6

Polyset Kit Storage and Re-Use

1. Close cylinder valves.

2. Do not store full cylinders at temperatures above 100°F (38°C). Do not store partial or used cylinders above 90°F (32°C) or below 50°F (10°C). Kits stored

below 70°F must be given sufficient time for the chemical to warm up to 70–85°F (21–29°C), see TDS for formula specific temperature recommendations.

3. The used nozzle should be left on the dispensing unit during storage in order to help keep the outlet ports of the dispensing unit clean and free from any dust,

dirt or chemical that can affect the proper sealing of the nozzle. SAFETY: Always engage the trigger safety and close all supply valves during storage.

4. All dispensing unit nozzles are easily cleanable and solvent resistant. To clean nozzles, liquid chemical must be dissolved prior to it’s complete chemical

reaction by flushing the nozzle with a suitable solvent such as Polysolv. Gun face can be kept clean with the use of petroleum jelly on the face or with a soft

cloth to remove residue.

5. DO NOT REMOVE HOSES FROM CYLINDERS.

Keep under pressure. Do not flush/clean hoses with air, water or solvent. Removing and/or cleaning hoses

may compromise the adhesive.

To reuse dispensing unit after storage:

1. Remove the used nozzle.

2. Check the face of the dispensing unit to make sure the outlet ports are clear and the face of the unit is free from dirt, chemical or other debris. If

necessary, use a soft cloth or rag to remove any cured adhesive or chemical from the face of the dispensing unit. Use of enclosed petroleum jelly is

recommended to cover the face of the unit in order to prevent further contamination or if chemical is accidentally leaked into this area.

3. Shake kit or cylinders for 1-2 minutes to ensure proper mixing. Polyset CR-20 adhesive should be between 70˚- 90˚F (21˚-32˚C). Polyset Board-Max

adhesive should be between 70˚- 85˚F (21˚-29˚C). See TDS for formula specific shaking and temperature recommendations.

4. Fully open all cylinder valves.

5. Dispense into waste containter to verify that both chemicals are being dispensed in approximately equal streams. The dispensing unit is a disposable

unit not designed for prolonged storage or continuous re-use. To help extend the storage life, it is recommended to dispense a minimal amount of

adhesive from unit at least once every three (3) days to ensure optimum flow of chemical through hoses. Use of contents within 30 days of initial use is

recommended.

VERY IMPORTANT:

As the hoses are exposed to the heat of the sun, especially in the summer months, the pressure in the hoses will build up. Purging the hoses

for a few seconds prior to spraying relieves the excess pressure and allows the chemical to flow in the proper proportions.

1. DO NOT INCINERATE TANKS.

2. Use proper Personal Protective Equipment when disposing of cylinders.

3. Dispense the adhesive into a waste container like a cardboard box or plastic bag. Depressurize the used cylinders using the dispensing unit with a new

nozzle attached. Spray the adhesive until one of the components/cylinders no longer sprays chemical.

4. Remove the nozzle and then continue to depressurize by dispensing the chemicals into a waste container (a box lined with a plastic bag) that has adequate

industrial liquid absorbing medium in the bottom. Dispense the residual chemicals until the pressure is down to a minimum or there are just large bubbles in

the hose.

5. Close the cylinder valves completely, and then operate the dispensing unit again to empty and depressurize the hoses. Use a 9/16” wrench and remove the

hoses from the cylinders. Use caution in case there is some residual chemical and/or pressure in the hoses.

6. Invert the cylinder and point away from face. Slowly open the cylinder over the waste container to catch any residual spray.

7. Return the cylinder to an upright position. Shake the container; there should not be any sloshing of liquid. Make sure to leave valves OPEN -do not close.

8. DISPOSE OF EMPTY CYLINDERS ACCORDING TO APPLICABLE FEDERAL, STATE, AND LOCAL REGULATIONS. CHECK WITH YOUR LOCAL WASTE

DISPOSAL SERVICE FOR GUIDANCE.

NOTE:

After dispensing if one cylinder has chemical left in it; treat as hazardous material.

