I N S T A L L A T I O N

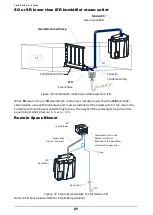

Alarm

contact

Oper.

contact

Fill

Valve 1

Drain

pump

24VAC-1

Hi

li

m

it

R

H

%

sw

itc

h

Ai

r p

ro

vi

ng

sw

itc

h

24VAC-2

Hi Limit

switch

Enable

Contact

Air Flow

Switch

Analog

input

RH analog

input

O

pt

io

na

l E

na

bl

e

co

nt

ac

t

O

pt

io

na

l o

ut

si

de

p

ow

er

so

ur

ce

fo

r H

i L

im

it

O

pt

io

na

l o

ut

si

de

p

ow

er

so

ur

ce

fo

r e

na

bl

e

co

nt

ac

t

O

pt

io

na

l o

ut

sid

e

po

w

er

so

ur

ce

fo

r A

PS

Ex

te

rn

al

a

na

lo

g

si

gn

al

fo

r d

em

an

d

o

r

ex

te

rn

al

se

tp

oi

nt

si

gn

al

24

Va

c

ou

tp

ut

–

2

A

m

ax

24

Va

c

G

nd

RH

%

si

gn

al

RH%

sensor

Or Temp.

sensor

DI2

DI1

DI3

AI1

AI2

Common

Norm Open contact

Norm Close contact

Common

Norm Open contact

Norm Close contact

- +

- +

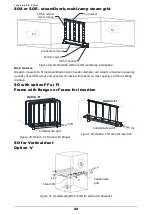

E- PCBA-001, v3.1

Main controller PCB assembly

PWM

sp

SSR

sp

Output

PT1000

2

ADC sp

PT 1000 -1

Foam

Water level

Fan

SSR

Contactor

-

+

RH%

sensor

Op onal Duct RH% sensor

for propor onal Hi lImit

Op onal propor onal output feedback

analog signal

+ -

RS485

A+

B-

+ -

AI3

Gnd

BACnet or

Modbus

Figure 42, Control connec ons

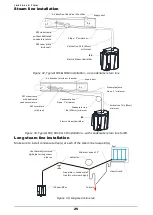

Admissible control signal

Control

Admissible signals

External analog signal for demand

0-10Vdc, 2-10Vdc, 4-20mA

On-Off external signal

Dry contact

Propor onal RH% or temperature sensor 0-10Vdc, 2-10Vdc, 4-20mA

Remote BAS control

Modbus (supplied standard) – refer to Modbus tables

BACnet MS/TP (op onal) – refer to BACnet PICS

Installation steps :

1. Ensure that the safety contact for Air proving switch and Hi limit humidistat are connected

to the terminals 4 and 5.

2. Connect the applicable controls according to the above wiring diagram

3. Selec on of control signal is done through set-up screens once the

IER

will be powered.

31

Summary of Contents for steamOvap

Page 2: ......