Unpacking the control enclosure

Before you unpack the FlashSystem 5100 control enclosure, ensure that you review and follow all related

instructions.

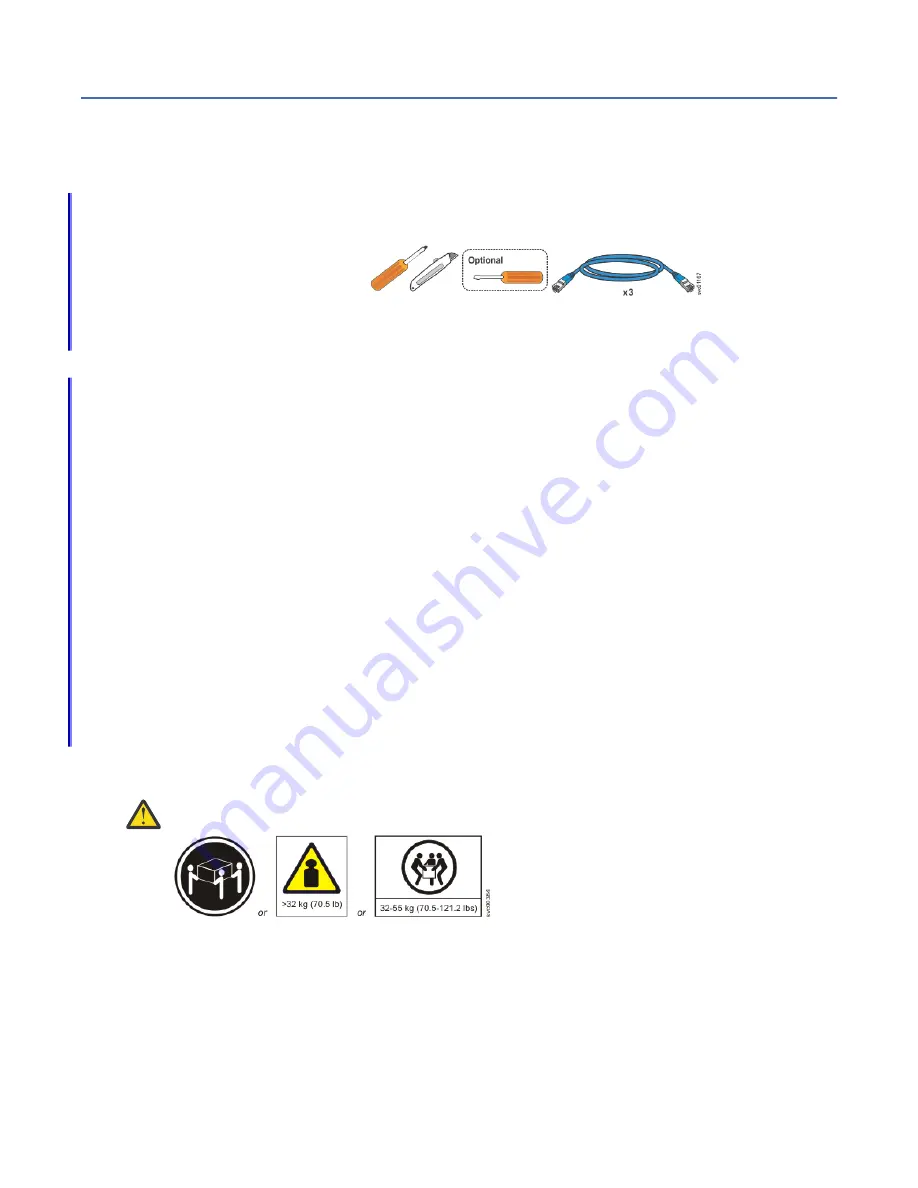

Before you begin

Before you start the installation process, complete the information that is requested in the "Planning

worksheets" in IBM Knowledge Center and ensure the following items are available.

• Philips screw driver

• Box knife

• Flat-blade screw driver

(optional)

• Three Ethernet cables

The control enclosure and the following related parts are included in one box. The enclosed inventory

sheet lists the part numbers of the items that were ordered. Items, such as drives and networking

adapters, are preinstalled inside each node canister.

• Control enclosure with the following components preinstalled:

– Two node canisters with optional networking adapters, SFPs, and memory

Each node canister contains two networking adapter slots. The same number and type of adapters

must be installed in each node canister. The control enclosure can contain 0, 2, or 4 networking

adapters.

– Two power supply units (PSUs)

– A combination of 24 drives and drive blanks

The number of drives and drive blanks varies, according to the number of drives that were specified

in the product order. For example, if 12 drives were ordered, the drives and 12 drive blanks are

preinstalled in the control enclosure.

• Rail kit, which includes the left and right rails, and 8 securing M5 screws and locating pins.

• Cables, if they were ordered, for the type and number of networking adapters that are installed in each

node canister.

• Two power cables.

About this task

CAUTION: The weight of this part or unit is between 32 and 55 kg (70.5 and 121.2 lb). It takes

three persons to safely lift this part or unit. (C010)

To unpack the control enclosure, complete the following steps. If three persons or a lift are not available,

more steps are required to remove some parts before the control enclosure can be installed.

1. Cut the box tape and open the lid of the shipping carton.

2. Remove the rail kit box and set it aside in a safe location.

3. Lift the front and rear foam packing pieces from the carton.

4. Remove the four corner reinforcement pieces from the carton.

10 FlashSystem 5100 : Quick Installation Guide for MTM 2078-4F4, 2078-4H4, 2078-12G, 2078-AFG,

2078-24G, 2078-A9G, 2078-92G, and 2078-UHB

Summary of Contents for 2078-4F4

Page 129: ......

Page 130: ...IBM ...