8

Classic LX, RS -

Installation

GENERAL

IMPORTANT.

It is absolutely ESSENTIAL to ensure, in practice,

that products of combustion discharging from the terminal

cannot re-enter the building or any other adjacent building

through ventilators, windows, doors, other sources of natural air

infiltration or forced ventilation/air conditioning.

If this should occur, the appliance MUST be turned OFF,

labelled 'unsafe' and corrective action taken.

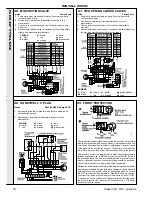

TERMINAL

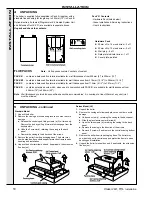

The terminal assembly can be adapted to accommodate various

wall thicknesses. Refer to Frame 4 - Unpacking.

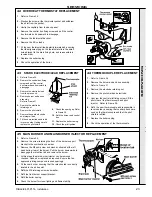

AIR SUPPLY

Detailed recommendations for air supply are given in

BS.5440:2. The following notes are for general guidance:

1.

It is NOT necessary to have a purpose provided air vent in

the room or internal space in which the boiler is installed.

2.

If the boiler is to be installed in a cupboard or compartment,

permanent air vents are required (for cooling purposes) in

the cupboard/compartment, at both high and low levels. The

air vents must either communicate with room/internal space,

or be direct to outside air. The minimum effective areas of

the permanent air vents, required in the cupboard/

compartment, are specified as follows and are related to

maximum rated heat input.

3.

Both air vents MUST communicate with the same room or

internal space or MUST be on the same wall to outside air.

4.

In siting the air vents care must be taken to avoid the

freezing of pipework.

Table 4 - High and low vent areas

WATER CIRCULATION SYSTEM

The boiler must NOT be used for direct hot water supply. For

the types of system and correct piping procedure refer to

'Introduction' and Frame 1.

The central heating system should be in accordance with

BS. 6798 and, in addition, for smallbore and microbore

systems, BS. 5449.

The domestic hot water system, if applicable, should be in

accordance with the relevant recommendations of BS. 5546.

Copper tubing to BS. 2871:1 is recommended for water carrying

pipework.

The hot water storage cylinder MUST be of the indirect type

and should preferably be manufactured of copper.

Single feed, indirect cylinders are not recommended and MUST

NOT be used on sealed systems.

THERMOSTATIC RADIATOR VALVES

Caradon Plumbing Limited

recommend that heating systems

utilising full thermostatic radiator valve control of temperature in

individual rooms should also be fitted with a room thermostat

controlling the temperature in a space served by radiators not

fitted with such a valve, as stated in BS. 5449.

When thermostatic radiator valves are used, the space heating

temperature control over a living / dining area or hallway having

a heating requirement of at least 10% of the boiler heat output

should be achieved using a room thermostat, whilst other rooms

are individually controlled by thermostatic radiator valves.

However, if the system employs thermostatic radiator valves on

all radiators, or two port valves without end switches then a

bypass must be fitted in order to ensure a flow of water should

all the valves be in the closed position.

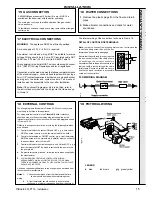

ELECTRICAL SUPPLY

Wiring external to the appliance MUST be in accordance with

the current I.E.E. (BS. 7671) Wiring Regulations and any local

regulations which apply.

The point of connection to the mains should be readily

accessible and adjacent to the boiler, except for bathroom

installations; the point of connection to the mains MUST be

situated outside of the bathroom.

Note.

Where a room sealed appliance is installed in a room containing

a bath or shower then the appliance and any electrical switch or

appliance control utilising mains electricity should be so situated

that it cannot be touched by a person using the bath or shower.

The hot water cylinder and ancillary pipework not forming part of

the useful heating surface should be lagged to prevent heat loss

and any possible freezing - particularly where pipes run through

roof spaces and ventilated underfloor spaces.

IMPORTANT.

The boiler must be vented

(not on sealed systems.)

Draining taps MUST be located in accessible positions, which

permit the draining of the whole system - including the boiler and

hot water storage vessel. They should be at least 1/2" BSP

nominal size and be in accordance with BS. 2879.

