12

INSTALLATION

combination boiler -

Installation and Servicing

9

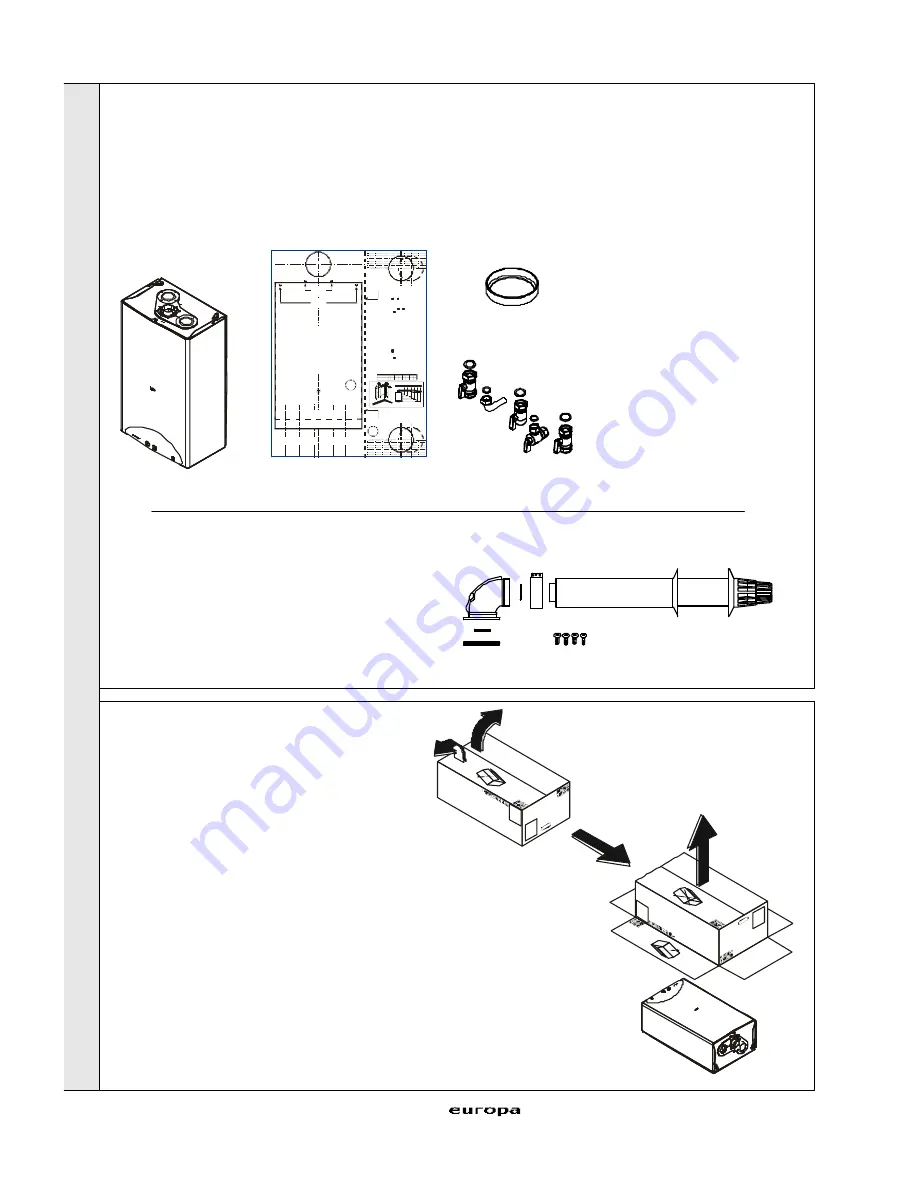

UNPACKING

The boiler is supplied fully assembled in one Pack A, together

with a standard flue assembly for lengths up to 720 mm, rear

or side flue outlet, in Pack B.

Optional extras, if ordered, are available in separate boxes.

Unpack and check the contents.

Hardware Pack

?

Wall plugs with hook screw - 2 off.

?

Wall mounting template - 1 off.

?

CH Flow and Return isolating valve

- 2 off.

?

CW inlet isolating valve - 1 off.

?

HW outlet pipe - 1 off.

?

Gas isolating valve - 1 off.

