Master Unit

Slave Devices

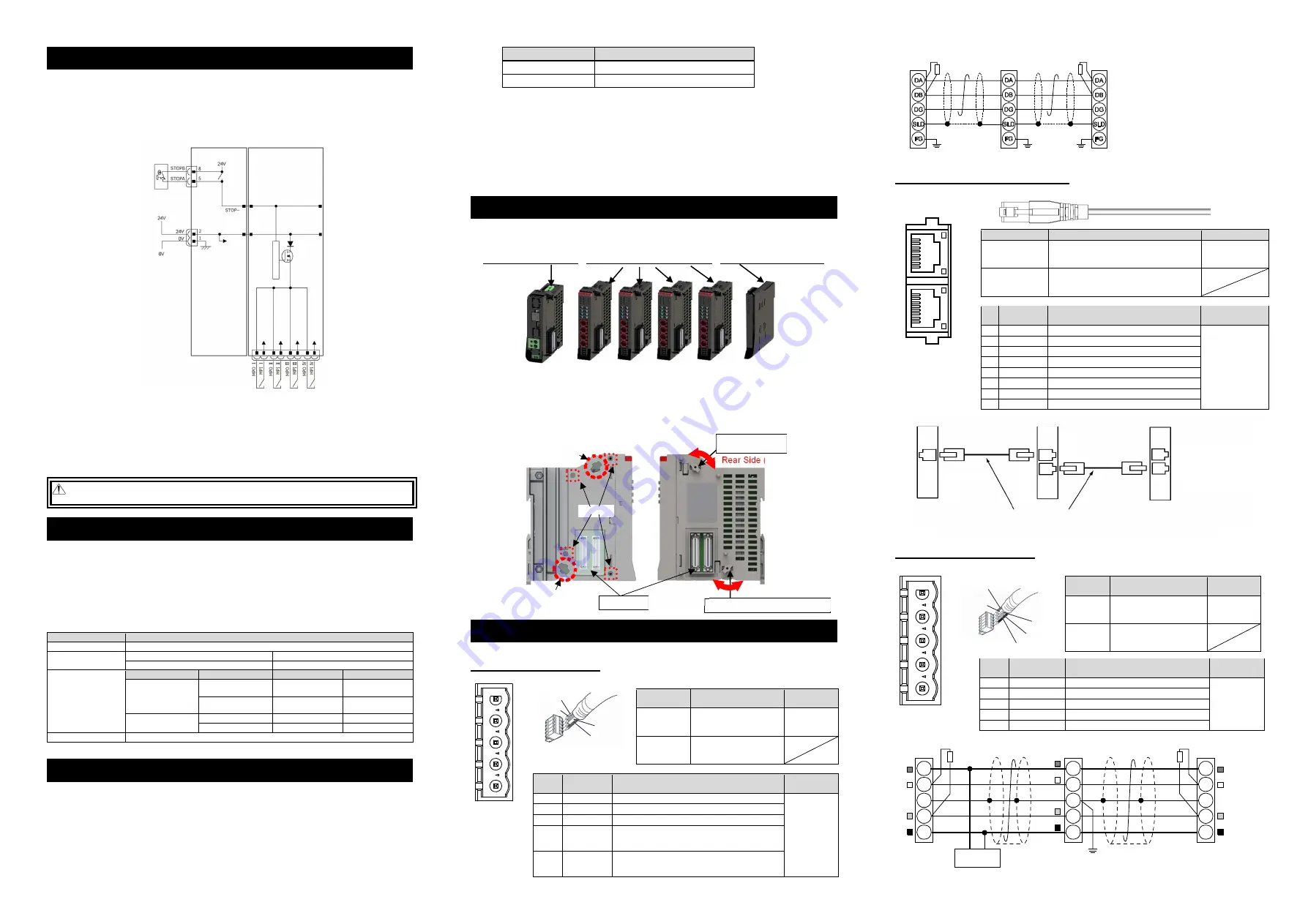

REC CC-Link IE Field Type

Ethernet Straight Cable Category 5e or more

Double shielded cable braided with aluminum foil recommended

(Note) Terminal resistance is not required

There is no

distinction of IN/OUT

on the connector.

Rear Side (Link)

Link Upper Parts

Operation Part

[

C

]

[A]

Link Bottom Parts Operation Part

[B]

Connector

Panel Side (Unlink)

Panel Side

(Unlink)

Rear Side (Link)

Power Supply and Stop Circuit (Example)

In the diagram below shows a circuit related to REC system drive source cutoff. For REC system, 24V power is supplied

from the EC Gateway Unit, but the circuit related to the drive-source cutoff is on the EC Connection Unit side.

•

Each unit of EC Connection Unit possesses a drive cutoff circuit by semiconductor gathered for the four axes, and

the motor power source is to be cut off by the stop switch on the teaching pendant. Also, the drive source cutoff

circuit by semiconductor possesses features to detect the over current and to limit the in-rush current.

