-8-

www.igmtools.com

Tail stock knob

Pic. 36

Tail stock handle

Pic. 37

6.2 Cleaning the machine

Remove the rust protection grease with

benzine or a similar solvent. It is important that

you remove all the grease and re-lubricate

with a Teflon-based lubricant. (Teflon has a

lower tendency to attract sawdust and cause

clogging).

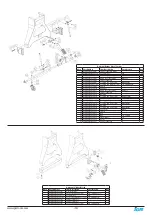

6.3 Fitting the rotating centre

Ensure that the bore of the tail stock is clean.

The rotating centre has a number 2 Morse

Taper that fits into the tail stock. Push the

centre into the tail stock bore firmly, and ensure

that it is securely located. To remove the centre,

rotate the adjusting handle until it is as far back

as possible and this will eject the centre.

Pic. 38

6.4 Fitting the drive centre into head stock

To remove the face plate from the head stock

spindle, insert the removal tool into the hole in

the face plate large diameter. Lock the spindle

with the lathe spindle lock and unlock the face

plate by rotating it. Take care not to drop the

faceplate onto the bed of the lathe.

Note: The face plate has a left-hand thread.

Removal tool

Pic. 39

described procedure, seek professional

assistance. Fit the 4 levelling feet to the lathe

legs with the lock nut on the underside of the

leg. Once both legs have been fitted turn the

assembly up to the correct position.

Pic. 29

Pic. 30

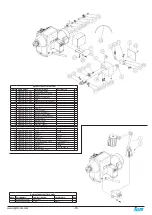

Assemble the head stock, tool rest and tail

stock back onto the bed of the lathe and

fit

the stops

.

Note

: If you have any doubt about

the described procedure, seek professional

assistance. Do not attempt any procedure that

you feel is unsafe, or that you do not have the

physical capability of achieving.

Assembled lathe

Pic. 31

If you decide to fit the tool rest after fitting the

tail stock, follow the below procedure.

Fit the tool rest onto the bed of the lathe

ensuring that the washer recess fits into the

slot in the bed. Fit the banjo onto the bed with

the bolt through the washer and assemble

the nut onto the thread. Adjust the nut so

that the clamp handle locks the banjo with

approximately 30 degree of movement.

Tool rest disassembled

Pic. 32

Pic. 33

Washer assembled in position

Pic. 34

Pic. 35

Fitting the stock knob

Screw the tail stock knob onto the tail stock

handle.

washer

Tool rest clamp handle

Banjo

clamp

handle

Rotating centre

Adjusting

handle

Levelling foot

Summary of Contents for LAGUNA 2436

Page 2: ...2 www igmtools com...

Page 12: ...12 www igmtools com Electrical drawing Wiring diagram for control panel on headstock...

Page 13: ...13 www igmtools com Exploded view drawings and parts list Wiring diagram for remote control...

Page 14: ...14 www igmtools com...

Page 20: ...20 www igmtools com...

Page 21: ...21 www igmtools com...