INSTALLATION

• Support Installation

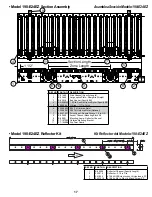

1. Determine primary direction of product flow. Figure 4A

indicates the preferred flow as related to the drive.

2. Refer to “Match-Mark” numbers on ends of conveyor

sections. (Figure 4A) Position them in this sequence near

the area of installation.

3. Attach supports to both ends of drive section and to one

end of intermediate or tail sections (Figure 4A and 4C).

Hand tighten bolts only at this time.

4. Adjust elevation to required height.

• Ceiling Hanger Installation

If conveyors are to be used in an overhead application,

ceiling hangers may have been supplied in place of floor

supports.

Figure 4B shows how a ceiling hanger mounts to a conveyor section. Ceiling

hangers should be mounted at section joints. For safety information concerning

conveyors mounted overhead, refer to “Installation Safety Precautions” on Pg 3.

• Conveyor Set-Up

1. Mark a chalk line on the floor to locate the center of the conveyor.

2. Place the infeed section in position.

3. Place the remaining sections on the extended support of the previous section

(figure 4A).

4. Fasten the sections together with splice plates and pivot plates (figure 4C).

Hand tighten the bolts only at this time.

5. Insure that all bed sections are square. Refer to page 5 for instructions on how

to square the beds.

6. Tighten all splice plate and support mounting bolts and lag the conveyor to the

floor.

7. Connect the power wires and the EzLogic® zone controller cordsets (where

applicable) at the sections joints.

8. Mount the power supply (for the motor) and IOP (for the EzLogic® System

- where applicable) to the conveyor, near the center. Connect AC power to

both. Connect E24 wiring harness to the power supply, and from the IOP to the

EzLogic® System (where applicable). See page 6 for more information about

these connections

NOTE: See the EzLogic® GEN3 Component Manual for more information

about the IOP power connections and for more information about EzLogic®

components.

9. Install and wire any auxiliary cables or I/O modules. Refer to pages 6 and 7 for

more information about auxiliary connections.

• Electrical Equipment

CONTROLS

Electrical Code: All motor controls and wiring shall conform to the National

Electrical Code (Article 670 or other applicable articles) as published by the

National Fire Protection Association and as approved by the American Standards

Institute, Inc.

CONTROL STATIONS

A) Control stations should be so arranged and located that the operation of the

equipment is visible from them, and shall be clearly marked or labeled to indicate

the function controlled.

B) A conveyor which would cause injury when started shall not be started until

employees in the area are alerted by a signal or by a designated person that the

conveyor is about to start.

When a conveyor would cause injury when started and is automatically

controlled or must be controlled from a remote location, an audible device shall

be provided which can be clearly heard at all points along the conveyor where

personnel may be present. The warning device shall be actuated by the controller

device starting the conveyor and shall continue for a required period of time

before the conveyor starts. A flashing light or similar visual warning may be used

in conjunction with or in place of the audible device if more effective in particular

circumstances.

Where system function would be seriously hindered or adversely affected by

the required time delay or where the intent of the warning may be misinterpreted

(i.e., a work area with many different conveyors and allied devices), clear, concise,

and legible warning shall be provided. The warning shall indicate that conveyors

and allied equipment may be started at any time, that danger exists, and that

personnel must keep clear. The warnings shall be provided along the conveyor at

areas not guarded by position or location.

C) Remotely and automatically controlled conveyors, and conveyors where

operator stations are not manned or are beyond voice and visual contact from drive

areas, loading areas, transfer points, and other potentially hazardous locations on

the conveyor path not guarded by location, position, or guards, shall be furnished

with emergency stop buttons, pull cords, limit switches, or similar emergency stop

devices.

All such emergency stop devices shall be easily identifiable in the immediate

vicinity of such locations unless guarded by location, position, or guards. Where

the design, function, and operation of such conveyor clearly is not hazardous to

personnel, an emergency stop device is not required.

The emergency stop device shall act directly on the control of the conveyor

concerned and shall not depend on the stopping of any other equipment. The

emergency stop devices shall be installed so that they cannot be overridden from

other locations.

D) Inactive and unused actuators, controllers, and wiring should be removed from

control stations and panel boards, together with obsolete diagrams, indicators,

control labels, and other material which serve to confuse the operator.

NOTE: When installing ceiling hanger rods in an existing building, all methods

of attachment must comply with local building codes.

CEILING HANGER ROD

(VARILLA COLGADA

DEL TECHO)

SPACER

(ESPACIADOR)

JAM NUT

(CONTRA TUERCA)

SUPPORT PIPE

(SOPORTE ESTACIONARIO)

JAM NUT

(CONTRA TUERCA)

MOUNTING BOLTS

(TORNILLOS DE MONTAJE)

SIDE CHANNEL

(CANAL LATERAL)

PIPE RETAINER

(ABRAZADERA)

LOCK BOLT

(TORNILLO CANDADO)

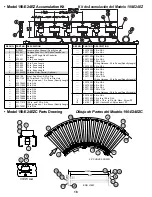

SPLICE PLATE

(SPLICE PLATE)

SIDE CHANNEL

(CANAL LATERAL)

MOUNTING BOLT

(TORNILLO DE MONTAJE)

SIDE CHANNEL

(CANAL LATERAL)

SPLICE PLATE

(PLACA DE EMPALME)

PIVOT PLATE

(PLACA PIVOTE)

STATIONARY SUPPORT

(SOPORTE ESTACIONARIO)

CONVEYOR

ITEM TO

HYTROL CONVEYOR CO. INC.

JONESBORO, AR

A

1

2

CONVEYOR

ITEM TO

HYTROL CONVEYOR CO. INC.

JONESBORO, AR

A

2

1

FIGURE 4A

4”

Adjust to Desired

Elevation

(ajuse la elevacion

a la altura requerida)

Match-Mark Numbers

(etiquetas de secuencia la de armado)

FIGURE 4B

FIGURE 4C

4