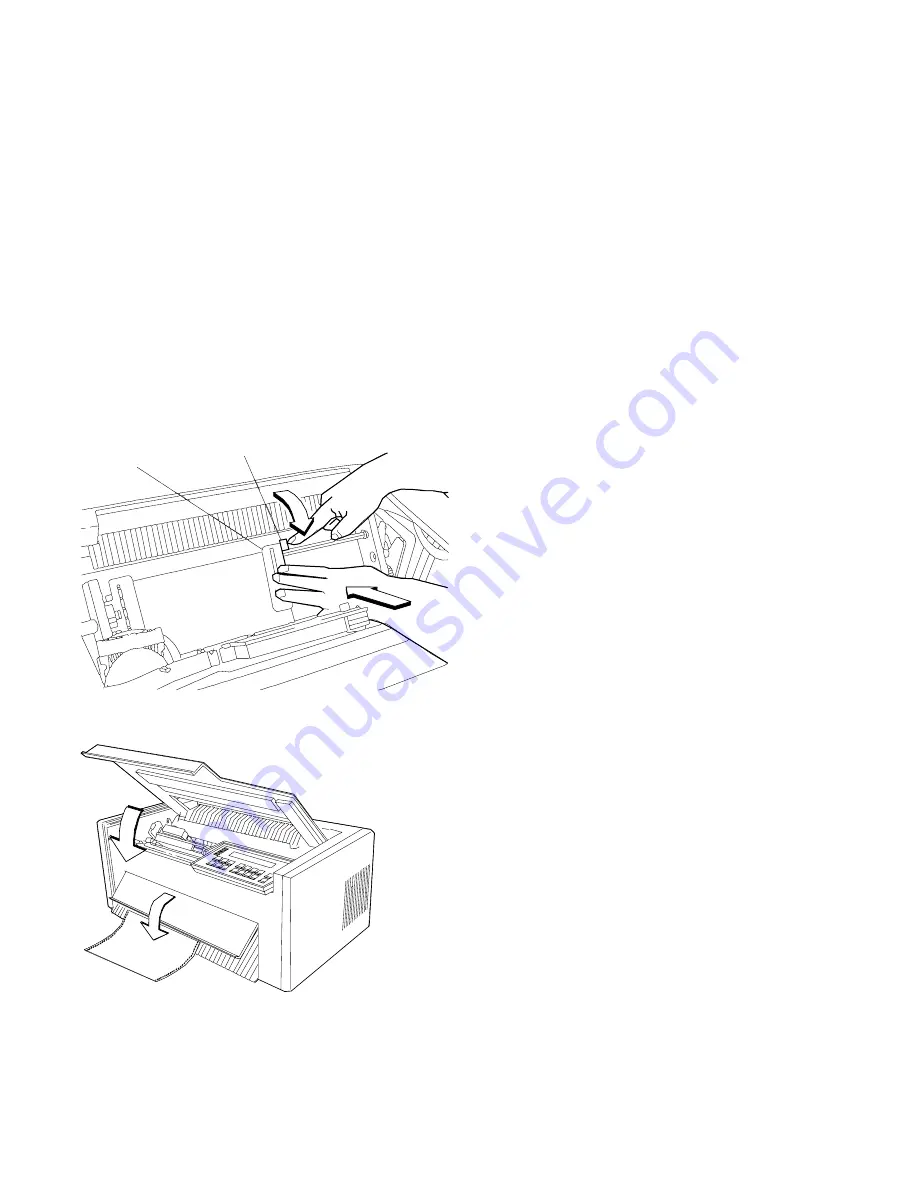

4. Close the right blue tractor door. Hold the tractor in place and

lock the blue locking lever.

Note: If necessary, unlock the tractor and adjust it so that the

forms are not buckled or stretched too tightly.

Blue Tractor

Door

Blue Locking Lever

5. Close the access cover. Then close the paper door by pulling it

out and pushing it down until it latches.

1-28

User’s Guide

Summary of Contents for 4230 - Model 4i3 B/W Dot-matrix Printer

Page 1: ...4230 Printer Models 101 1S2 201 2S2 4S3 and 5S3 User s Guide SA40 0593 04 ...

Page 2: ......

Page 3: ...4230 Printer Models 101 1S2 201 2S2 4S3 and 5S3 User s Guide SA40 0593 04 IBM ...

Page 10: ...viii User s Guide ...

Page 57: ...Chapter 1 Setting Up the 4230 Printer 1 35 ...

Page 71: ...The printer displays Bidirectional Adjustment Chapter 1 Setting Up the 4230 Printer 1 49 ...

Page 89: ...Chapter 1 Setting Up the 4230 Printer 1 67 ...

Page 133: ...The printer displays Bidirectional Adjustment Chapter 1 Setting Up the 4230 Printer 1 111 ...

Page 200: ...4 10 User s Guide ...

Page 211: ... Figure 5 2 Sample Printer Configuration Printout Model 4S3 Chapter 5 Tests 5 11 ...

Page 212: ... Figure 5 3 Sample Printer Configuration Printout Models 201 and 2S2 5 12 User s Guide ...

Page 213: ... Figure 5 4 Sample Printer Configuration Printout Model 5S3 Chapter 5 Tests 5 13 ...

Page 217: ...The printout should look similar to Chapter 5 Tests 5 17 ...

Page 220: ...The sample printout appears as follows 5 20 User s Guide ...

Page 222: ...5 22 User s Guide ...

Page 230: ...A 8 User s Guide ...

Page 278: ...B 48 User s Guide ...

Page 292: ...C 14 User s Guide ...

Page 294: ...D 2 User s Guide ...

Page 308: ...X 8 User s Guide ...

Page 319: ......

Page 320: ...IBM Part Number 1053389 Printed in U S A 1ð53389 SA4ð ð593 ð4 ...