5

When installed in a horizontal position, the furnace may be

suspended by using an angle iron frame, as long as the total

weight of both the furnace and the frame are included in the

calculations. Other methods of suspension are acceptable.

When installed in the horizontal position, this furnace must

not be installed on combustible flooring, unless the approved

sub-base is used (Model # HFB-101).

The required minimum clearances for this furnace in all

positions are specified in Tables 5.1 and 5.2.

The furnace should be located as closely as possible to the

chimney or vent in order to keep vent connections short and

direct. The furnace should also be located near the centre of

the air distribution system.

1.3.1) Air for combustion and ventilation

Chimney and SCS installation

Refer to the CAN/CSA-B139 Installation Code for complete

regulations and for guidance on retrofit applications.

This furnace should be installed in a location in which the

facilities for ventilation permit satisfactory combustion of oil,

proper venting and the maintenance of ambient

temperatures at safe limits under normal conditions of use.

The location should not interfere with the proper circulation of

air within the confined space.

When this furnace is installed in a closet or similar enclosure,

2 ventilation openings are required for combustion air. The

openings should be located about 152.4 mm (6

")

from the

top and the bottom of the enclosure at the front of the

furnace. Table 1 indicates the minimum dimensions required

for these ventilation openings.

TABLE 1

Input

(BTU/h)

Width

Height

75,000 – 105,000

0.46 m (18")

0.20 m (8")

120,000 – 155,000

0.51 m (20")

0.25 m (10")

WARNING

Do not block the combustion air openings in the

furnace. Any blockage will result in improper

combustion and may result

in a fire hazard

and/or cause bodily harm.

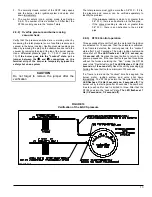

Chimney installation only

The barometric draft regulator included with the furnace,

shall be installed in the same room or enclosure as the

furnace, in such a manner as to prevent any difference in

pressure between the regulator and the combustion air

supply.

Air requirements for the operation of exhaust fans, kitchen

ventilation systems, clothes dryers, and fireplaces shall be

considered in determining the adequacy of the space to

provide combustion air requirements.

In unconfined spaces, in buildings of conventional frame,

brick or stone construction, infiltration may be adequate to

provide air for combustion, ventilation and dilution of flue

gases. This determination must be made on an individual

installation basis and must take into consideration the overall

volume of the unconfined space, the number of windows and

ventilation openings, the number of doors to the outside,

internal doors which can close off the unconfined space and

the overall air tightness of the building construction.

Many new buildings and homes (and older ones that have

been weatherized must be considered as being tight

construction and, therefore, infiltration will not be sufficient to

supply the necessary air for combustion and ventilation.

A building can be considered as being of tight construction

when:

a. Walls and ceilings exposed to the outside have a

continuous water vapour retarder with a rating of one

perm or less, openings have gaskets or are sealed

and/or;

b. Weather-stripping has been added on operable windows

and doors, and/or;

c. Caulking or sealant has been applied to areas such as

joints around window and doorframes, between sole

plates and floors, between wall-ceiling joints, between

wall panels, at penetrations for plumbing, electrical and

fuel lines and at other openings.

1.3.2) Duct

recommendations

The proper sizing of warm air ducts is necessary to ensure

satisfactory furnace operation. Ductwork should be in

accordance with the latest editions of NFPA-90A (Installation

of Air Conditioning and Ventilating Systems) and NFPA-90B

(Warm Air Heating and Air Conditioning Systems) or

Canadian equivalent.

The supply ductwork should be attached to the flanged

opening provided at the discharge end of the furnace. See

Figures 11.1 and 11.2 for the dimensions of this opening.

Knockouts are provided on both sides of the furnace to cut

the required size of opening for the installation of the return

air ductwork. This can be done on either the right or the left

side of the furnace. See Table 2 (page 10) for location and

dimensions.

NOTE:

THE BACK SHOULD

NOT

BE CUT OUT FOR

RETURN AIR DUCTING

Also, there is provision on this furnace for a bottom return air

duct. Knockouts are provided in the floor of the furnace to

facilitate the cut-out requirement for the air filter rack and

return ductwork. (We recommend the use of this opening for

horizontal and counterflow installations).

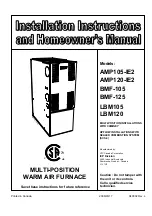

Summary of Contents for AMP105-IE2

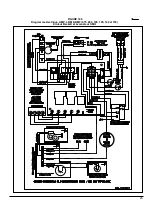

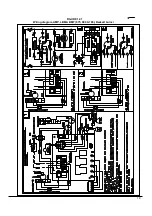

Page 20: ...FIGURE 12 1 Diagramme lectrique AMP LBM BMF 075 090 et 105 br leur Beckett 21...

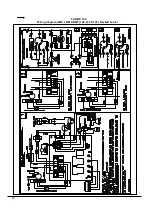

Page 21: ...FIGURE 12 2 Diagramme lectrique AMP LBM BMF 120 140 et 155 br leur Beckett 22...

Page 22: ...FIGURE 12 3 Diagramme lectrique AMP LBM BMF 075 090 et 105 br leur Riello 23...

Page 23: ...FIGURE 12 4 Diagramme lectrique AMP LBM BMF 120 140 et 155 br leur Riello 24...

Page 26: ...FIGURE 12 7 Diagramme lectrique AMP LBM BMF 075 090 et 105 br leur B SCS 27...

Page 27: ...FIGURE 12 8 Diagramme lectrique AMP LBM BMF 120 140 et 155 br leur B SCS 28...

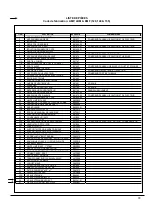

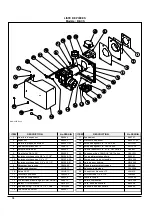

Page 28: ...29 COMPOSANTES ET PI CES DE REMPLACEMENT...

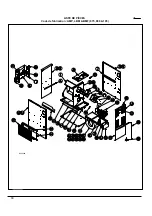

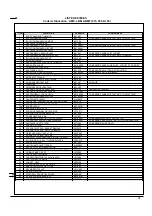

Page 29: ...LISTE DE PI CES Code de fabrication AMP LBM BMF 075 090 105 30 B50058A...

Page 31: ...LISTE DE PI CES Code de fabrication AMP LBM BMF 120 140 155 32 50062A...

Page 51: ...19 FIGURE 12 1 Wiring diagram AMP LBM BMF 075 090 105 Beckett burner...

Page 52: ...20 FIGURE 12 2 Wiring diagram AMP LBM BMF 120 140 155 Beckett burner...

Page 53: ...21 FIGURE 12 3 Wiring diagram AMP LBM BMF 075 090 105 Riello burner...

Page 54: ...22 FIGURE 12 4 Wiring diagram AMP LBM BMF 120 140 155 Riello burner...

Page 57: ...FIGURE 12 7 Wiring diagram AMP LBM BMF 075 090 105 B SCS burner 25...

Page 58: ...FIGURE 12 8 Wiring diagram AMP LBM BMF 120 140 155 B SCS burner 26...

Page 59: ...27 COMPONENTS AND REPLACEMENT PARTS...

Page 60: ...PARTS LIST Model AMP LBM BMF 075 090 105 28 B50058A...

Page 62: ...PARTS LIST Model AMP LBM BMF 120 140 155 30 B50062A...