The initial physical hardware installation continues with the following steps:

v

“Providing power to the SAN384B” on page 35

v

“Connecting the SAN384B and host with a serial cable” on page 35

v

“Logging in to the serial console port” on page 36

v

“Configuring the IP addresses” on page 36

v

Installing optical transceivers and cables (see “Removing and installing

transceivers” on page 81 and “Managing cables” on page 42)

The following additional steps are customer responsibilities required for the initial

configuration:

1.

Establish an Ethernet connection. See “Establishing an Ethernet connection” on

page 38.

2.

Specify a switch name. See “Customizing the switch name” on page 38.

3.

Specify a domain ID for the SAN384B. See “Setting the Domain ID” on page

39.

4.

Set the date and time. See “Setting the date and time” on page 39.

5.

Connect to the fabric. See “Verifying the PID mode and connecting to the

fabric” on page 41

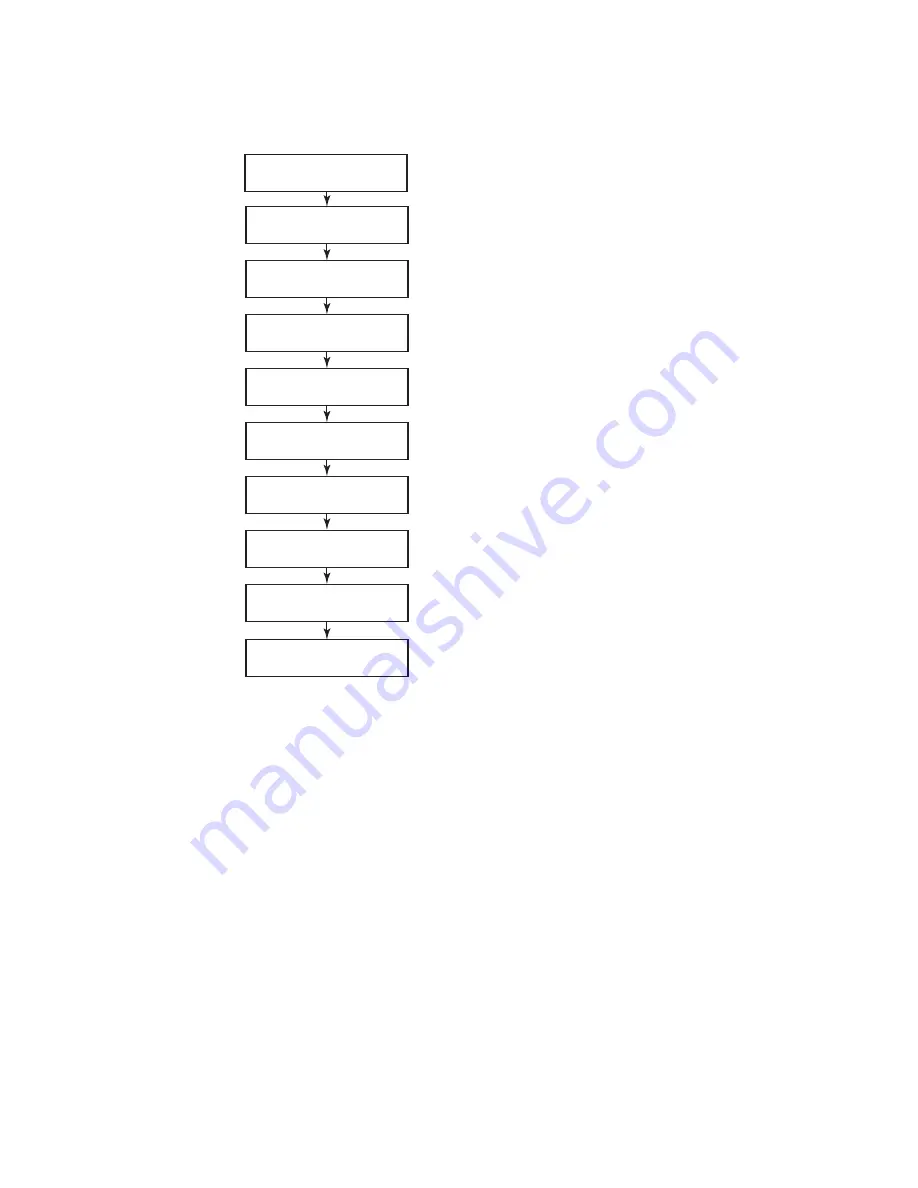

Configuration Tasks

Connect Serial Cable

between Switch and Host

Log In to Serial Console Port

Set IP Address

Log off Serial Console Port

and Disconnect Serial Cable

Connect Ethernet Cable

and Open Telnet Session

Set Domain ID

Set Date and Time

Install SFPs and

Attach Cables

Manage Cables

Verify Operation and

Back Up Configuration

384b004

Figure 17. Flow of configuration tasks for the SAN384B

34

SAN384B Installation, Service, and User Guide

|

|

|

|

Summary of Contents for SAN384B

Page 2: ......

Page 10: ...viii SAN384B Installation Service and User Guide...

Page 12: ...x SAN384B Installation Service and User Guide...

Page 14: ...xii SAN384B Installation Service and User Guide...

Page 28: ...xxvi SAN384B Installation Service and User Guide...

Page 38: ...10 SAN384B Installation Service and User Guide...

Page 60: ...32 SAN384B Installation Service and User Guide...

Page 78: ...50 SAN384B Installation Service and User Guide...

Page 88: ...60 SAN384B Installation Service and User Guide...

Page 146: ...118 SAN384B Installation Service and User Guide...

Page 158: ...130 SAN384B Installation Service and User Guide...

Page 164: ...136 SAN384B Installation Service and User Guide...

Page 168: ...140 SAN384B Installation Service and User Guide...

Page 176: ...148 SAN384B Installation Service and User Guide...

Page 181: ......

Page 182: ...Part Number 45W8160 Printed in USA GC52 1333 02 1P P N 45W8160...