SPECIFICATIONS

• E24 Motor Card Requirements

Power Requirements

Power In

•

24.0 VDC nominal @ 3 A maximum

o

Limited to 1.5 A when DIP switch 4 is OFF (see page 15)

Normal operation from 22.0 – 28.0 VDC

Will allow operation above 28.0 VDC but control will get hotter.

Will allow operation below 22.0 VDC but full speed will be

unattainable.

29.0 + 0.2 VDC over-voltage detection (unit will cease normal

o

operation)

19.0 + 0.2 VDC under-voltage detection (unit will cease normal

o

operation)

Polarity protection is provided

o

Note that the control’s ground does not attach to the metal

chassis; doing so assures a solid ground but then if the power

supply is reversed it’s positive output

Fuse to only be replaced with a 5A Slo-Blo Littlefuse 0454005 or

o

equivalent.

NPN/PNP Selectable Inputs

•

– can be either an NPN or PNP input

(see page 14) PNP is recommended.

NPN Input Signal Levels (When switch 2 is OFF)

o

Active when pulled down below 2.0 VDC

Need to be able to sink 3 mA

PNP Input Signal Levels (When switch 2 is ON)

o

Active when pulled up above 18.0 VDC

Need to be able to source 3 mA

Two input signals (See page 14)

o

Motor Run

Motor Reverse

Analog Speed Input

•

Allow the speed to be controlled from a single point

Voltage range: 0-10 VDC

Minimum impedence presented to input: 5K

PNP Output

•

Signal Levels

o

Sources current when active

Maximum current for this unprotected output is 50mA.

A 150Ω series resistor helps the PNP output limit current draw

for most situations; voltage out is thus lower as current draw

increases.

Voltage dependent on input power and current draw.

One output signal (See Page 14)

o

Motor Running

Environmental Requirements

Temperature

•

The unit shall operate within specified limits over the range of -20

o

to 40 °C (-4 to 120 °F).

The unit can be stored in the range of -40 to 85 °C (-40 to 185 °F).

o

Humidity

•

The unit shall operate within specified limits in relative humidity in

o

the range of 20 to 90% (non-condensing).

The unit can be stored in the range of 5 to 95% (non-condensing).

o

Safety – Unintended Use Considerations

Installer

•

This product is intended for installation by qualified personnel

o

only; although of relatively low voltage there are dangerous levels

of current controlled on the board that are not protected from

misplaced fingers.

Note that the cover makes it difficult to touch any power other

than the fuse.

A tool will be required to tweak the pot or move the DIP

switches; a plastic-tip screwdriver is recommended.

Should the on-board fuse require replacement always use only that

o

detailed in this specification.

User

•

Product shall be located away from the user such that touching of

o

the control is not possible.

Should the on-board fuse require replacement always use only that

o

detailed in this spec.

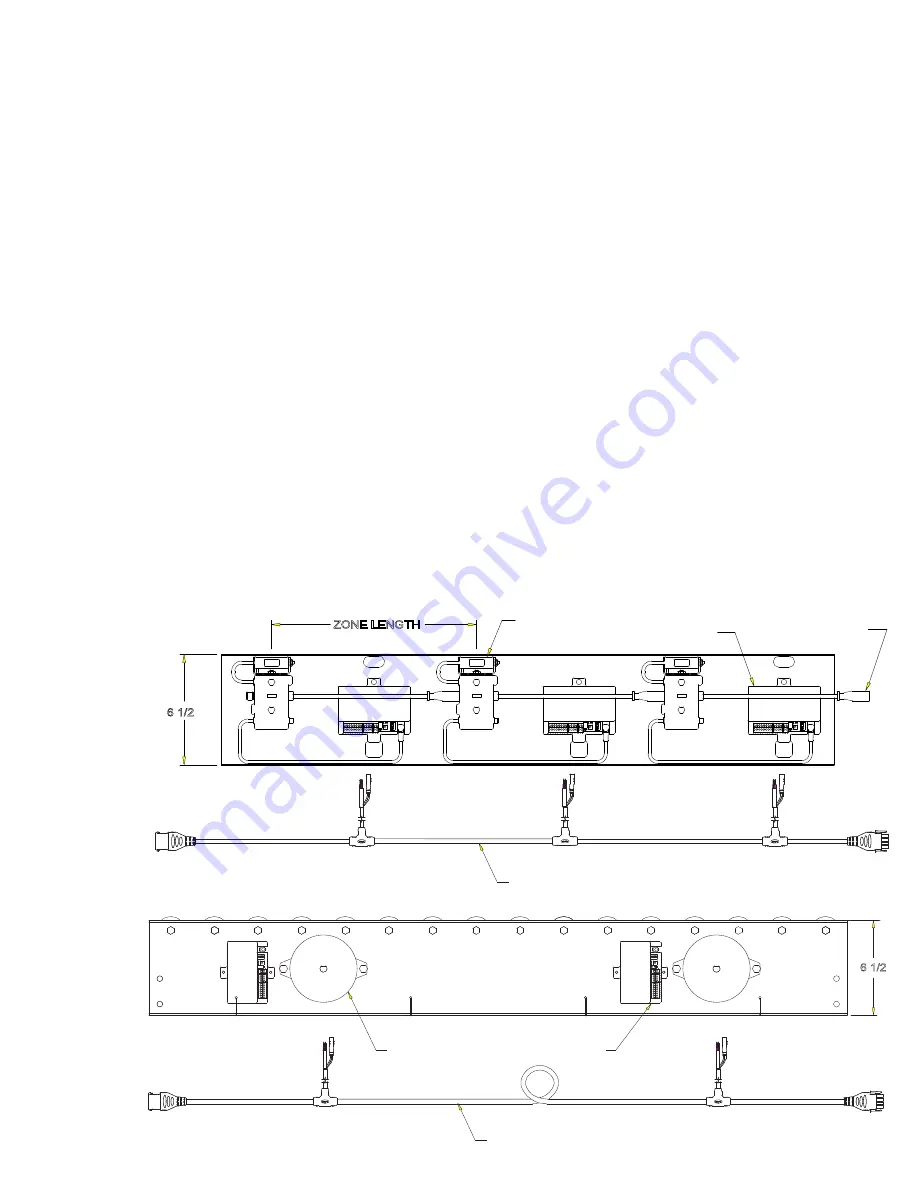

6 1/2

Unidrive Motor Control

Unidrive Motor

Wiring Harness W/Drops

Figure 13B

• E24 Connections

6 1/2

ZONE LENGTH

Zone Controller

Unidrive Motor Control

Cordset

Figure 13A

Wiring Harness W/Drops

• E24EZ Connections

13