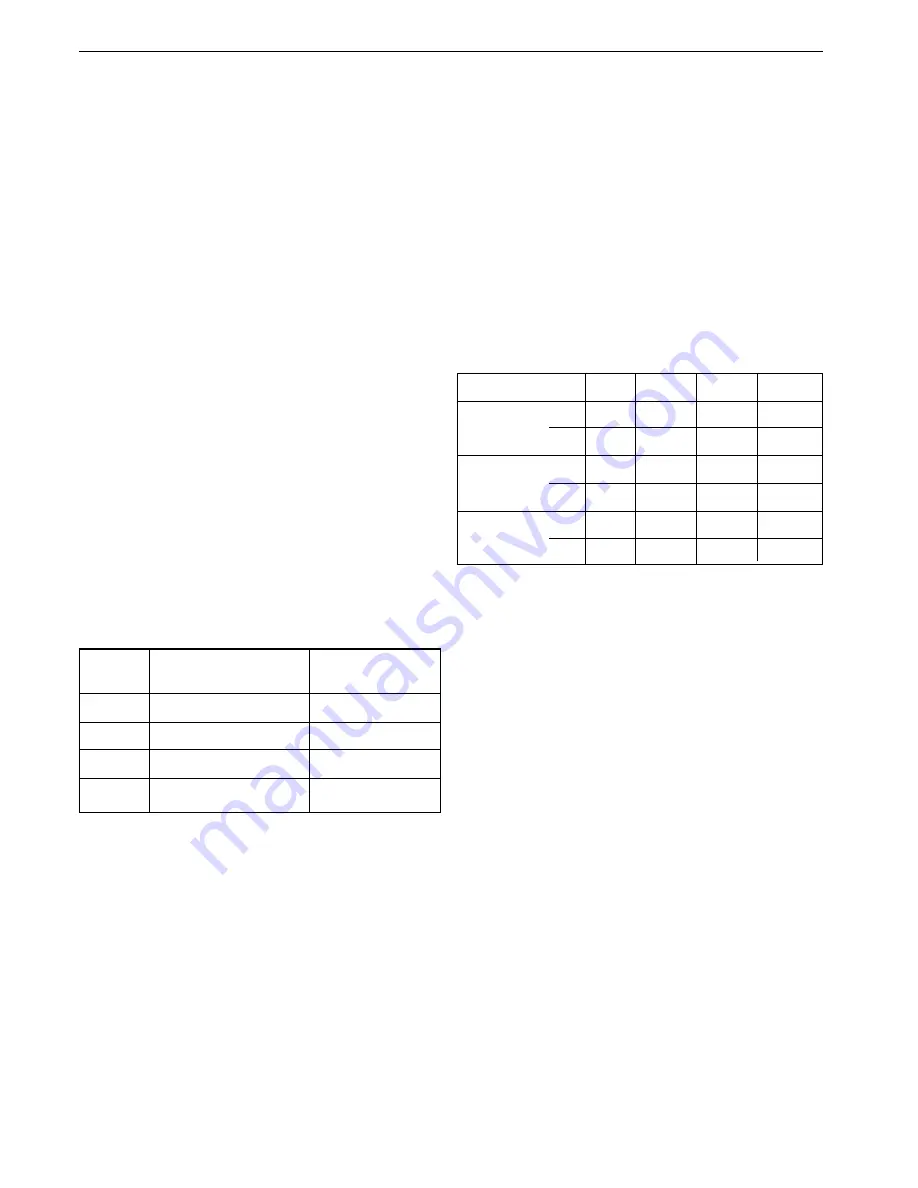

The boiler is fitted with a special drain plug (provided) to drain

the BOILER ONLY, in the event of the system drain plug being

unable to do so. The hydraulic resistance of the boilers, at

MAXIMUM OUTPUT with an 11

0

C (20

0

F) temperature

differential, are shown in Table 5.

Table 5 - Water flow rate and pressure loss

Boiler Size

RS230

RS240

RS250

RS260

Boiler

kW

8.8

11.7

14.7

17.6

Output

Btu/h 30 000

40 000

50 000

60 000

Water flow

l/min

11.4

15.2

19.0

22.8

Rate

gal/h

150

200

250

300

Pressure

mbar

24.0

22.0

34.0

45.0

Loss

in wg

9.6

9.0

13.6

18.0

Boiler

Air from room/internal

Air direct

Space cm

2

(in.

2

)

Outside cm

2

(in.

2

)

RS230

102 (16)

51 (8)

RS240

135 (21)

68 (11)

RS250

170 (26)

83 (13)

RS260

198 (31)

102 (16)

Summary of Contents for Classic LXRS 230

Page 1: ......