7

Plate Heat Exchanger Package

Section 4 - Installation Requirements

4.1 INSTALLATION AREA AND

DIMENSIONS

Ensure adequate access for boiler and package installation.

Ensure at least 450 mm clearance from the front of the

appliance to allow servicing.

The condensate drain must have a 1 in 20 fall away from the

appliance.

Adequate room above the boilers must allow the installation

and serving of the boiler flue system. Further information

concerning flue and condensate drain connection can be

found in the boiler installation manual.

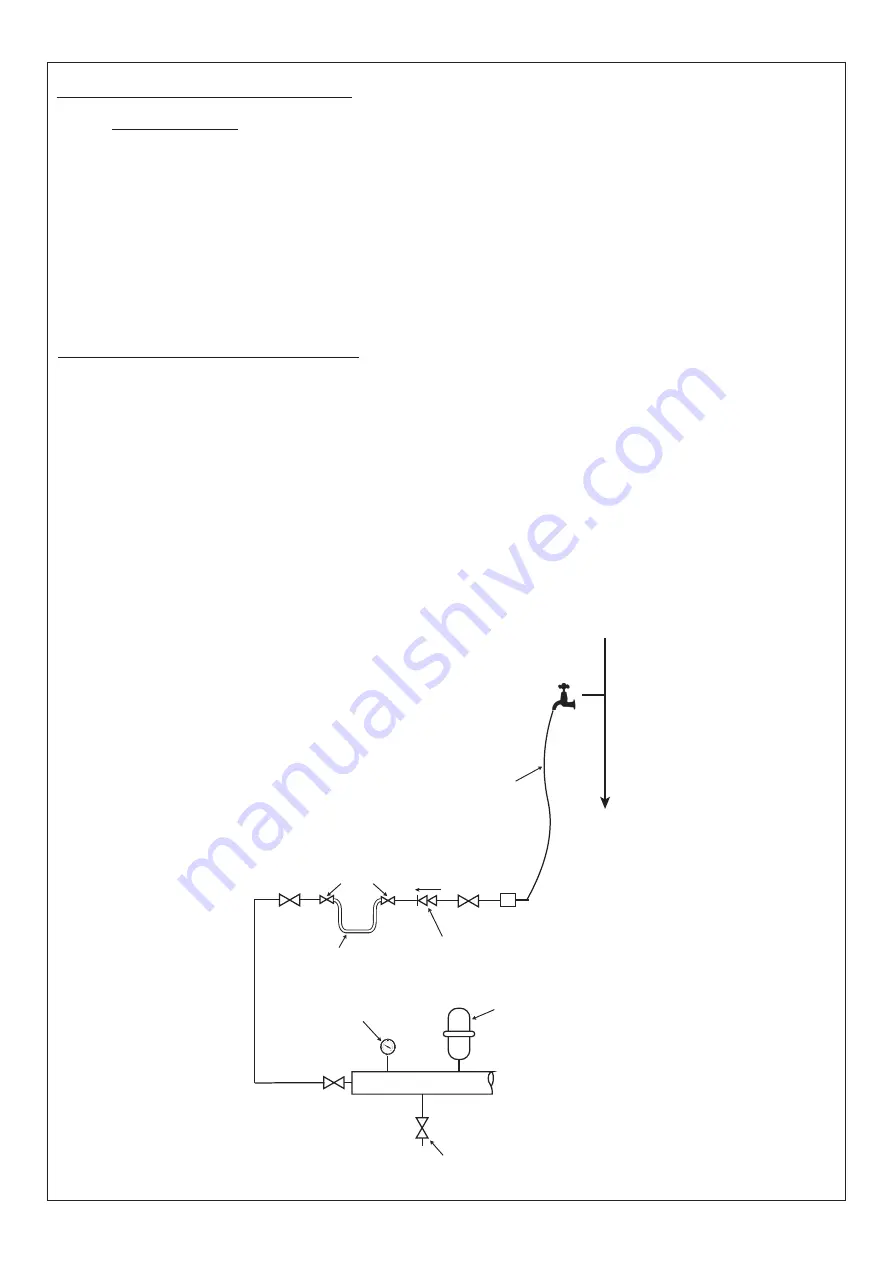

4.2 SYSTEM REQUIREMENTS

1.

Ancillary components can be connected to the system via

the G3/4” isolation valve on the boiler return pipework.

See diagram below for guidance (diagram for illustration

purposes only).

2.

The method of filling, refilling, topping up or flushing

sealed primary circuits from the mains via a temporary

hose connection is only allowed if acceptable to the local

water authority.

3.

The filling device must be connected to comply with the

water regulations, as shown below. This may involve fitting

an a suitable WRAS approved isolator valve to the mains

supply and appropriate backflow prevention device.

Pressure relief valve (Supplied with the package)

Pressure Gauge

Expansion Vessel

Drain Cock

Return

Double check valve or

RPZ assembly

(note direction of flow)

Additional

stop valve

Hosepipe

(disconnect

after filling)

Water

Supply

Temporary Hose

(disconnect

after filling)

Hose unions

G3/4”

Valve

4.

A spring-loaded non-adjustable 3 bar pressure relief valve

complying with the relevant standards of BS6759 Pt1

is fitted close to the boiler with no intervening valve or

restriction.

5.

A manual testing device.

6. The safety valve outlet should be piped to ensure water or

steam discharge cannot create a hazard to personnel or

damage electrical components or wiring.

Pressure gauge (Supplied with the package)

A pressure gauge covering at least 0-6 bar is fitted to the

return pipework, visible from the filling point.

Expansion vessel (Supplied with the package)

7. A diaphragm type expansion vessel complying with BS.

EN 13831 must be fitted, with a valve in the normally open

positioned protected using a lockshield from unauthorised

closure.

8. The vessel capacity must be adequate to accept the

expansion of system water when heated to 85 °C.

9. The charge pressure must not be less than the static

water head above the vessel. The pressure attained in the

system when heated to 85 °C should be at least 0.35 bar

less than the lift pressure of the pressure relief valve.

The 4L expansion vessel supplied is suitable for all

appliances.

System drain cock (Supplied with the package)

A drain cock is fitted to the lowest section of the return

pipework. A second drain cock is fitted above the NRV after

the boiler pump.