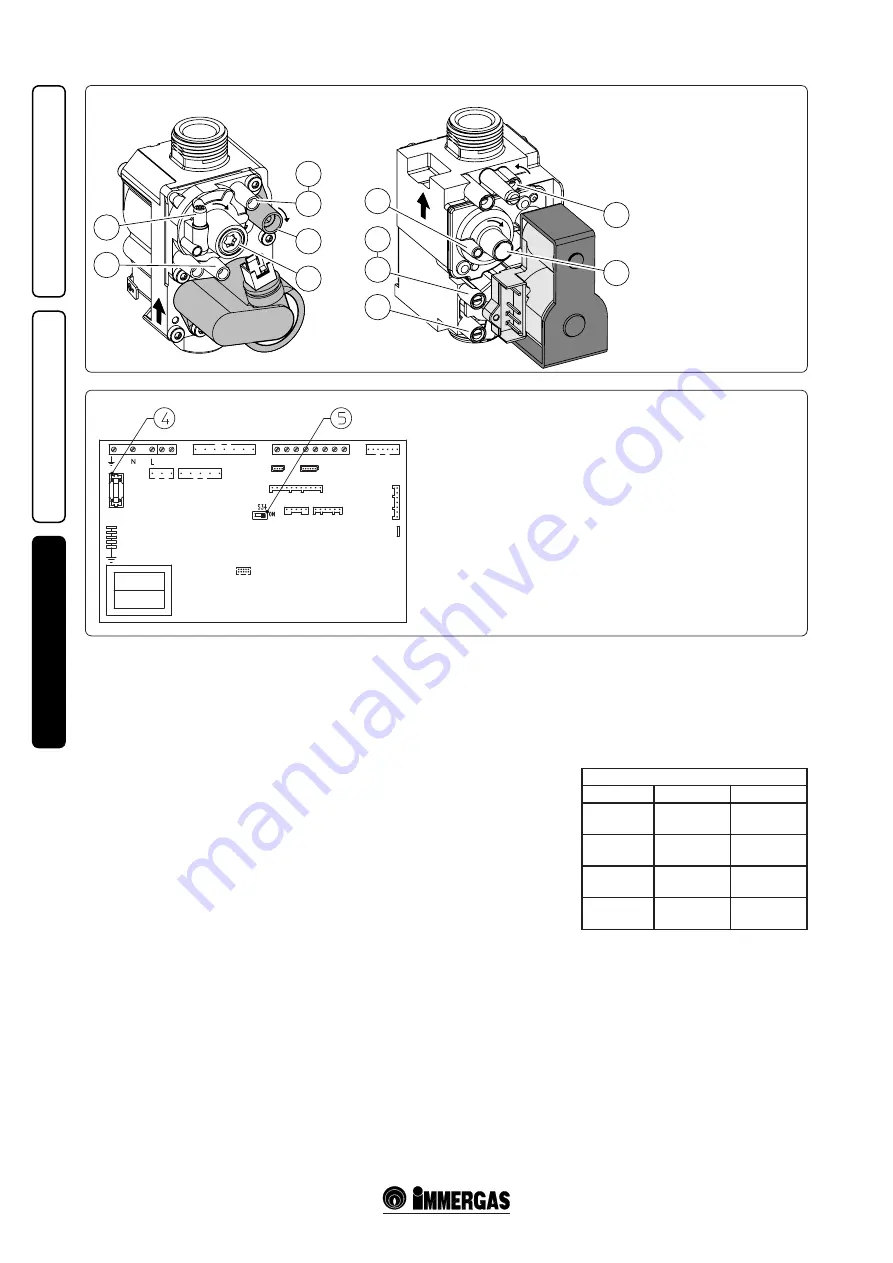

P.C.B.

Key:

1 - Gas valve inlet pressure

point

2 - Gas valve outlet pressure

point

3 - Off/Set adjustment screw

12 - Outlet gas flow rate

regulator

Gas Valve 8205

Gas Valve 848

Key:

4 - Fuse 3.15 AF

5 - Selector S34: must be set on On

Summary of Contents for MAGIS Victrix

Page 1: ...MAGIS Victrix IE Instruction and warning book 1 035518ENG ...

Page 2: ......

Page 42: ......

Page 43: ......