11

PART 2

START-UP

2.1) OPERATIONAL

CHECKLIST

1=>

Has the blower wheel support been removed?

2=>

Has the electrical wiring been completed

according to Figures 12.1 to 12.8?

3=>

Has the access blower door been secured in

place?

4=>

Is the valve on the oil line open?

5=>

Has the ‘’RESET BUTTON’’ on the Primary

Control been pushed?

6=>

Is the flame observation door and the two clean-

out access doors located at the front of the unit

closed?

7=>

Is the room thermostat in the heating mode and

set above room temperature?

8=>

Set the main electrical switch to the ‘’ON’’

position and the burner should start

.

CAUTION

Do not tamper with the unit or its controls. Call a

qualified service technician.

2.2) COMBUSTION

CHECK

In order to obtain optimum performance from the oil burner,

the following set-up procedures must be followed by referring

to the Technical Specifications (Table 3) in this manual:

1. A test kit to measure the smoke, flue draft and over-fire

draft should be used in order to obtain the proper air

band setting. Although all of the above measurements

are required for optimum set up and efficiency, the most

important reading that must be taken is the smoke

number in the flue pipe or at the smoke test port on the

breech plate (SCS);

2. The proper smoke number, as established by way of

engineering tests, is between 0 and 1. This degree of

smoke emission is commonly referred to as a “trace”. It

is recommended that a Bacharach True Spot Smoke

Test kit or equivalent be used;

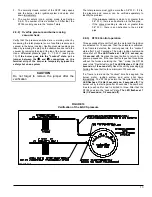

3. On chimney installations only, a barometric draft

regulator (supplied with the furnace) must be installed as

closely to the breech of the furnace as possible, in order

to ensure proper draft through the furnace. The

barometric damper must be mounted with the hinge pins

in a horizontal position and the face of the damper

vertical for proper functioning, (see instructions included

with damper). After the furnace has been firing for at

least five minutes, the draft regulator should be set to

between -0.025

"

W.C. and -0.035

"

W.C.;

4. For flue pipe pressure on sidewall installations (SCS),

refer to the Technical Specifications in this manual;

5. The overfire draft, which is taken through the

observation door located in the centre of the front panel

above the burner, is a measurement that is necessary to

determine if there is a blockage in the heat exchanger or

the flue pipe. Refer to the Technical Specifications in

this manual for overfire pressure values. A high

pressure condition may be caused by excessive

combustion air due to the air band being too wide open

or a lack of flue draft (chimney effect) or some other

blockage, such as soot in the secondary section of the

heat exchanger or the use of an oversize nozzle input or

high pressure pump;

6. CO

2

and flue temperature instruments will enable you to

obtain the data that are required to determine the true

efficiency of the furnace. Although this information is

nice to have, it is not essential in the basic set up of the

furnace. The proper procedure for performing this

operation is as follows:

a. Start the appliance and from the test port provided

on the BREECH PLATE (SCS) or on the flue pipe

just before the draft regulator (chimney application),

proceed with the smoke test and adjust the burner

to a setting of between a “trace” and #1 smoke after

5 to 10 minutes of operation;

b. Take a CO

2

reading and mark it down;

c. Open the burner air shutter to get 1.5% CO

2

less

than the previous reading noted in b. above and

take a smoke test on this condition;

d. The new smoke reading should give you a ZERO

smoke reading.

7. A 10-micron (or less) oil filter should be installed as

closely to the burner as possible with all oil burners, but

it is essential for burners with a low firing rate. We

recommend the use of a low pressure drop oil filter with

a capacity greater than that of the fuel pump;

8. On a new installation, the air trapped in the oil line

leading from the tank to the nozzle must be thoroughly

purged in order to prevent excessive after drip. The oil

pump is equipped with a special fitting that facilitates the

purging of any air between it and the tank. The proper

procedure for performing this operation is as follows:

a. Place a piece of 1/4” dia. clear plastic tubing over

the purge fitting on the oil pump;

b. Start the oil burner, then open the purge fitting and

allow the burner to run until the purge tube is

completely free of air bubbles;

c.

