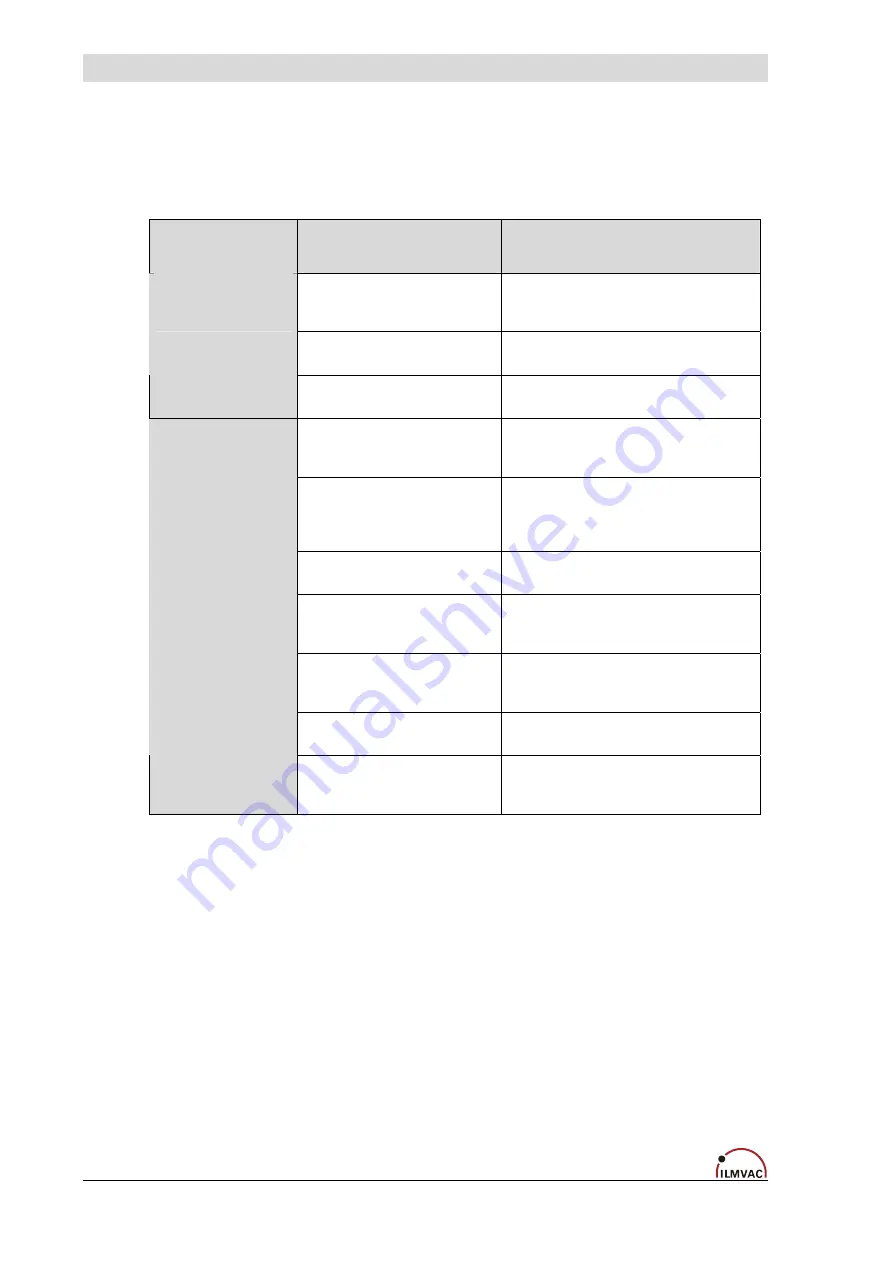

Troubleshooting

7 Troubleshooting

During the warranty period, intervention in the safety aspiration-system and accessory

components may only be made by ILMVAC GmbH and or authorised workshops.

Trouble

Cause

Remedy

No power supply to the motor

Electrical system to be checked

by a qualified electrician.

Motor defective

Exchange by service shop.

Diaphragm pump

does not start

Pump body defective

Repair by service shop.

Connected apparatus leaks,

connecting elements leak

Identify and seal the leak, replace the

seals and hoses if necessary.

Diaphragm pump leaks

(pipes or hoses)

Check the hose connections between

the pump heads, replace the hoses and

screwed clamping rings if necessary.

Pump head

Repair by service shop.

Diaphragm defective

Repair by the service workshop

or the user.

Valves are dirty

Clean condensates and foreign

objects out of the valves.

Valves defective

Replace valves.

The diaphragm

pump does not

generate a

vacuum or only

an inadequate

one.

Diaphragm pump is dirty

Cleaning by the service workshop

or the user.

16 112012