?

3/4” gaskets - 3 off.

?

1/2” gaskets - 2 off.

?

Smoke outlet diaphragm - 1 off.

?

Instructions for mounting flue

restrictor

Pack A Contents

Also contained in Pack A:

?

Hardware Pack (listed below).

?

These Installation & Servicing Instructions.

?

The User's Instructions.

?

Benchmark book.

1.

Ensure the boiler is positioned correctly as marked

on the carton (reverse position).

2.

Remove the band and staples.

3.

Fold back the top flaps and the plastic bag to get

access to the boiler.

4.

Reverse the carton on the side where top flap has

been folded to 270° (The other top flaps can be

folded to 180° only).

5.

Lift the card board box.

6.

Dispose of packaging.

7.

Remove the plastic bag and collect instructions and

read them thoroughly before installing the boiler.

1 0 PACKAGING REMOVAL

Pack B Contents

1- Flue turret.

2- Flue terminal.

3- External rubber ring.

4- Internal rubber ring.

5- Gasket for turret flange.

6- Gasket for inner pipe - 2 off.

7- Self tapping screws - 4 off.

8- Sleeve with clamp for ext. pipe - 1 off.

Instructions.

1

2

3

Complete boiler

Piping kit

Wall mounting template

Flue restrictor

1

2

3

4

5

6

6 8

7

L

L

MIN. INSTALLED TOP CLEARANCE 165 mm

TOP OF BOILER

PLEASE NOTE THE FOLLOWING POINTS

THIS TEMPLATE ( A AND B ) SHOWS THE POSITION FOR THE

FIXING HOLES AND FLUE HOLE CENTRE FOR STANDARD

INSTALLATION AND FOR USING THE OPTIONAL STAND-OFF KIT.

1. SEPARATE TEMPLATES A AND B ALONG THE DOTTED LINE.

2. TAPE TEMPLATE A INTO SELECTED POSITION.

3. ENSURE SQUARENESS BY HANGING A PLUMBLINE. IF FITTING

A SIDE EXIT FLUE THEN REFER TO SIDE EXIT INSTRUCTIONS

BELOW.

4. MARK ON THE WALL THE FOLLOWING:

a. THE TWO MOUNTING PLATE SCREW POSITIONS .

b.

THE POSITION OF THE FLUE DUCT HOLE. MARKING ON THE

CENTRE OF THE HOLE AS WELL AS THE CIRCUMFERENCE.

5. REMOVE TEMPLATE FROM THE WALL.

1. FOLLOW POINTS 1 - 3 ABOVE:

2. EXTEND FLUE CENTRE LINE HORIZONTALLY ACROSS SIDE

WALL THEN HORIZONTALLY FORWARD, AS SHOWN.

3. FOR HEIGHT OF FLUE HOLE, LOWER HORIZONTAL CENTRELINE

OF TEMPLATE B DOWN BY AN AMOUNT DEPENDING ON

THE SIDE CLEARANCE BETWEEN BOILER AND SIDE WALL, AS

SHOWN IN TABLE BELOW.

4. TAPE TEMPLATE B INTO SELECTED POSITION.

5. MARK ON THE CENTRE OF THE FLUE HOLE AS WELL AS THE

CIRCUMFERENCE.

6. IF USING THE OPTIONAL STAND-OFF KIT FOR UPWARD

PIPING MARK ON THE HOLE CENTRE AND CIRCUMFERENCE

OF THE DASHED CIRCLE.

7. PROCEED TO POINT 4 ABOVE:

TEMPLATE INSTRUCTIONS

INSTRUCTIONS FOR RH & LH SIDE EXIT FLUE

For mounting

Stand-off kit

WITHOUT

MIN. INSTALLED CLEARANCE FOR ACCESS

TO LOWER CONTROLS - 150 mm

OF 28 kW BOILER

BOTTOM

SI

D

E

O

F

BO

IL

ER

(

MIN

. S

IDE

CL

EA

R

AN

CE

1

5 m

m)

S

ID

E

O

F

BO

IL

ER

(

MI

N.