Disposal Procedures

Troubleshooting Guide

Equivalent flow of both A-component and B-component is required with all two-component polyurethane systems in order to obtain proper performance, curing

and optimum yields. If a problem occurs, the cause is typically due to uneven chemical flow that is caused by a blockage of one of the chemicals.*

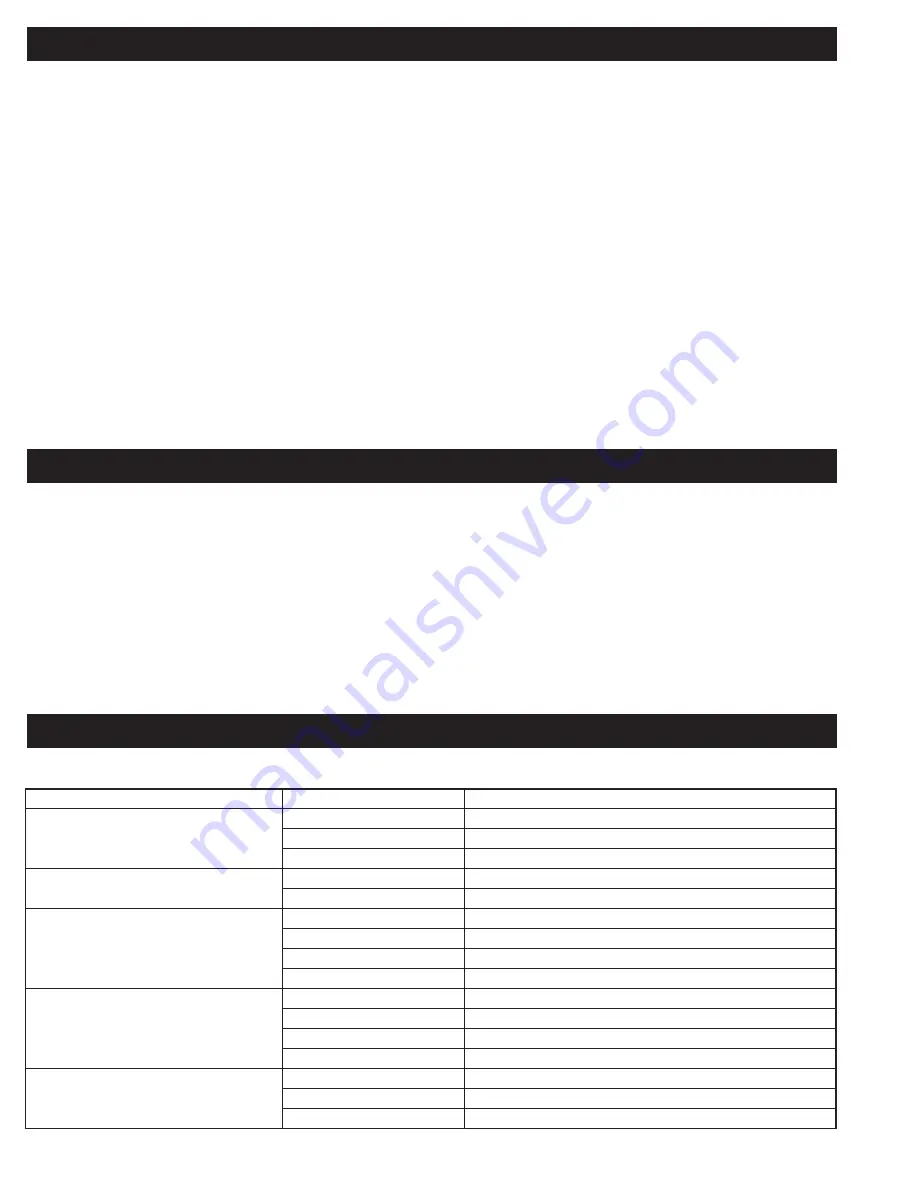

PROBLEM

POSSIBLE CAUSE

SOLUTION

Poor chemical flow

Cylinder valves not fully open

Turn cylinder valves counter-clockwise until they stop

Cylinder valves in incorrect position

Place cylinder valves in upright position

Material is too cold

Chemical temperature must be between 70˚- 85˚F (21˚-29˚C)**

Adhesive leaking from hose connections

Hoses not tightened

Tighten all hose fittings

Cross-threaded hose

Replace gun hose assembly

Dark crunchy adhesive/ off-ratio (A-rich)

Material is too cold

Chemical temperature must be between 70˚- 85˚F (21˚-29˚C)**

Clogged nozzle

Replace nozzle

Blockage of one chemical port

Clean gun face and apply petroleum jelly

Gun crossover

Replace hose

White spongy or shrinking adhesive/off-ratio (B-rich)

Material is too cold

Chemical temperature must be between 70˚- 85˚F (21˚-29˚C)**

Clogged nozzle

Replace nozzle

Blockage of one chemical port

Clean gun face and apply petroleum jelly

Gun crossover

Replace hose

Sputtering from nozzle

Cylinders are empty

Switch to new kit

Clogged nozzle

Replace nozzle

Hose blockage

Replace hose

*If kit is still not fully operational, stop spraying and contact the distributor where purchased.

**See TDS for specific temperature recommendations.