This sequence first indicates

if the zero operation passed

or failed, then the new

detector reading then the

option to end and return to

the engineer menu. This

sequence effectively allows

the engineer to observe the

new detector zero point

before exiting.

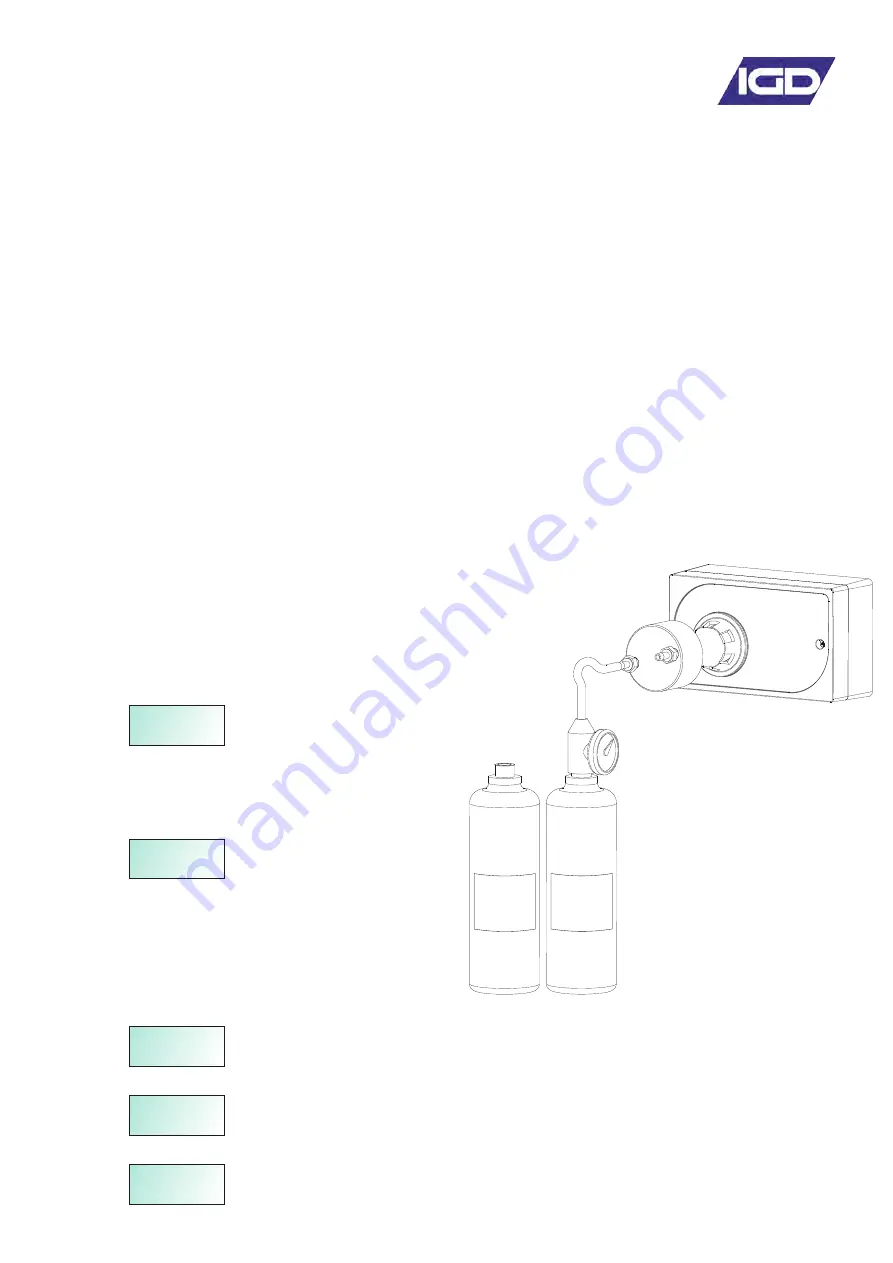

Bottled Nitrogen or Instrument grade zero air

Regulator to deliver a

fixed flowrate (typically

between 0.5 to 1 L/min)

Hose delivers zero gas to the

detector. Note a test gas

applicator is usually required.

In some cases weather

protection guards or the

detector itself may include a

gas applicator port. If not the

correct calibration gas

adaptor must be used.

Gas Detector ZERO Function

Detectors should always be zeroed first and then calibrated. Alarms should be isolated during this process. A

normal calibration sequence would consist of:

Do not rely on the ambient environment to provide a zero point, Nitrogen or Instrument air should always be used

as appropriate. If there is a background level of the target gas and a zero is performed then the zero point will not

be correctly set.

5. Apply a known calibration gas and calibrate the channel, observe and record the result.

2. Assess calibration point by applying a known calibration gas. and record

3. If the zero and calibration points are /-2% of range then take no further action. zeroing and calibrating a

detector that already reads correctly will not improve its performance. If either is out then proceed to step 4.

4. Apply a suitable zero gas and zero the channel, observe and record result.

Notes

All gas detectors will require periodic ZERO and CALIBRATION. The calibration interval depends on a number of

environmental factors such as: temperature variance, exposure to wind chill, rain, humidity changes and vibration

to list a few. As a guide line gas detectors should be checked at least yearly. As with any measuring instrument if

calibration is not held over the intervening interval then a shorter calibration interval may be required.

1. Assess zero reading in pre-zero condition and record by applying a zero gas typically Nitrogen or Instrument air

Select menu item 1 ZERO

To Zero the detector enter password mode

as previously described and enter

password 100 to enter the user menu.

The top line of the display shows the

current reading. The bottom line shows the

current option.

With zero gas flowing and the reading stable

press the button to select CONTINUE. Now

press and hold the button until prompted to

release to action the zero request.

zero

1 of 10

8 PPM

Abort

0 PPM

Continue

ZERO

PASSED

0 PPM

CLICK TO

The display shows the result of the zero request, note that the actual zero and

calibration values are stored on the individual detector heads. When carrying out a

zero or calibration the controller sends the request to the detector head for action

and monitors the result. This means that detectors can be supplied pre-calibrated

The reading is now displayed so the result of the zero request can be observed.

The reading should be stable. Click the button to return to the previous menu.

Repeat the sequence if you are not /-2% of zero.

Calibration

Zero

Gas

Gas

20% LEL