8

1-5

1-4

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

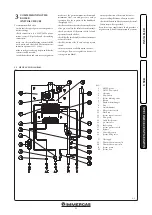

1.9 FLUE SYSTEMS.

The manufacturer suggests the use of your own

flue installation by supplying various solutions

separately from the boilers regarding the instal-

lation of air intake terminals and flue exhaust,

which are fundamental for boiler operation.

Attention: the boiler must only be installed

together with an original Immergas air intake

and flue gas exhaust system, except for the C6

configuration, in compliance with the stan-

dards in force. This system can be identified by

an identification mark and special distinctive

marking bearing the note " not for condensing

boilers".

The flue exhaust pipes must not be in contact with

or be near to flammable materials. Moreover,

they must not pass through buildings or walls

made of flammable material.

• Resistance factors and equivalent lengths. Each

flue component has a

Resistance Factor

based

on experimental tests and specified in the table

below. The Resistance Factor for individual

components is independent from the type of

boiler on which it is installed and has a dimen-

sionless size. It is however, conditioned by the

temperature of the fluids that pass through the

pipe and therefore, varies according to applica-

tions for air intake or flue exhaust. Each single

component has a resistance corresponding to

a certain length in metres of pipe of the same

diameter; the so-called

equivalent length

,

can be obtained from the ratio between the

relative Resistance Factors.

All boilers have an

experimentally obtainable maximum Resistance

Factor equal to 100.

The maximum Resistance

Factor allowed corresponds to the resistance

encountered with the maximum allowed pipe

length for each type of Terminal Kit. This

information allows calculations to be made to

verify the possibility of setting up various flue

configurations.

N.B.:

to dimension the flue ducting using commer-

cial components, refer to the table of combustion

parameters (Paragr. 3.16).

1-5

1-4

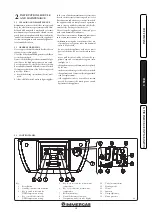

1.8 REMOTE CONTROLS AND

ROOM CHRONO-THERMOSTATS

(OPTIONAL).

The boiler is prepared for the application of room

chrono-thermostats or remote controls, which

are available as optional kits (Fig. 1-4; 1-5).

All devices are connected with 2 wires only. Ca-

refully read the user and assembly instructions

contained in the accessory kit.

• On/Off digital chrono-thermostat. The chrono-

thermostat allows:

- set two room temperature value: one for day

(comfort temperature) and one for night

(reduced temperature);

- set a weekly programme with four daily

switch on and switch off times;

- selecting the required function mode from

the various possible alternatives:

• manual mode (with adjustable temperature).

• automatic mode (with set programme).

• forced automatic mode (momentarily changing

the temperature of the automatic programme).

The chrono-thermostat is powered by two 1.5V

LR 6 type alkaline batteries.

• Digital Remote Mini-Control Device with cli-

mate chrono-thermostat and CAR

V2

function.

In addition to the functions described in the

previous point, the Mini-DRC and CAR

V2

panels enable the user to control all the im-

portant information regarding operation of the

appliance and the central heating system with

the opportunity of easily intervening on the

previously set parameters without having to go

to the place where the appliance is installed. The

Mini CRD and CAR

V2

panels are equipped with

self-diagnosis to display any boiler functioning

anomalies. The climate regulator incorporated

into the remote panels enables the system flow

temperature to be adjusted to the actual needs

of the room being heated, in order to obtain

the desired room temperature with extreme

precision and therefore with evident saving

in running costs. The Mini CRD and CAR

V2

are fed directly by the boiler by means of the

same 2 wires used for the transmission of data

between the boiler and devices.

Digital Remote Mini-Control or CAR

V2

or On/

Off chrono-thermostat electrical connections

(Optional)

.

The operations described below must

be performed after having removed the voltage

from the appliance.

Any room chrono-thermo-

stats or remote controls must be connected to

the 40 and 41 terminal blocks, eliminating the

X40 jumper (Fig. 3-2). Make sure that the On/

Off thermostat contact is of the “clean” type, i.e.

independent of the mains voltage, otherwise the

P.C.B. would be damaged. The boiler can only be

connected to one device at a time.

Important:

if the Mini CRD or CAR

V2

remote

control is used, arrange two separate lines in

compliance with current regulations regarding

electrical systems. No boiler pipes must ever be

used to earth the electric system or telephone li-

nes. Ensure elimination of this risk before making

the boiler electrical connections.

Summary of Contents for EOLO STAR 24 5E

Page 1: ...EOLO STAR 24 5E IE Instructions and warning book 1 040471ENG ...

Page 2: ......

Page 33: ......

Page 34: ......

Page 35: ......