SID

E C

LE

A

RA

NC

E

15

m

m)

L

L

L

c

c

c

c

c

OFFSET AT 15 mm MIN CLEARANCE

OF

F SE

T

A T 1

5

mm

M

I N

C

L EA

RAN

CE

OFFSET FOR 0.5 m FLUE

OFF

SET

F

OR

0.

5

m F

L UE

OFFSET FOR 1 m FLUE

OFF

SET

F

OR

1

m F

L UE

OFFSET FOR 1.5 m FLUE

OFF

SET

F

OR

1.

5

m F

L UE

OFFSET FOR 2 m FLUE

OFF

SET

F

OR

2

m F

L UE

OFFSET FOR 2.5 m FLUE

OFF

SET

F

OR

2.

5

m F

L UE

OFFSET FOR 3 m FLUE

OFF

SET

F

OR

3

m F

L UE

R.H. FLUE OUTLET

WALL MOUNTING TEMPLATE

L.H

. F

LU

E O

U TL

ET

W AL

L

M OU

N TIN

G TE

M PL

ATE

C

UT

AL

O

NG

D

OT

TE

D

LIN

E

CORNER OF WALL

FOR R.H. OUTLET

C OR

N ER

O

F W

ALL

FO

R L.

H . O

U TL

ET

A

B

For mounting

Stand-off kit

WITH

FLUE DUCT DOWNWARD

OFFSET DIMENSIONS

1 3 m m 26 mm

3 9 m m 5 2 m m

6 5 m m

7

8

m

m

5 mm

BOILER TO SIDE

WALL CLEARANCE

0.5 m

1.0 m

1.5 m

2 m 2.5 m

3 m

15 mm

12

7 m

m D

I A.

C

I RC

LE

(

5 ”)

CENTRAL

HEATING

FLOW

DHW

(HOT)

OUTLET

GAS

INLET

DHW

(COLD)

INLET

CENTRAL

HEATING

R E T U R N

127 mm DIA. CIRCLE (5”)

00331388

1 .

2 .

3 .

4 .

5 .

6 .

WALL MOUNTING TEMPLATE

ATTENTION !

THIS BOILER HAS A COPPER HEAT EXCHANGER.

APPROPRIATE WATER TREATMENT MUST BE USED

THE FLUE TERMINAL POSITION IS IN THE CENTRE OF THE

BOILER. USE SHOULD BE MADE OF THIS TEMPLATE & DUE

NOTE TAKEN OF THE POSITION OF THE TERMINAL ON THE

OUTSIDE WALL. FOR VERTICAL AND TWIN FLUE APPLICATIONS

REFER TO THE INSTALLATION INSTRUCTIONS.

THE BOILER SETTING PRESSURE IS PRE-SET DURING

MANIFACTURE. IN CASE OF DIFFICULTY, PLEASE ENSURE

ADEQUATE INLET PRESSURE OF 20 mbar NATURAL GAS.

THE GAS SUPPLY PIPEWORK TO THE BOILER SHOULD

BE A MINIMUM 22 mm DIAMETER COPPER.

FOR CORRECT OPERATION OF THE BOILER IGN ITION

SEQUENCE, ELECTRICAL POLARITY MUST BE CORRECT.

REFER TO INSTALLATION INSTRUCTIONS FOR ELECTRICAL

CONNECTIONS AND SYSTEM WIRING DIAGRAM.

THE BOILER IS SUITABLE FOR PUMPED CIRCUITS ONLY.

GRAVITY CIRCUITS MUST NOT BE USED. USE 22 mm

PIPEWORK FOR ON FLOW AND RETURN CONNECTIONS

IF THE BOILER IS TO BE LEFT SWITCHED OFF AFTER

COMMISSIONING DUE CARE MUST BE TAKEN TO AVOID

FREEZING.

PLEASE NOTE THE POINTS BELOW AND RIGHT

MIN. INSTALLED CLEARANCE FOR ACCESS

TO LOWER CONTROLS - 150 mm

OF 24 kW BOILER

BOTTOM

127 mm DIA. CIRCLE (5”)

Flue duct hole

o f f s e t V ( m m )

1 3

0.

5

2 6

3 9

5 2

6 5

See wall mounting plate

7 8

1

1.5

2

2.5

3

Distance in metres from side of boiler wall H (m)

H

V

INSTALLATION