3-10

S

ETUP

Operator Manual

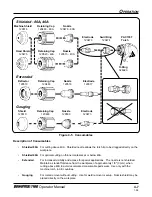

Additional Air Filtration

Use a three-stage coalescing filtration system as shown in Fig. 3-12 when site conditions introduce

moisture, oil or other contaminants into the air line.

Nitrogen Supply Quality

Nitrogen must be supplied to the Powermax1100 at 99.995% purity. If the purity level of the nitrogen is

too low, cut speeds decrease, cut quality deteriorates, cutting thickness capability decreases, and parts

life shortens. (Note: These conditions also occur if there are leaks in the gas supply hoses or

connections.) The nitrogen supply can be compressed gas cylinders or liquid containers.

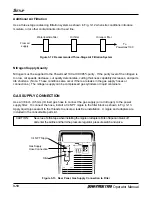

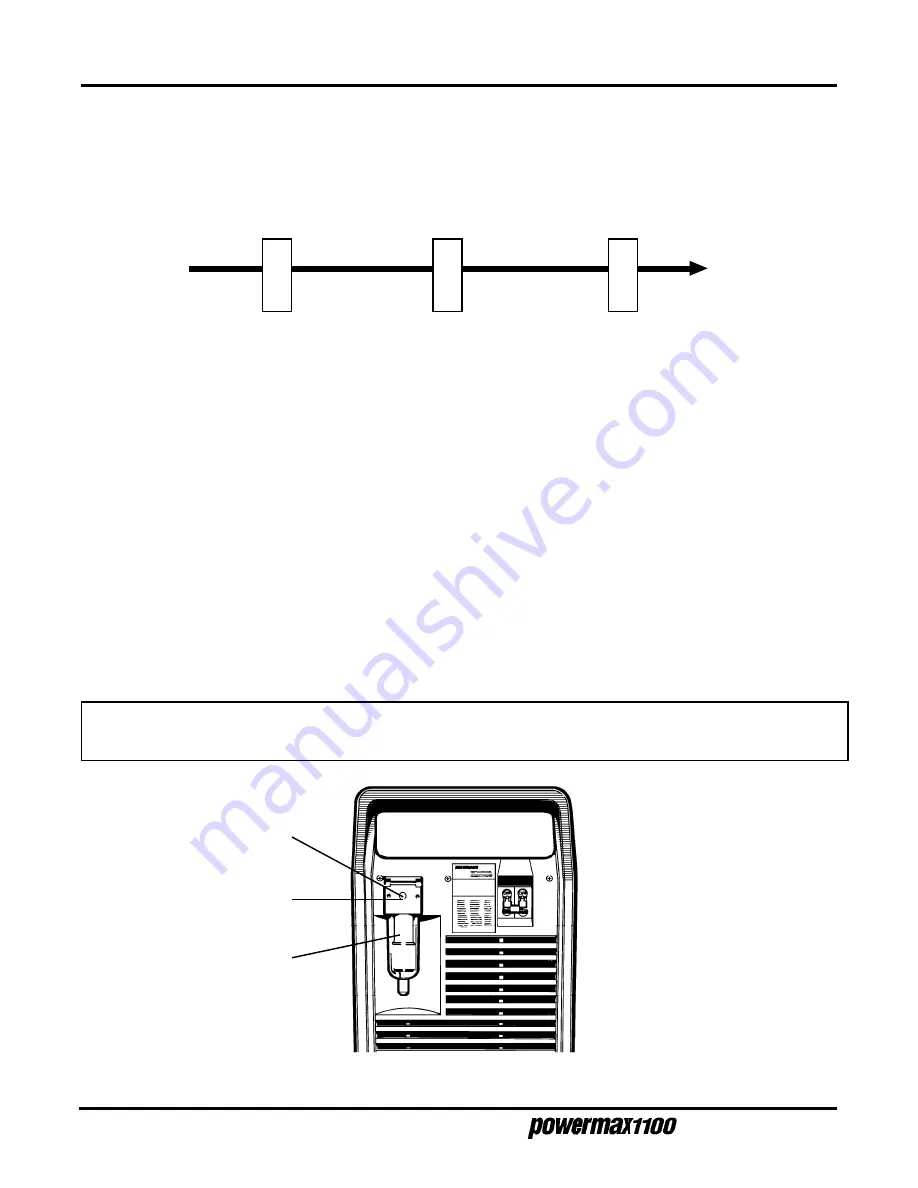

GAS SUPPLY CONNECTION

Use a 3/8 inch (9.5 mm) ID inert gas hose to connect the gas supply (air or nitrogen) to the power

supply filter. To connect the hose, install a 1/4 NPT nipple to the filter block as shown in Fig. 3-13.

Apply liquid pipe sealant to the threads to ensure a leak-free installation. A nipple and adapters are

included in the consumable parts kit.

CAUTION:

Never use Teflon tape when installing the nipple or adapters. Bits of tape can break off

and enter the air line and harm the pressure regulator, pressure switch and valve.

Figure 3-13 Rear Panel, Gas Supply Connection to Filter

Filter

From air

supply

To

Powermax1100

Water/particle filter

Oil filter

Oil vapor filter

Figure 3-12 Recommended Three-Stage Air Filtration System

1/4 NPT Nipple

Gas Supply

Hose Connection