At this point tighten the purge fitting, which will allow

the oil to run to the nozzle and fire the burner. If the

purging takes longer than 15 seconds and no flame

has been established the burner will stop. Push the

reset button on top of the Primary Control to restart

the burner.

For detailed information on the operation of the Primary

Control refer to the instructions included with the furnace

or the burner.

Summary of Contents for AMP105-IE2

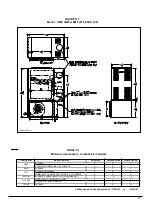

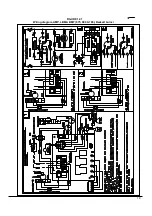

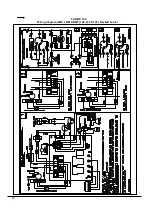

Page 20: ...FIGURE 12 1 Diagramme lectrique AMP LBM BMF 075 090 et 105 br leur Beckett 21...

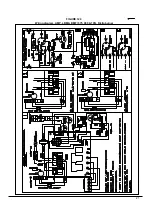

Page 21: ...FIGURE 12 2 Diagramme lectrique AMP LBM BMF 120 140 et 155 br leur Beckett 22...

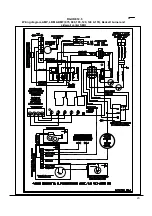

Page 22: ...FIGURE 12 3 Diagramme lectrique AMP LBM BMF 075 090 et 105 br leur Riello 23...

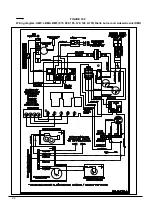

Page 23: ...FIGURE 12 4 Diagramme lectrique AMP LBM BMF 120 140 et 155 br leur Riello 24...

Page 26: ...FIGURE 12 7 Diagramme lectrique AMP LBM BMF 075 090 et 105 br leur B SCS 27...

Page 27: ...FIGURE 12 8 Diagramme lectrique AMP LBM BMF 120 140 et 155 br leur B SCS 28...

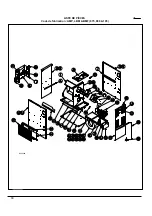

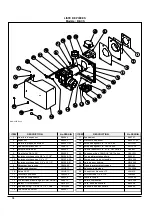

Page 28: ...29 COMPOSANTES ET PI CES DE REMPLACEMENT...

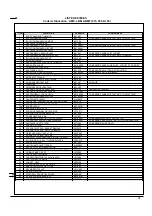

Page 29: ...LISTE DE PI CES Code de fabrication AMP LBM BMF 075 090 105 30 B50058A...

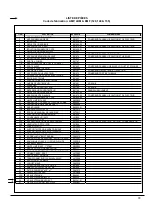

Page 31: ...LISTE DE PI CES Code de fabrication AMP LBM BMF 120 140 155 32 50062A...

Page 51: ...19 FIGURE 12 1 Wiring diagram AMP LBM BMF 075 090 105 Beckett burner...

Page 52: ...20 FIGURE 12 2 Wiring diagram AMP LBM BMF 120 140 155 Beckett burner...

Page 53: ...21 FIGURE 12 3 Wiring diagram AMP LBM BMF 075 090 105 Riello burner...

Page 54: ...22 FIGURE 12 4 Wiring diagram AMP LBM BMF 120 140 155 Riello burner...

Page 57: ...FIGURE 12 7 Wiring diagram AMP LBM BMF 075 090 105 B SCS burner 25...

Page 58: ...FIGURE 12 8 Wiring diagram AMP LBM BMF 120 140 155 B SCS burner 26...

Page 59: ...27 COMPONENTS AND REPLACEMENT PARTS...

Page 60: ...PARTS LIST Model AMP LBM BMF 075 090 105 28 B50058A...

Page 62: ...PARTS LIST Model AMP LBM BMF 120 140 155 30 B50062A...