•

Each driver unit possesses an interface (Drive source cutoff connector: MPI/MPO) available for external drive

source cutoff prepared for each axis.

Note 1 If nothing is connected to the SIO connector, short-circuit should be made inside the controller.

Note

●

When externally shutting off the motor drive source, connect a contact such as a relay to the wiring between the

MPI* and MPO* terminals.

●

When supplying power by turning ON/OFF 24 VDC, leave 0 V connected and supply/cut off +24 V.

●

Make sure to have the right cable diameter and length that would not have the voltage dropped at the wiring of the

drive cutoff connector.

●

There may be a case of an alarm being generated because of the voltage drop at the controller power supply due to

inappropriate cable diameter or length. In such a case, adjust the output voltage of the power supply to keep 24V for

the supply to the controller.

Warning : Note that the stop switch on the teaching pendant cannot have a stop for the system side even though it

can have a stop for all the actuators connected to REC System.

Current Amperage

The current amperage should be divided into the control power capacity and motor power capacity.

Each power supply should be input from the 24V power supply connector on the EC Gateway Unit.

The necessary capacity of the current amperage should be figured out by [Total of control power capacity of

used units] + [Total of motor power capacity of used actuators].

It is necessary that the rated current of 24V power supply satisfies the rated current of the motor power

capacity and the peak current satisfies the maximum current of the motor power capacity. However, when

several axes get connected, unless all the actuators operates at the same time, the rated current and

maximum current would not flow at the same time, thus the calculation should not be simply the total of all

the axes.

The specifications related to the power capacities should be as shown below.

Note When ELECYLINDER * 4 axes are connected to EC Connection Unit

Restrictions in Unit Connection

(1) Number of EC Connection Units to Connect

The maximum number of control axes to be connected to one EC Gateway Unit should be 16 axes.

From the structural perspective of the unit, it can accept connection without any upper limit, but make it

accept 4 units (for 16 axes) of EC Connection Units at the maximum. (One unit occupies domains and

axis numbers for four axes regardless of whether to connect ELECYLINDER to the units or not.) Have

two EC Gateway Units or more in the construction when it is necessary to control 17 axes or more of actuators.

(2) Current Restrictions

Shown below is the restricting values of current for selecting calculation.

Item

Restricting Value of Current for Selecting Calculation

Control Power Supply (CP)

9.0A or less

Motor Power Supply (MP)

37.5A or less

Shown below is some examples for calculation.

[Control Power Supply] * EC Gateway Unit should be excluded from the target for calculation.

When ELECYLINDER × 16 axes: EC Connection Unit 0.1A × 4 = 0.4A

⇒

OK

[Motor Power Supply]

When ELECYLINDER (with power-saving setting inactivated) × 16 axes:

EC Connection Unit Rated Current 2.3A × 16 axes = 36.8A => OK

Note For the models with no description of the rated current for the motor current amperage, calculate with the

maximum current.

Note When the operation pattern is to have all the axes operate acceleration and deceleration only and the operation

duty is 100%, it is necessary that the calculation is done with the maximum current for the motor power supply.

REC system is capable to link 4 units (for 16 axes) at the maximum with the EC Gateway Unit allocated at

the left end as the interface for the field network connection and freely construct with combination of

multiple EC Connection Units. There is an order of allocation for each unit.

EC Gateway Unit (Left End)

-

EC Connection Unit

(

No Order among

)-

REC Terminal Unit (Right End)

Each unit should be linked in the process shown below. (Make sure it gets linked before connected to the DIN rails.)

1) Twist the operation parts of the link upper parts and the link bottom parts towards the panel side and

place them at the panel side end.

2) Adjust the position of two units so the link upper parts come to Point [A], link bottom parts to [B] and the

four positioning bosses to [C] and all the six points fit to each other.

3) Once positioning is done, firmly insert the connectors at two points.

4) Twist the operation parts of the link upper parts and the link bottom parts towards the rear side till they

make click feeling.

Field Network Wirings and Settings

The field network connector is allocated on the top of the EC Gateway Unit. Refer to “Names for Each Part”.

1. CC-Link (REC-GW-CC)

Refer to the instruction manuals for each field network master unit for the details.

Connector

Name

CC-Link Connector

Remarks

Cable Side

MSTB2.5/5-STF-5.08 AU

(Manufactured by

PHOENIX CONTACT)

Enclosed in

standard

package

Controller Side

MSTB2.5/5-GF-5.08 AU

(Manufactured by

PHOENIX CONTACT)

Pin No.

