12

9. After all the set up procedures mentioned above have

been completed, the burner should be fired and an

inspection mirror should be used to observe the flame

pattern at the tip of the nozzle. Any irregularities such as

burning to one side or pulsating flame patterns should

be corrected by changing the nozzle.

2.3)

FAN ADJUSTMENT CHECK

Adjust the fan speed ACCORDING TO THE OIL INPUT

SELECTED, so that the temperature rise is within the one

specified on the Rating Plate (see Table 3). Consult the

wiring diagram for speed changes on the direct drive motor.

To adjust the fan “OFF” time, set the DIP switches on the

control board to the desired timing as per Figure 9.

FIGURE 9

Adjustment of “OFF” settings

2.4)

LIMIT CONTROL CHECK

After the furnace has been in operation for at least 15

minutes, restrict the return air supply by blocking the filters or

closing the return registers and allow the furnace to shut

down on High Limit. The burner will shut OFF but the main

blower should continue to run.

Remove the restriction and the burner should come back on

in a few minutes.

2.5)

Year round air conditioning

The furnace is designed for use in conjunction with cooling

equipment, to provide year round air conditioning. The

blower has been sized for both heating and cooling,

however, the fan motor speed may need to be changed to

obtain the necessary cooling airflow.

2.6) Heating

The blower speed is factory set to deliver the required airflow

at normal duct static pressure.

2.7) Cooling

The blower speed may be adjusted in the field to deliver the

required airflow for cooling applications, as outlined in

Table 4.

2.8)

Constant Blower Switch

This furnace is equipped with a constant low speed blower

option. Whenever the room thermostat is not calling for

heating or cooling, the blower will run on low speed in order

to provide air circulation. If this constant blower option is not

desired, the rocker switch on the side of the control box can

be used to turn it off.

2.9)

SEALED COMBUSTION SYSTEM (SCS)

OPERATION

2.9.1) General

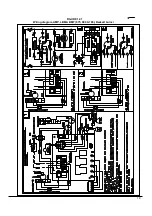

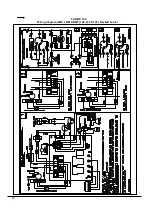

Note: Refer to the wiring diagrams, Figures 12.7 and 12.8

and the Parts List.

Normal operation

When the thermostat calls for heat, the T-T contact of the

burner Primary Control closes. After a 3 second delay, the

burner motor and igniter are activated by the Primary

Control. After a further 15 second delay the solenoid valve is

activated and ignition occurs.

When the burner blower starts, pressure is created in the

combustion chamber and a vacuum is created in the burner

casing. These pressures act on the PS-1 pressure switch

adjusted to close at 0.8” W.C.. It is important to know that the

two pressures act in the same way on the pressure switch

diaphragm.

In less than 4 seconds, the total pressure

should stabilize between 0.2" and 0.7" W.C. (see section

2.5.2).

Abnormal operation

A Sealed combustion system (SCS) incorporates a safety

shutdown feature that will shut the burner down in the

eventuality of a blocked intake or a blocked vent outlet:

1. The pressure switch PS-1 reacts if the total pressure

goes over 0.8" W.C.;

2. The TDR-1 contact closes after 4 seconds and power is

applied to the C coil of the SPDT relay;

Note:

At that point the L-1 light comes on, which is an

indication that there is a problem with the

pressure in the SCS or with the pressure

switches.

1 2 1 2 1 2 1

60 Sec. 90 Sec. 120 Sec. 150

BOUTONS

1 2

1 2

1 2

1 2

60 Sec.

90 Sec.

120 Sec.

150 Sec.

DIP switches

DNS-0377 Rev. A

Summary of Contents for AMP105-IE2

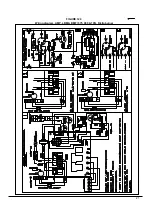

Page 20: ...FIGURE 12 1 Diagramme lectrique AMP LBM BMF 075 090 et 105 br leur Beckett 21...

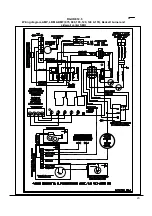

Page 21: ...FIGURE 12 2 Diagramme lectrique AMP LBM BMF 120 140 et 155 br leur Beckett 22...

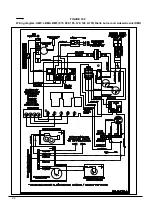

Page 22: ...FIGURE 12 3 Diagramme lectrique AMP LBM BMF 075 090 et 105 br leur Riello 23...

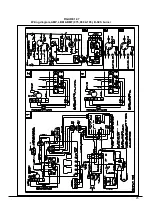

Page 23: ...FIGURE 12 4 Diagramme lectrique AMP LBM BMF 120 140 et 155 br leur Riello 24...

Page 26: ...FIGURE 12 7 Diagramme lectrique AMP LBM BMF 075 090 et 105 br leur B SCS 27...

Page 27: ...FIGURE 12 8 Diagramme lectrique AMP LBM BMF 120 140 et 155 br leur B SCS 28...

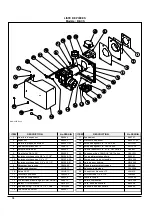

Page 28: ...29 COMPOSANTES ET PI CES DE REMPLACEMENT...

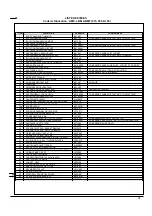

Page 29: ...LISTE DE PI CES Code de fabrication AMP LBM BMF 075 090 105 30 B50058A...

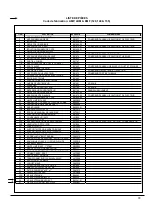

Page 31: ...LISTE DE PI CES Code de fabrication AMP LBM BMF 120 140 155 32 50062A...

Page 51: ...19 FIGURE 12 1 Wiring diagram AMP LBM BMF 075 090 105 Beckett burner...

Page 52: ...20 FIGURE 12 2 Wiring diagram AMP LBM BMF 120 140 155 Beckett burner...

Page 53: ...21 FIGURE 12 3 Wiring diagram AMP LBM BMF 075 090 105 Riello burner...

Page 54: ...22 FIGURE 12 4 Wiring diagram AMP LBM BMF 120 140 155 Riello burner...

Page 57: ...FIGURE 12 7 Wiring diagram AMP LBM BMF 075 090 105 B SCS burner 25...

Page 58: ...FIGURE 12 8 Wiring diagram AMP LBM BMF 120 140 155 B SCS burner 26...

Page 59: ...27 COMPONENTS AND REPLACEMENT PARTS...

Page 60: ...PARTS LIST Model AMP LBM BMF 075 090 105 28 B50058A...

Page 62: ...PARTS LIST Model AMP LBM BMF 120 140 155 30 B50062A...