Monarplan

®

Installation manual

23

062014V1

7.2.2 Monarplan® Coated Metal

7.2.2.1 Complete profile solution

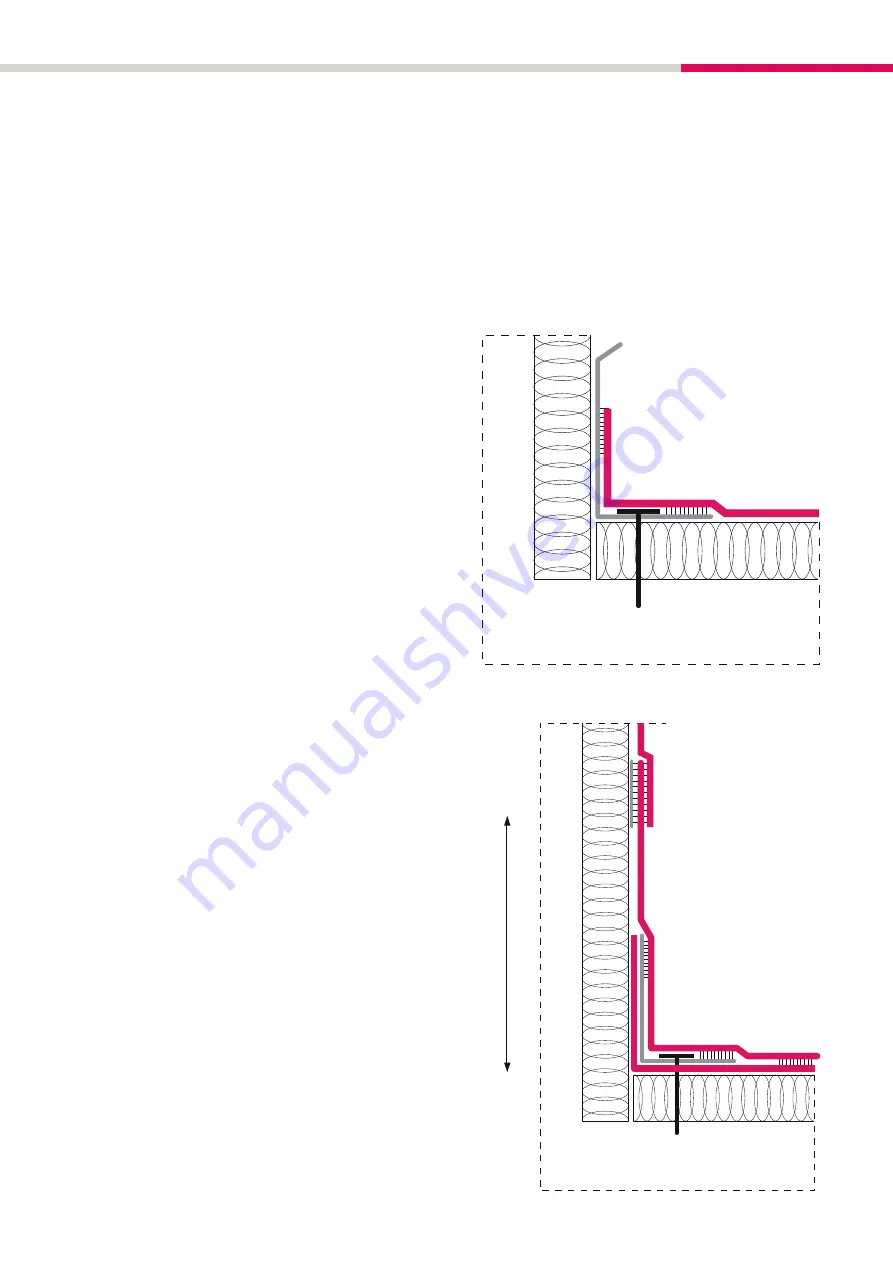

Non-Fleecebacked membrane

The perimeter of the Monarplan® G or FM reinforced membrane

on the field area is welded continuously to the horizontal flange

of a mechanically fastened 90° membrane-coated metal angle.

Fleecebacked Membrane

The perimeter of the Monarplan® GF Fleeceback field membrane

is secured by mechanically fastening a membrane-coated metal

angle to the foot of the upstand. This is then waterproofed using

the Monarplan® (G or FM) non-fleeceback membrane dressed to

the upstand, welding to the field sheet and at least the horizontal

flange of the coated metal angle.

For further clarification regarding the method of perimeter

restraint, refer to the range of Monarplan® Standard Drawings.

7.2.2.2 Angle solution

Where the roof shape changes from a horizontal plane to an angled

or vertical plane, a section of Monarplan® metal profile must always

be used to facilitate this change of direction. The Monarplan®

roofing membrane is cut to fit the horizontal metalsheet plane

and welded to it in the normal way. The metalsheet follows the

change of direction and Monarplan® membrane is cut to fit the

vertical leg of the metalsheet section and welded to it. When a

right angled section of metalsheet is installed, it must only be

fastened to the substrate, in the horizontal plane.

max. 50 cm