Signal Name

(Color)

Description

Applicable

cable diameter

1

DA (BL)

Communication Line A

Dedicated

cable for CC-

Link

2

DB (WT)

Communication Line B

3

DG (YW)

Digital Ground

4

SLD

Connect the shield of the shielded cable

(Connected inside to 5-pin FG and control power supply

connector 1-pin FG)

5

FG

Frame Ground

(Connected inside to 4-pin SLD and control power supply

connector 1-pin FG)

2. CC-Link IE Field (REC-GW-CIE)

Refer to the instruction manuals for each field network master unit for the details.

Connector Name

CC-Link IE Field Connector

Remarks

Cable Side

Ethernet ANSI/TIA/EIA-568-B Category 5e

and above 8P8C modular plug equipped

with shield (RJ45)

Please prepare

separately

Controller Side

Ethernet ANSI/TIA/EIA-568-B Category 5e

and above 8P8C modular Jack equipped

with shield (RJ45)

Pin

No.

Signal Name

Description

Applicable cable

diameter

1 TP0+

Data 0+

It is recommended

to prepare a

straight STP cable

in Category 5e or

above for the

Ethernet cable.

2 TP0-

Data 0-

3 TP1+

Data 1+

4 TP2+

Data 2+

5 TP2-

Data 2-

6 TP1-

Data 1-

7 TP3+

Data 3+

8 TP3-

Data 3-

3. DeviceNet (REC-GW-DV)

Refer to the instruction manuals for each field network master unit for the details.

Connector

Name

DeviceNet Connector

Remarks

Cable Side

MSTB2.5/5-STF-5.08 AU M

(Manufactured

by PHOENIX CONTACT)

Enclosed in

standard

package

Controller

Side

MSTB2.5/5-GF-5.08 AU

(Manufactured

by PHOENIX CONTACT)

Pin No.

Signal Name

(Color)

Description

Applicable

cable diameter

1

V- (BK)

Power Supply Cable Negative Side

Dedicated

cable for

DeviceNet

2

CAN L (BL)

Communication Data Low Side

3

-

Shield

4

CAN H (WT)

Communication Data High Side

5

V+ (RD)

Power Supply Cable Positive Side

Item

Specification

Power Supply Voltage

24V DC ±10%

Control Power Capacity

(for one unit)

EC Gateway Unit

0.8A

EC Connection Unit

0.1A

Motor power capacity

(1 axis per actuator)

Motor type

Rated Current

Max. current

35P/42P/56P

When power-saving

setting inactivated

2.3A

3.9A

When power-saving

setting activated

-

2.2A

28P

S3□/RR3□Type

-

2.2A

Slim and Small Type

-

2.0A

In-Rush Current (Note)

40A

(with in-rush current limiting circuit)

Linking Units

Top View of

Connector on

EC Gateway

Unit side

L.ER

LINK

L.ER

LINK

Shield

BL (CAN L)

RD (V+)

WT (CAN H)

BK (V-)

WT (DB)

BL (DA)

Shield (SLD)

YW (DG)

REC Gateway Unit

Control

Power

Stop Switch on

Teaching Pendant

EC

M

ot

or

P

owe

r S

uppl

y

Ⅰ

EC

M

ot

or

P

ow

er

S

up

ply

Ⅱ

EC

M

ot

or

P

ow

er

S

up

ply

Ⅲ

EC

M

ot

or

P

owe

r S

uppl

y

Ⅳ

High-

Sid

e P

rot

ec

tio

n C

irc

uit

Drive Source

Cutoff

Connector

RCON-EC Unit

Note 1

SIO Connector

24V Input

Connector

Slave Devices

REC-

CC-Link

Type

SLD and FG are internally connected.

Terminal Resistance is required

to be mounted on the terminal.

The terminal resistor differs depending on the type

of the dedicated cable for CC-Link.

• Cable FANC-SBH···130

Ω

1/2W

(High Performance Cable

dedicated for CC-Link)

• Cable FANC-SB······110

Ω

1/2W

(CC-Link Dedicated Cable)

Master Unit

Terminal

Resistance

Terminal

Resistance

Grounding resistance at 100

Ω

or less

(Class D grounding)

5

4

3

2

1

Top View of

Connector on

EC Gateway

Unit side

5

4

3

2

1

Top View of

Connector on

EC Gateway

Unit side

Slave Devices

REC-DeviceNet Type

V+

Drain

(Shield)

CAN_H

CAN_L

V-

RD

WT

BL

BK

RD

WT

BL

BK

V+

Drain

(Shield)

CAN_H

CAN_L

Grounding resistance at 100

Ω

or less

(Class D grounding)

V+

Drain

(Shield)

CAN_H

CAN_L

V-

RD

WT

BL

BK

Communication power needs to be

supplied by an external device.

Terminal Resistance is required

to be mounted on the terminal.

V-

Terminal Resistance

121

Ω

Master Unit

Terminal Resistance

121

Ω

24V

Power Supply